The Indispensable Role of reinforcement wire in Modern Infrastructure

In the dynamic landscape of modern construction and civil engineering, the integrity and longevity of structures hinge critically on foundational components, among which reinforcement wire stands out as an indispensable element. This material, often integrated into mesh formations like galvanized reinforcing mesh or galvanised reinforcing mesh, is not merely a supplementary component but a vital contributor to the tensile strength and overall durability of concrete structures, mitigating inherent weaknesses of concrete in tension. Current industry trends emphasize enhanced material performance, sustainability, and sophisticated digital modeling for structural analysis. The drive towards taller, more resilient, and environmentally conscious buildings, along with the escalating demand for robust infrastructure projects such as high-speed rail networks, extensive bridge systems, and expansive industrial complexes, consistently underscores the escalating importance of high-quality reinforcement wire. Manufacturers are now challenged to innovate, providing solutions that not only meet stringent structural requirements but also offer superior corrosion resistance, ease of installation, and cost-effectiveness over the entire lifecycle of the project. This evolution is mirrored in the design and engineering phases, where precise specifications for reinforcement wire are paramount to ensuring structural integrity against various stressors, including seismic activity, extreme weather conditions, and cumulative operational loads. Understanding the material science, manufacturing precision, and practical applications of this critical component is essential for all stakeholders involved in contemporary construction, from architects and structural engineers to procurement specialists and project managers, who collectively strive for construction excellence and long-term asset value.

The global market for reinforcement wire and mesh products is experiencing robust growth, propelled by rapid urbanization in developing economies and the necessity of infrastructure upgrades in developed nations. According to a report by Grand View Research, the global concrete reinforcing fiber market size was valued at USD 1.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030, a testament to the continuous demand for enhanced concrete performance. This growth trajectory is significantly influenced by technological advancements in steel manufacturing, including the development of higher-strength alloys and more efficient welding techniques that improve the overall performance and reliability of reinforcement wire. Furthermore, the increasing adoption of prefabrication and modular construction methods demands consistent quality and precise dimensions from reinforcing materials, making the selection of a reputable supplier with advanced manufacturing capabilities crucial. The shift towards sustainable construction practices also impacts the reinforcement wire sector, with a growing focus on recycled content, reduced carbon footprints during production, and the extended service life of reinforced concrete structures, which inherently reduces the need for frequent repairs or replacements. As construction projects become more complex and performance expectations higher, the intrinsic value of meticulously engineered reinforcement wire and its derivatives, such as galvanized reinforcing mesh, becomes increasingly evident, safeguarding investments and ensuring the safety and functionality of built environments for decades to come.

The Anatomy of Reinforcement Wire: Materials and Manufacturing Excellence

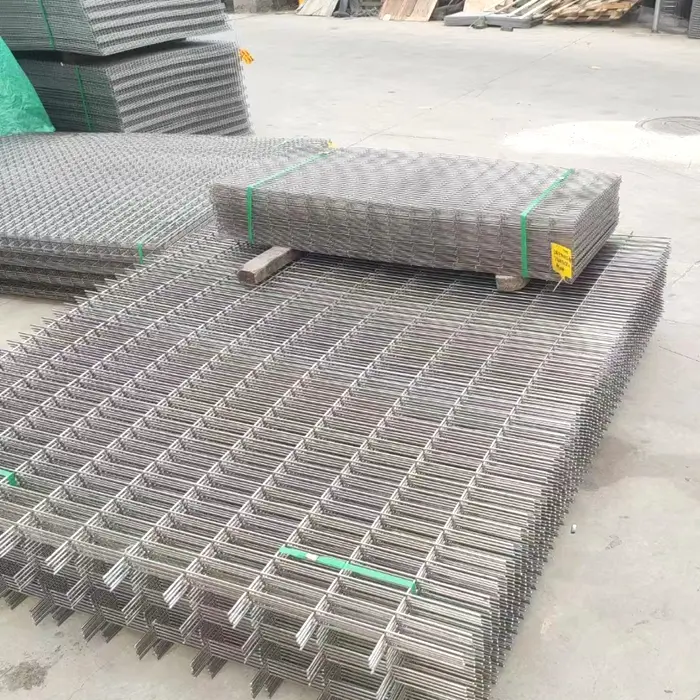

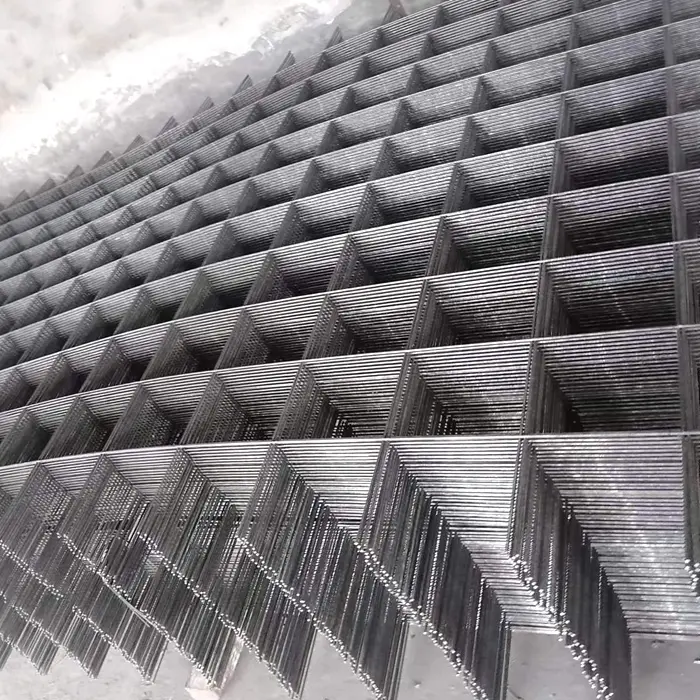

The manufacturing of high-quality reinforcement wire is a precise, multi-stage process that begins with the careful selection of raw materials. Typically, it involves high-carbon steel wire rods, known for their inherent strength and ductility. The primary manufacturing process is cold drawing, where the hot-rolled wire rod is pulled through a series of dies, progressively reducing its diameter and increasing its tensile strength and yield strength, an essential characteristic for structural applications. This cold working process refines the grain structure of the steel, enhancing its mechanical properties significantly. Following the drawing process, the individual wires undergo straightening and cutting to precise lengths, preparing them for the next critical stage: welding. For the production of reinforcement wire mesh, individual wires are resistance-welded at their intersections to form a grid pattern. This welding process is meticulously controlled to ensure strong, consistent welds that meet specified shear strength requirements, preventing slippage or separation under load. The quality control mechanisms throughout this entire sequence are paramount, involving continuous inline monitoring and rigorous post-production testing. These tests include tensile strength tests, yield strength tests, elongation tests, and weld shear strength tests, all performed in accordance with international standards such as ASTM A1064/A1064M (Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete), BS 4482/4483 (Specifications for Hard Drawn Mild Steel Wire/Steel Fabric for the Reinforcement of Concrete), and AS/NZS 4671 (Steel Reinforcing Materials).

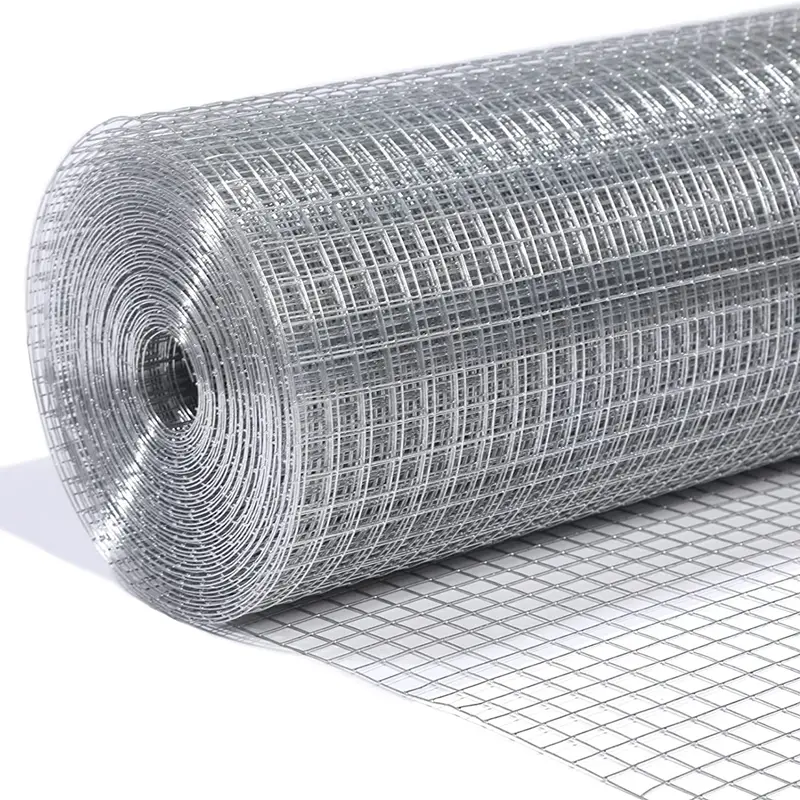

Beyond the fundamental manufacturing steps, specialized treatments enhance the performance and longevity of reinforcement wire. For instance, the production of galvanized reinforcing mesh involves hot-dip galvanizing the finished steel mesh. This process immerses the mesh in molten zinc, creating a metallurgically bonded coating that provides superior corrosion resistance. This is particularly crucial for structures exposed to harsh environments, such as coastal areas, chemical plants, or wastewater treatment facilities, where the presence of moisture, chlorides, or corrosive chemicals could accelerate steel degradation. The anti-corrosion properties significantly extend the service life of concrete structures, reducing maintenance costs and ensuring long-term structural integrity. In applications where reinforcement wire is used in industries like petrochemical, metallurgy, or water supply and drainage, its resistance to specific corrosive agents becomes a key advantage. The typical lifespan of concrete structures reinforced with high-quality, appropriately treated reinforcement wire can range from 50 to over 100 years, depending on environmental conditions and maintenance. Furthermore, the precise manufacturing of reinforcement wire ensures dimensional accuracy, which is crucial for efficient construction and minimizing material waste. The inherent strength and consistent quality of the manufactured reinforcement wire translate directly into robust and reliable concrete elements, contributing to energy efficiency by enabling thinner concrete sections without compromising structural performance, and inherently preventing premature structural failures due to material degradation.

Technical Specifications and Performance Metrics

The efficacy of reinforcement wire in structural applications is quantified by a series of critical technical parameters that define its performance under various loading conditions. Key among these are tensile strength, yield strength, and elongation. Tensile strength, measured in megapascals (MPa), indicates the maximum stress a wire can withstand before fracturing, while yield strength (also in MPa) denotes the point at which the wire begins to deform plastically. Elongation, expressed as a percentage, measures the wire's ductility – its ability to stretch before breaking, which is crucial for absorbing energy during seismic events or sudden impacts. For example, high-tensile reinforcement wire typically exhibits yield strengths ranging from 450 MPa to 550 MPa, with tensile strengths often exceeding 500 MPa, depending on the specific steel grade and standard adhered to (e.g., Grade 500E in Australia/New Zealand, where 'E' signifies earthquake resistance, or various grades under ASTM A1064). These specifications are not arbitrary; they are meticulously determined through extensive material science research and rigorous testing to ensure that the reinforcement wire provides the necessary structural integrity for various concrete applications, ranging from residential slabs to heavy-duty industrial foundations and bridge decks. The consistent adherence to these parameters across batches is critical for predictable structural behavior and compliance with building codes and engineering standards worldwide.

Furthermore, when considering reinforcement wire in its mesh form, such as galvanized reinforcing mesh, additional parameters come into play, including wire diameter, mesh size (pitch), and sheet dimensions. Wire diameters typically range from 2mm to 12mm, while mesh sizes can vary from 50x50mm to 200x200mm, dictated by the specific load-bearing requirements and crack control objectives of the concrete element. The uniformity of wire diameter and the precision of weld spacing are critical for ensuring even stress distribution throughout the concrete. The type of wire – plain or deformed – also impacts performance; deformed wires, with their ribbed or indented surfaces, provide superior bond strength with concrete, minimizing slippage and enhancing the composite action between steel and concrete. When incorporating galvanised reinforcing mesh or plain wire mesh, engineers also consider factors such as the amount of steel per unit area, often expressed as cross-sectional area per meter, to calculate the exact reinforcement required. The table below provides a typical overview of common specifications for steel reinforcement wire and mesh, highlighting the diversity and precision involved in meeting varied project demands while ensuring optimal structural performance, crack control, and long-term durability in concrete applications, crucial for preventing costly structural failures and ensuring public safety in the built environment.

| Parameter | Description | Typical Range/Value | Relevant Standard |

|---|---|---|---|

| Wire Diameter | Individual wire thickness | 2.0 mm - 12.0 mm | ASTM A1064, BS 4482, AS/NZS 4671 |

| Tensile Strength | Maximum stress before fracture | 500 MPa - 650 MPa | ASTM A1064, BS 4482, AS/NZS 4671 |

| Yield Strength | Stress at which plastic deformation begins | 450 MPa - 550 MPa | ASTM A1064, BS 4482, AS/NZS 4671 |

| Elongation | Ductility / % stretch before breaking | ≥ 5% (for ductile grades) | ASTM A1064, AS/NZS 4671 |

| Mesh Size (Pitch) | Spacing between wires in mesh | 50x50 mm - 200x200 mm | BS 4483, AS/NZS 4671 |

| Material Grade | Steel composition and properties | Plain Carbon Steel, High Tensile Steel (e.g., Grade 500E) | ASTM A1064, BS 4482, AS/NZS 4671 |

| Surface Finish | Protection against corrosion | Plain, Galvanized, Epoxy Coated | ASTM A767/A767M (Galvanized), ASTM A775/A775M (Epoxy) |

Diverse Applications and Sector-Specific Advantages

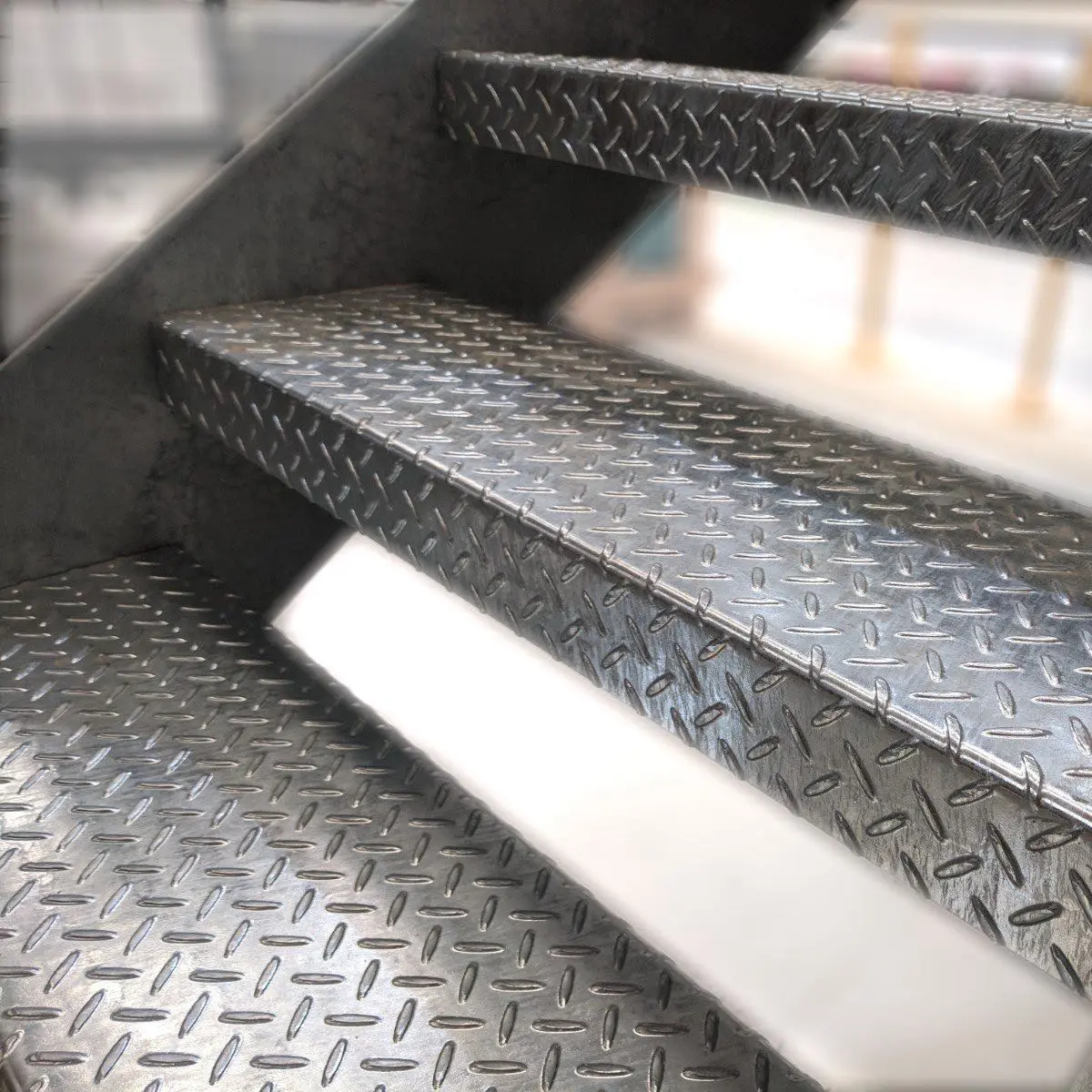

The versatility and robust performance of reinforcement wire underpin its widespread adoption across an expansive array of application scenarios in the construction and civil engineering sectors. Primarily, it is indispensable in concrete slab construction for residential, commercial, and industrial flooring, where it effectively controls thermal and shrinkage cracking, ensuring long-term surface integrity and reducing maintenance needs. Its use extends to foundations for buildings, providing the critical tensile strength required to resist differential settlement and uplift forces, thereby enhancing the overall stability and safety of structures. In precast concrete elements, such as wall panels, beams, and columns, reinforcement wire mesh enables efficient, high-volume production while maintaining stringent quality control, leading to faster construction times and reduced on-site labor. Beyond foundational and structural building components, reinforcement wire plays a vital role in extensive civil infrastructure projects. It is extensively utilized in the construction of roads, highways, and airport runways, where it improves the fatigue life of concrete pavements and minimizes the formation of cracks under heavy traffic loads and extreme temperature variations. For complex structures like bridges and tunnels, high-strength reinforcement wire is integral to resisting significant static and dynamic loads, ensuring the resilience and longevity of these critical transportation arteries.

The advantages derived from using high-quality reinforcement wire are multifaceted and significantly impact project outcomes. Firstly, it substantially enhances the structural integrity and durability of concrete by providing tensile reinforcement, preventing brittle failure and extending the service life of structures. This contributes to significant cost savings over time by reducing the need for costly repairs and premature replacement. Secondly, its ability to control cracking, particularly shrinkage and thermal cracking, leads to improved aesthetic quality and reduced permeability of concrete, which in turn enhances its resistance to chemical attack and freeze-thaw cycles. This makes galvanized reinforcing mesh particularly advantageous in aggressive environments, such as those found in the petrochemical or wastewater treatment industries, where traditional steel might succumb to corrosion. Thirdly, the use of prefabricated reinforcement wire mesh streamlines construction processes, reducing installation time and labor costs on-site, as it eliminates the need for individual bar tying. The precision of manufacturing also minimizes material waste and ensures consistent quality. In industries like water supply and drainage, reinforced concrete pipes, culverts, and reservoirs benefit immensely from the enhanced strength and crack resistance provided by reinforcement wire, ensuring leakage prevention and long-term operational reliability. These combined technical advantages make reinforcement wire an economically viable and structurally superior choice for a broad spectrum of engineering challenges, aligning with goals for sustainable and resilient infrastructure development.

Choosing Your Partner: Manufacturer Comparison and Customization

Selecting the right manufacturer for reinforcement wire is a strategic decision that profoundly impacts project timelines, budget adherence, and the long-term performance of your structures. A critical evaluation extends beyond mere price considerations to encompass manufacturing capabilities, adherence to international standards, quality control protocols, and customer service. Leading manufacturers distinguish themselves through state-of-the-art production facilities, employing advanced automated welding lines for steel reinforcement wire mesh that ensure consistent weld strength and precise dimensions. They rigorously implement ISO 9001 certified Quality Management Systems, providing complete traceability from raw material sourcing to the final product. For instance, a reputable supplier will offer detailed material test certificates (MTCs) for every batch, confirming compliance with specified mechanical properties such as tensile strength, yield strength, and chemical composition. When comparing manufacturers, it's essential to scrutinize their track record in delivering complex or large-scale projects, their capacity for high-volume orders, and their logistical efficiency in ensuring timely delivery to diverse geographic locations, which can significantly mitigate project delays. Furthermore, a commitment to continuous improvement and innovation, such as developing new corrosion-resistant coatings or higher-strength steel grades for reinforcement wire, signals a forward-thinking partner.

Beyond standard offerings, the ability to provide customized reinforcement wire solutions is a significant differentiator. Many projects have unique structural demands that necessitate bespoke mesh configurations, non-standard wire diameters, or specialized coatings like galvanised reinforcing mesh for enhanced durability in specific environments. A competent manufacturer will possess the engineering expertise and production flexibility to tailor wire spacing, sheet sizes, and even incorporate cut-outs or openings into the mesh design, optimizing material usage and reducing on-site fabrication efforts. This customized approach can lead to substantial cost savings by minimizing material waste and accelerating installation. For example, some projects may require specific bending or shaping of the reinforcement wire components prior to delivery, which a custom-oriented supplier can accommodate. Our company, with over two decades of experience in the wire mesh industry since 2002, prides itself on offering comprehensive customization services, backed by a deep understanding of B2B client needs and adherence to stringent quality controls. This commitment to tailored solutions, combined with competitive pricing and reliable delivery, positions us as a preferred partner for complex and demanding construction projects globally. The table below provides a concise comparison to illustrate key considerations when evaluating potential suppliers of reinforcement wire.

| Feature | Our Company | Competitor A (General) | Competitor B (Specialized) |

|---|---|---|---|

| Years in Business | 20+ Years (Since 2002) | 10-15 Years | 5-10 Years |

| Certifications | ISO 9001, ASTM, BS, AS/NZS Compliance | ISO 9001, Select Regional Standards | Basic QC, Local Standards |

| Customization Capability | Extensive (Dimensions, Coatings, Shapes) | Limited (Standard Sizes only) | Moderate (Some Custom Sizes) |

| Quality Control | Multi-stage, In-house Lab Testing, MTCs | Basic Inspection, Outsourced Testing | Spot Checks |

| Lead Time & Delivery | Optimized Logistics, Reliable, Global | Standard, Regional Focus | Variable, Local Only |

| Corrosion Resistance Options | Hot-dip Galvanized, Epoxy Coated, Stainless Steel Options | Limited Galvanized Options | Plain Steel Primarily |

Real-World Impact: Case Studies and Client Success

The tangible benefits of high-quality reinforcement wire are best illustrated through its application in diverse, real-world projects, showcasing its pivotal role in achieving structural resilience and operational efficiency. Consider a major highway expansion project in a seismically active region, where conventional reinforcing methods faced challenges with material consistency and rapid deployment. By adopting specialized reinforcement wire mesh with enhanced ductility (Grade 500E equivalent), the project significantly improved the crack control and seismic performance of concrete bridge decks and retaining walls. The use of prefabricated mesh panels allowed for faster installation, reducing traffic disruptions and overall project timelines by an estimated 15%, a direct result of the reduced on-site labor and simplified logistics. This efficiency gain was particularly critical in meeting strict governmental deadlines and minimizing public inconvenience. Furthermore, the uniform quality and precise dimensions of the manufactured reinforcement wire ensured that concrete pouring and finishing operations proceeded smoothly, reducing rework and material waste, which collectively led to substantial cost savings over the life cycle of the pavement structures. This example underscores how technical excellence in reinforcement wire manufacturing translates directly into project success metrics, providing verifiable evidence of its value proposition.

Another compelling application involves a large-scale industrial facility requiring a highly durable flooring system resistant to heavy machinery loads and chemical spills. Traditional plain steel reinforcement would have necessitated frequent maintenance due to corrosion risks. The solution involved utilizing galvanized reinforcing mesh specifically engineered for high load-bearing capacity and superior corrosion resistance. The zinc coating provided an impenetrable barrier against abrasive wear and chemical ingress, extending the floor's operational lifespan significantly and drastically reducing maintenance requirements over decades. Post-completion feedback from the client highlighted the floor's exceptional durability under continuous heavy traffic and its ability to withstand accidental chemical exposure without degradation. This case exemplified the long-term value delivered by selecting the appropriate type of reinforcement wire for specific environmental challenges. Our commitment extends beyond mere product supply; we offer comprehensive technical support, from initial design consultation to post-delivery assistance, ensuring optimal product integration and performance. Client testimonials consistently praise our responsiveness, the technical proficiency of our support teams, and the reliability of our products, affirming our role as a trusted partner in ensuring the success and longevity of critical infrastructure projects that rely on robust reinforcement wire solutions.

Frequently Asked Questions & Commitment to Trust

Understanding the common queries related to reinforcement wire is crucial for informed decision-making in B2B procurement. One frequent question pertains to the difference between plain reinforcement wire and galvanized reinforcing mesh. Plain reinforcement wire refers to uncoated steel wire, suitable for general concrete applications where corrosion is not a significant concern, or where the concrete cover provides sufficient protection. Galvanized reinforcing mesh, on the other hand, is steel mesh that has been hot-dip galvanized, receiving a protective zinc coating. This coating offers superior corrosion resistance, making it ideal for structures exposed to moisture, chlorides (e.g., de-icing salts, marine environments), or aggressive chemicals, significantly extending the concrete's lifespan and reducing maintenance costs. Another common inquiry focuses on the correct installation procedures for reinforcement wire mesh. Proper placement and concrete cover are paramount to ensure the mesh performs as intended; it must be positioned accurately within the concrete section to engage effectively in tension, typically lifted off the sub-base using chairs or spacers. Failure to maintain adequate concrete cover can lead to premature corrosion and structural failure. Our technical support team provides detailed guidance and documentation for optimal installation, drawing upon decades of practical experience.

Regarding delivery and logistics, clients often ask about lead times and order fulfillment for reinforcement wire. Our optimized supply chain and robust production capacity enable us to offer competitive lead times, typically ranging from 2-4 weeks for standard orders, with expedited options available for urgent projects. We manage complex logistics for global shipping, ensuring products arrive on schedule and in pristine condition, minimizing any potential for project delays. Quality assurance and product warranties are also frequently discussed. We stand by the quality of our reinforcement wire with a comprehensive product warranty, ensuring compliance with all specified technical parameters and industry standards like ASTM, BS, and AS/NZS. Each batch undergoes rigorous quality control checks and material testing, with certificates provided upon request, demonstrating our commitment to transparency and product integrity. Our dedicated customer support team is available to address any post-delivery concerns, provide technical assistance, or facilitate reorders, ensuring a seamless experience from inquiry to project completion. This unwavering commitment to product excellence, logistical efficiency, and client satisfaction forms the cornerstone of our trustworthiness in the global reinforcement wire market.

Conclusion: Forging Resilient Futures with Superior Reinforcement Wire

In conclusion, the strategic selection and implementation of high-quality reinforcement wire are paramount for engineering structures that are not only robust and durable but also sustainable and cost-effective over their entire lifecycle. From its meticulous manufacturing process involving cold drawing and precise welding to its critical role in enhancing the tensile strength and crack control of concrete, reinforcement wire stands as an unsung hero in modern construction. The technical advantages it offers—such as superior structural integrity, extended service life, and reduced maintenance needs, especially with specialized options like galvanized reinforcing mesh—directly translate into significant value for B2B stakeholders across diverse sectors including building construction, transportation infrastructure, and industrial facilities. Choosing a manufacturer with proven expertise, stringent quality control, and a capacity for customized solutions ensures that projects benefit from consistent product performance and reliable supply chains. Our extensive experience, adherence to global standards, and comprehensive customer support underscore our commitment to delivering reinforcement wire solutions that meet the most demanding project specifications and contribute to the long-term success and safety of built environments worldwide. As the demands on infrastructure continue to grow, the role of advanced reinforcement wire will only become more pronounced, underpinning the resilience and progress of global development.

References

- ASTM International. (2023). ASTM A1064/A1064M: Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete.

- British Standards Institution. (2007). BS 4483: Steel fabric for the reinforcement of concrete – Specification.

- Standards Australia/Standards New Zealand. (2009). AS/NZS 4671: Steel reinforcing materials.

- Grand View Research. (2023). Concrete Reinforcing Fiber Market Size, Share & Trends Analysis Report.