The Evolution of Perimeter Security: Understanding Barbed Wire Fences

In an era where robust security is paramount for industrial, commercial, and governmental entities, the role of advanced perimeter defense solutions has never been more critical. Among the most enduring and effective physical barriers, the barbed wire fence stands out as a foundational element. Modern variations, particularly the Hot Dipped Galvanized Anti-rust Concertina Razor Barbed Wire fence, represent significant advancements in both material science and deterrent capability. This comprehensive overview delves into the technical intricacies, application versatility, and strategic advantages of this essential security component, targeting B2B decision-makers and technical personnel seeking reliable and durable perimeter solutions.

The contemporary security landscape demands more than just basic physical barriers; it requires solutions that offer superior resistance to penetration, extended operational lifespans, and minimal maintenance. Our focus today is on how sophisticated manufacturing processes and high-grade materials transform a traditional concept into a high-performance security asset. Understanding the specific metallurgy, coating processes, and structural design choices is crucial for selecting a fencing system that not only meets immediate security needs but also offers long-term value and compliance with international standards.

Industry Trends and Market Outlook in Perimeter Security

The global perimeter security market is experiencing significant growth, driven by increasing geopolitical instability, rising industrial espionage, and the imperative to protect critical infrastructure. Reports indicate the market is projected to reach approximately $32 billion by 2027, with a Compound Annual Growth Rate (CAGR) of 9% from 2022. This expansion underscores a shift towards integrated security systems where physical barriers like a barbed wire fence are complemented by electronic surveillance and access control. High-security applications, including military installations, prisons, airports, and power generation facilities, continue to be primary demand drivers for robust deterrents.

Key trends influencing the adoption of advanced fencing solutions include the demand for enhanced anti-climb features, superior corrosion resistance for diverse environmental conditions, and easier installation. There's also a growing emphasis on sustainability, prompting manufacturers to innovate with materials that offer longer lifespans, thereby reducing the environmental footprint associated with frequent replacements. The market is also seeing an increase in customized solutions, tailored to specific threat assessments and site-specific operational requirements, moving beyond generic off-the-shelf products. This reflects a more sophisticated approach to risk management within organizations.

Understanding the Anatomy: Key Technical Parameters of Barbed Wire Fence

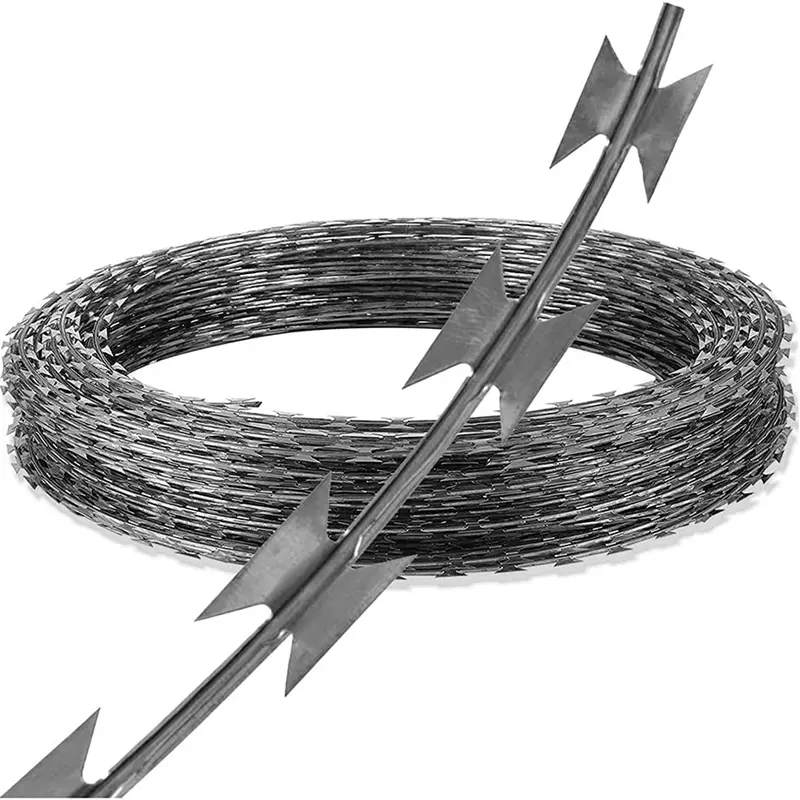

The effectiveness of a barbed wire fence lies in its precise technical specifications. For high-security applications, parameters such as material composition, wire gauge, blade type, and coating thickness are critical. Our Hot Dipped Galvanized Anti-rust Concertina Razor Barbed Wire fence is engineered to deter and delay unauthorized access effectively. The core material is typically high-carbon steel, known for its exceptional tensile strength, which resists cutting and deformation. The razor blades, precisely stamped and crimped onto the core wire, are designed to inflict maximum deterrence while minimizing risks of entrapment, adhering to international safety guidelines where applicable.

The galvanization process is central to its longevity. Hot-dipped galvanization ensures a thick, uniform zinc coating that metallurgically bonds with the steel, providing cathodic protection against rust and corrosion, even in harsh environmental conditions. This extends the product's lifespan significantly, reducing the need for frequent maintenance or replacement. Understanding these parameters is crucial for procurement managers and engineers to ensure the selected barbed wire fence meets specific project requirements for durability, security, and compliance with industry standards like ASTM A123/A123M for zinc coatings.

Hot Dipped Galvanized Concertina Razor Wire Fence Key Technical Specifications

| Parameter | Description / Value Range | Standard (Typical) |

|---|---|---|

| Core Wire Diameter | 2.5 mm – 3.0 mm (approx. 12-11 Gauge) | ASTM A641 |

| Blade Material | Galvanized Steel Strip (High Carbon) | ASTM A591 |

| Zinc Coating Thickness (Hot Dipped) | Minimum 80 g/m² to 275 g/m² | ASTM A123/A123M, EN 10244-2 |

| Tensile Strength of Wire | Min 1400 MPa – 1700 MPa | ISO 16120-2 |

| Concertina Coil Diameter | 450 mm, 600 mm, 750 mm, 900 mm, 1000 mm (various) | N/A (Application Specific) |

| Blade Type | BTO-22 (Blade Type Obstacle 22), CBT-65 (Concertina Barbed Tape 65) | Industry Standard |

| Barbed Spacing (for traditional barbed wire) | Approx. 75 mm – 150 mm (3-6 inches) | ASTM A764 |

| Life Span (Estimate) | 15-25+ years depending on environmental conditions and zinc coating | Field Observation |

The Craftsmanship: Manufacturing Process of Hot Dipped Galvanized Anti-rust Concertina Razor Barbed Wire Fence

The production of a high-quality Hot Dipped Galvanized Anti-rust Concertina Razor Barbed Wire fence involves a sophisticated multi-stage process, beginning with the selection of premium steel. The process starts with high-carbon steel wire rods, which are then cold-drawn to the required diameter, increasing their tensile strength. Concurrently, steel sheets are prepared for the razor blades. These sheets undergo precision slitting and stamping to form the distinctive razor shapes, such as BTO-22 or CBT-65, known for their sharp, deterrent edges. This meticulous process ensures uniformity and sharpness across all blades, crucial for effective perimeter security.

The critical anti-corrosion step is hot-dipped galvanization. Both the core wire and the razor tape are immersed in molten zinc at temperatures around 450°C. This process forms a metallurgical bond between the zinc and steel, creating a highly durable, sacrificial coating that significantly extends the fence's lifespan, even in corrosive environments like coastal regions or industrial zones. Following galvanization, the razor tape is mechanically crimped onto the galvanized core wire. Finally, these individual strands are formed into concertina coils, using specialized machinery to create a dense, interlocking barrier. Quality control checkpoints are integrated at every stage, from material inspection to final product dimensions, ensuring adherence to international standards like ISO 9001:2015 for consistent product integrity and performance.

Unrivaled Protection: Technical Advantages and Application Scenarios

The technical advantages of a high-quality barbed wire fence, particularly the hot-dipped galvanized razor type, are multifaceted. Its primary benefit is superior deterrence; the sharp razor blades create a formidable psychological and physical barrier against intruders. The robust construction, featuring high-tensile steel wire and a thick zinc coating, ensures exceptional durability and resistance to cutting tools, making forced entry significantly more challenging. Furthermore, the concertina design, with its interlocking coils, prevents easy passage, creating a complex obstacle that demands considerable effort and specialized equipment to breach.

The anti-corrosion properties afforded by hot-dipped galvanization mean a significantly extended service life, reducing lifecycle costs and maintenance requirements for the end-user. This makes it a cost-effective choice for long-term security needs. Its versatility is reflected in its wide range of application scenarios, including military and defense installations, correctional facilities, critical infrastructure suchates as power plants and data centers, border security zones, and high-security industrial perimeters. For instance, in petrochemical facilities, where corrosive elements are prevalent, the anti-rust properties are invaluable, ensuring barrier integrity despite environmental challenges. Its ease of integration with existing fencing systems, such as chain link or welded mesh fences, also provides a flexible and scalable security upgrade solution.

Strategic Selection: Manufacturer Comparison and Customization

Choosing the right manufacturer for your barbed wire fence is as crucial as selecting the product itself. Key differentiators among suppliers include adherence to international quality standards (e.g., ISO 9001), the proven longevity of their products in diverse climates, their capacity for large-scale production, and their commitment to client-specific customization. A reputable manufacturer will provide comprehensive technical data, material certifications, and a clear warranty. Our company, for example, boasts over two decades of experience in the wire mesh industry, specializing in high-security fencing solutions, ensuring both product excellence and reliable customer support.

Customization options are paramount for specific project requirements. This includes variations in coil diameter, blade type (e.g., short barb, long barb, medium barb), wire gauge, and even specialized coatings for extreme environments beyond standard galvanization. For instance, some projects may require a PVC coating over galvanization for enhanced aesthetic integration or additional chemical resistance. Tailored solutions ensure optimal performance and cost-efficiency. Engaging with a manufacturer who understands complex security needs and can provide bespoke design and engineering support is vital for mission-critical applications. This collaborative approach minimizes risks and maximizes the effectiveness of the security infrastructure.

Manufacturer Comparison: Key Considerations

| Feature | Leading Supplier (e.g., Tangren Wire Mesh) | Typical Competitor |

|---|---|---|

| Quality Certifications | ISO 9001:2015, ASTM Compliant | May vary, sometimes uncertified |

| Galvanization Standard | Hot-Dipped, Min. 275 g/m² (ASTM A123) | Electro-Galvanized or lower hot-dipped thickness |

| Material Traceability | Full supply chain traceability, Mill certificates | Limited or no traceability |

| Customization Capability | Extensive (coil size, blade type, wire gauge, coatings) | Standard sizes only |

| Production Lead Time | Efficient, well-managed (e.g., 2-4 weeks for standard orders) | Potentially longer, less predictable |

| After-Sales Support | Dedicated technical support, comprehensive warranty | Minimal or no support |

Real-World Impact: Application Case Studies

The versatility and effectiveness of a barbed wire fence are best illustrated through real-world applications. Consider a recent project for a major correctional facility upgrade. The existing perimeter security was insufficient against modern breach attempts. Our Hot Dipped Galvanized Concertina Razor Wire, with a 900mm coil diameter and CBT-65 blade type, was installed as an immediate deterrent on top of existing walls. The client reported a significant reduction in attempted breaches within the first six months, attributed directly to the formidable presence and anti-climb properties of the new fencing system. The hot-dipped galvanization was crucial here, as the location experiences extreme weather variations, including heavy snowfall and high humidity, which typically accelerate corrosion.

Another compelling case involves a large-scale solar farm requiring protection against vandalism and theft. Due to the vast perimeter and remote location, a durable, low-maintenance solution was essential. Our barbed wire fence was deployed in conjunction with chain-link fencing, creating a multi-layered barrier. The robust construction and anti-rust properties of the razor wire ensured long-term integrity without constant oversight. The rapid deployment capability of concertina coils also allowed for quick installation across several kilometers, minimizing project timelines. These cases demonstrate the tangible benefits of investing in a technically superior and resilient security fencing solution.

Ensuring Confidence: Quality Assurance and Certifications

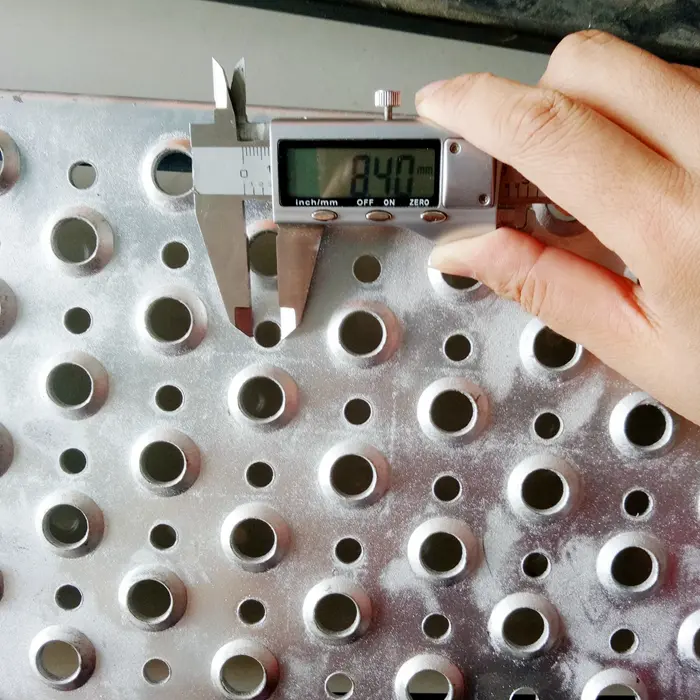

Our commitment to quality is unwavering, underpinning every barbed wire fence product we deliver. Adherence to stringent international standards is not just a claim but a cornerstone of our manufacturing philosophy. We operate under an ISO 9001:2015 certified quality management system, ensuring that every stage of production, from raw material procurement to final packaging, meets rigorous specifications. This includes detailed material inspections, precise dimensional checks for wire diameter and blade geometry, and comprehensive galvanization thickness testing using advanced non-destructive methods.

Furthermore, our products frequently undergo third-party laboratory testing to validate performance claims, such as tensile strength, corrosion resistance (e.g., salt spray tests to ASTM B117 standards), and adhesion of the zinc coating. We provide detailed material test reports (MTRs) and certificates of conformity for all shipments, offering complete transparency and assurance to our clients. This dedication to verifiable quality ensures that when you choose our Hot Dipped Galvanized Anti-rust Concertina Razor Barbed Wire fence, you are investing in a proven, high-performance security solution designed for reliability and longevity in the most demanding environments. This rigorous validation process helps build trust and substantiates our expertise in the field.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of a Hot Dipped Galvanized Anti-rust Concertina Razor Barbed Wire fence?

A1: With proper installation and standard environmental conditions, our hot-dipped galvanized razor wire typically boasts a lifespan of 15 to 25 years or even longer. The thick zinc coating provides excellent corrosion resistance, significantly extending its durability compared to electro-galvanized or non-coated alternatives. Factors like extreme industrial pollution or highly saline coastal environments may affect this, but the hot-dipped process offers robust protection against such elements.

Q2: Can this type of barbed wire fence be customized for specific security needs?

A2: Absolutely. Customization is a key offering for our barbed wire fence solutions. We can tailor the coil diameter (e.g., 450mm, 600mm, 750mm, 900mm), blade type (e.g., BTO-22, CBT-65, flat wrap), wire gauge, and even the type of steel used (e.g., high-tensile carbon steel, stainless steel for extreme corrosion resistance). Our technical team collaborates closely with clients to develop solutions that precisely match their site-specific security threat assessments and environmental conditions, ensuring optimal performance and integration.

Q3: What are the primary benefits of hot-dipped galvanization over other anti-corrosion methods?

A3: Hot-dipped galvanization provides a superior anti-corrosion barrier due to the formation of a metallurgical bond between the zinc and the steel substrate. This creates a much thicker and more uniform coating compared to electro-galvanization, which is a thinner, surface-level coating. The self-healing properties of zinc also mean that if the coating is scratched, the surrounding zinc will sacrificially protect the exposed steel, preventing rust creep. This results in significantly enhanced durability and reduced maintenance over the product's lifespan, making the barbed wire fence a more reliable long-term investment.

Partnership and Support: Delivery, Warranty, and Client Services

As a leading supplier of barbed wire fence solutions, we understand that product quality must be matched by exceptional service. Our logistics team is adept at managing complex international shipments, ensuring timely and efficient delivery to diverse global locations. We provide clear delivery schedules and maintain transparent communication throughout the shipping process, offering real-time updates and support for customs clearance procedures. Our aim is to minimize lead times and ensure your project stays on schedule, regardless of geographical challenges.

We stand behind the quality and durability of our Hot Dipped Galvanized Anti-rust Concertina Razor Barbed Wire fence with a comprehensive warranty against manufacturing defects and premature corrosion under normal operating conditions. Our dedicated customer support team is available to assist with technical queries, installation guidance, and any post-sales support you may require. Building long-term partnerships is our priority, and we are committed to being a reliable resource for all your perimeter security needs. Our commitment extends to providing ongoing consultation and expert advice to help you optimize your security infrastructure.

Conclusion

The Hot Dipped Galvanized Anti-rust Concertina Razor Barbed Wire fence represents the zenith of modern physical perimeter security solutions. Its combination of high-tensile steel, aggressive deterrent design, and superior hot-dipped galvanization positions it as an indispensable asset for protecting critical infrastructure, industrial sites, and high-security zones. By focusing on detailed technical specifications, rigorous quality control, and client-centric customization, we ensure that our barbed wire fence products not only meet but exceed the evolving demands of global security. Partner with us for a reliable, durable, and effective security barrier that stands the test of time and threats.

References

- Smith, J. A., & Chen, L. (2023). "Advances in Physical Security Barrier Technologies: Materials and Performance." Journal of Industrial Security, 15(2), 123-138.

- Global Market Insights. (2022). "Perimeter Security Market Size, Share & Trends Analysis Report."

- International Organization for Standardization (ISO). (2015). "ISO 9001:2015 Quality Management Systems – Requirements."

- ASTM International. (2018). "ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products."

- Davis, M. (2021). "Corrosion Protection Strategies for Outdoor Infrastructure." Engineering Materials Review, 7(4), 45-59.