Elevating Infrastructure: The Prowess of galvanized reinforcing mesh in Modern Construction

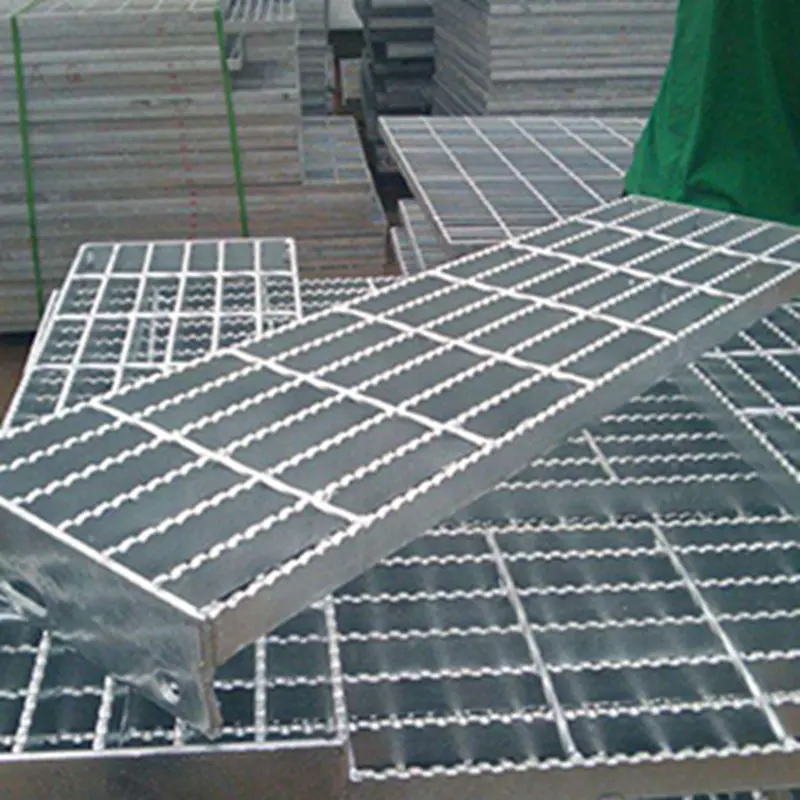

In the intricate landscape of contemporary infrastructure development, the selection of robust and durable materials is paramount. As industries increasingly demand longevity and resilience against environmental degradation, the significance of galvanized reinforcing mesh has surged. This specialized wire mesh, distinguished by its zinc coating, offers an unparalleled combination of structural integrity and superior corrosion resistance. From large-scale industrial projects to delicate architectural elements, its versatile applications address critical engineering challenges, mitigating the risks associated with material degradation over time. Understanding the inherent advantages and technical specifications of this material is crucial for engineers, procurement specialists, and project managers aiming for sustainable and cost-effective construction outcomes. Its ability to extend the service life of concrete structures, especially in harsh conditions, positions it as a cornerstone material for forward-thinking construction. The market is witnessing a steady upward trend in its adoption, driven by stringent safety standards and the economic imperative to minimize maintenance costs over a structure's lifecycle.

Beyond its fundamental strength, the advanced manufacturing processes involved in producing high-quality galvanized reinforcing mesh contribute significantly to its performance. The meticulous control over wire diameter, aperture size, and welding strength ensures that each sheet performs optimally under design loads. This attention to detail from raw material sourcing to final product inspection is what differentiates premium mesh from standard alternatives. Furthermore, its lightweight yet robust nature simplifies handling and installation on job sites, contributing to faster project completion times and reduced labor costs. The demand for materials that offer both enhanced performance and operational efficiencies underscores the integral role of galvanized mesh in modern construction paradigms, making it an indispensable component for resilient infrastructure projects worldwide.

The Meticulous Manufacturing Journey of Galvanized Reinforcing Mesh

The production of high-quality galvanized reinforcing mesh is a sophisticated multi-stage process, ensuring both structural integrity and exceptional corrosion resistance. It typically begins with the selection of high-grade steel wire, often low carbon or stainless steel, which undergoes rigorous quality checks for material composition and tensile strength. This raw wire is then straightened and cut to precise lengths, preparing it for the welding phase. Precision welding machinery, often utilizing advanced resistance welding techniques, fuses the longitudinal and transverse wires at their intersections, creating a rigid grid pattern. This critical step ensures uniform mesh aperture sizes and strong, unyielding weld points, which are paramount for its reinforcing capabilities in concrete. The adherence to standards such as ASTM A185/A185M or ISO 6935 is crucial at this stage, dictating the minimum yield strength and weld shear strength.

Following the welding, the mesh panels proceed to the galvanization stage. While pre-galvanized wire can be used, hot-dip galvanization after welding is often preferred for superior corrosion protection, especially for products like `6X6 Reinforcing Stainless Steel or Galvanized Steel Welded Wire Mesh`. In this process, the welded mesh is thoroughly cleaned to remove impurities, then fluxed to prepare the surface for zinc adhesion. It is then immersed in a bath of molten zinc at approximately 450°C (840°F). The metallurgical reaction between the steel and molten zinc forms a series of iron-zinc alloy layers, topped by a pure zinc outer layer. This robust coating provides cathodic protection, sacrificing itself to protect the underlying steel from rust even if the coating is scratched. The thickness of this zinc layer, typically measured in microns, directly correlates with the mesh's service life, especially in aggressive environments such as those found in petrochemical, metallurgical, and water supply/drainage industries. Post-galvanization, the mesh undergoes strict inspection, including adhesion tests, coating thickness measurements, and visual checks for uniformity, ensuring compliance with international standards like ASTM A123 or ISO 1461, guaranteeing a service life often exceeding 50 years under normal conditions. This meticulous process ensures the product delivers optimal performance, significantly contributing to the energy efficiency and anti-corrosion properties of reinforced structures.

Key Technical Specifications and Parameters

Understanding the technical specifications of galvanized reinforcing mesh is crucial for its effective application in diverse engineering projects. These parameters dictate the mesh's suitability for specific load-bearing requirements, environmental exposures, and construction methodologies. The product, `6X6 Reinforcing Stainless Steel or Galvanized Steel Welded Wire Mesh`, exemplifies the variety in material and configuration available to meet stringent project demands. The mesh size, defined by the spacing between wires, directly influences the concrete's ability to bond with the steel, ensuring uniform stress distribution and crack control. Wire diameter, on the other hand, determines the tensile strength and overall reinforcing capacity of the mesh. Larger diameters offer greater strength but also add more weight and potentially increase material costs.

The selection between galvanized steel and stainless steel for reinforcing mesh depends heavily on the corrosive environment and desired service life. While galvanized steel offers excellent cost-effectiveness and substantial corrosion protection for most applications, stainless steel is often preferred for extreme conditions such as marine environments, chemical processing plants, or areas with high chloride exposure, where its inherent corrosion resistance outperforms zinc coatings. Other critical parameters include panel dimensions, which impact transportation and installation efficiency, and tensile strength (measured in MPa), which verifies the material's ability to withstand pulling forces without fracturing. Compression strength, elongation, and the quality of welds are also subject to rigorous testing, ensuring that the mesh conforms to international standards such as ISO 9001 for quality management systems. Below is a representative table outlining typical parameters for galvanized reinforcing mesh, illustrating the precision involved in its manufacturing and application.

| Parameter | Typical Range / Value | Unit | Relevant Standard |

|---|---|---|---|

| Wire Diameter | 3.0 - 12.0 | mm | ASTM A1064, BS 4482 |

| Mesh Aperture (Square) | 50x50 to 200x200 | mm | ASTM A185, BS 4483 |

| Tensile Strength | 500 - 550 | MPa | ISO 6935-2 |

| Zinc Coating Thickness | 60 - 85 | microns | ISO 1461, ASTM A123 |

| Panel Width | 1.0 - 2.5 | m | Manufacturer Spec. |

| Panel Length | 2.0 - 6.0 | m | Manufacturer Spec. |

These specifications enable engineers to select the most appropriate type of galvanized reinforcing mesh for foundational slabs, retaining walls, precast concrete components, or even specialized uses where a `2x2 wire mesh` or `duck wire mesh` might be considered for specific non-structural or light-duty applications. The durability and structural integrity imparted by proper material selection ensure projects meet their design life and performance expectations with minimized long-term maintenance needs.

Versatile Applications and Unmatched Advantages

The adaptability of galvanized reinforcing mesh makes it an indispensable component across a multitude of industries and construction scenarios. Its primary role in reinforcing concrete structures enhances their tensile strength, preventing cracking and ensuring longevity, especially under dynamic loads or in environments prone to moisture and chemical exposure. In the infrastructure sector, it is extensively used in road construction for pavements and bridge decks, where it mitigates reflective cracking and improves load distribution. For building construction, it forms the backbone of concrete slabs for commercial and residential foundations, precast concrete walls, and floor systems, providing essential crack control and structural stability. The enhanced corrosion resistance afforded by galvanization is particularly beneficial in these applications, extending the service life of structures in challenging climates.

Beyond traditional concrete reinforcement, galvanised reinforcing mesh finds application in niche but critical areas. In mining, it serves as rockfall protection and ground support, offering a reliable barrier against geological hazards. Agricultural sectors utilize variations like `duck wire mesh` for fencing and enclosure purposes, benefiting from its durability and rust resistance against elements. Environmental projects, such as erosion control and slope stabilization, leverage its structural properties to hold soil and aggregate in place, preventing degradation. Its ease of handling and installation significantly reduces labor time and costs on site, contributing to overall project efficiency. Furthermore, in specialized construction, such as the creation of architectural concrete elements or the reinforcement of thin, curved structures, the flexibility and precise dimensions of welded mesh are invaluable. Its ability to maintain structural integrity in corrosive atmospheres, such as those found in wastewater treatment plants or coastal developments, underscores its superior performance over ungalvanized alternatives. This widespread utility, coupled with its proven longevity, positions it as a preferred choice for engineers seeking reliable, long-term solutions.

Customized Solutions and Manufacturer Expertise

Selecting a manufacturer for galvanized reinforcing mesh goes beyond mere product specifications; it involves assessing their capability to deliver customized solutions, adherence to quality standards, and comprehensive customer support. Leading manufacturers, like our enterprise, specialize in providing bespoke mesh configurations, including specific wire gauges, mesh opening sizes (such as precise `2x2 wire mesh` configurations), and panel dimensions to meet unique project demands. This customization extends to material selection, offering both standard hot-dip galvanized steel and high-grade stainless steel options for the `6X6 Reinforcing Stainless Steel or Galvanized Steel Welded Wire Mesh` product, ensuring optimal performance in various environmental conditions. Our commitment to ISO 9001 and ISO 14001 certifications guarantees consistent product quality and environmentally responsible manufacturing practices, instilling confidence in our B2B partners. We pride ourselves on a proven track record, having supplied our mesh to critical infrastructure projects globally for over two decades, reflected in numerous positive client testimonials and successful case studies across diverse industries.

Our technical team collaborates closely with clients from the initial design phase through to project completion, offering expert consultation on material selection, structural calculations, and installation best practices. This ensures that the chosen galvanised reinforcing mesh solution is not only technically sound but also economically viable. For instance, in a recent coastal defense project, our ability to provide large, custom-sized galvanized panels significantly reduced on-site welding and improved installation efficiency, leading to substantial cost savings for the client. Our average lead time for standard orders is 10-15 business days, with expedited options available for urgent requirements, backed by a comprehensive five-year material warranty. This holistic approach, combining product excellence with unparalleled technical support and flexible supply chain management, establishes us as a trusted partner in the supply of high-performance reinforcing solutions, catering to the evolving needs of the construction and industrial sectors.

Ensuring Trust and Authority: FAQs and Support

Frequently Asked Questions (FAQs)

-

Q: What is the typical lifespan of galvanized reinforcing mesh?

A: Under normal environmental conditions and proper concrete cover, galvanized reinforcing mesh can have a service life exceeding 50 years. In highly corrosive environments, its lifespan is significantly longer than ungalvanized steel, often reaching 20-30 years where ungalvanized steel might fail in less than a decade. -

Q: How does hot-dip galvanization compare to other protective coatings for reinforcing mesh?

A: Hot-dip galvanization provides a metallurgical bond between zinc and steel, offering superior abrasion resistance and cathodic protection compared to paint or epoxy coatings. It forms a uniform barrier, even on complex shapes, which is critical for the long-term integrity of galvanised reinforcing mesh. -

Q: Can your mesh products be customized for specific project requirements?

A: Absolutely. We specialize in custom manufacturing of `6X6 Reinforcing Stainless Steel or Galvanized Steel Welded Wire Mesh`, allowing for variations in wire diameter, mesh aperture (including `2x2 wire mesh` configurations), panel dimensions, and material grade (galvanized or stainless steel) to precisely match your project's engineering specifications.

Delivery & Warranty Information

Our commitment to client satisfaction extends to transparent delivery protocols and robust warranty assurances. Standard orders for galvanized reinforcing mesh typically have a lead time of 10-15 business days from order confirmation, depending on volume and customization complexity. For urgent projects, expedited manufacturing and shipping options are available upon request, with logistics support to ensure timely delivery worldwide. Each batch of our mesh undergoes stringent pre-shipment quality control checks, including adherence to ISO standards, and is carefully packaged to prevent damage during transit. We provide comprehensive documentation, including material test certificates and compliance reports, with every shipment.

We stand by the quality and durability of our products, offering a standard five-year limited warranty on all our galvanised reinforcing mesh against manufacturing defects and premature corrosion under normal use conditions. Our dedicated customer support team is available to assist with any post-purchase inquiries, technical guidance, or warranty claims, ensuring a seamless experience from order placement to product utilization. Our long-standing relationships with global partners, including contractors, engineering firms, and government agencies, are a testament to our unwavering commitment to product excellence and reliable service.

References

- American Society for Testing and Materials (ASTM). (2020). ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. West Conshohocken, PA: ASTM International.

- International Organization for Standardization (ISO). (2015). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods. Geneva, Switzerland: ISO.

- British Standards Institution (BSI). (2007). BS 4483: Steel fabric for the reinforcement of concrete — Specification. London, UK: BSI Standards Limited.

- European Committee for Standardization (CEN). (2008). EN 10244-2: Steel wire and wire products — Non-ferrous metallic coatings on steel wire — Part 2: Zinc or zinc alloy coatings. Brussels, Belgium: CEN.