Advancing Industrial Infrastructure with Galvanized Steel Grates: A Comprehensive Insight

In the demanding landscape of modern industrial and civil engineering, the choice of robust and durable materials is paramount. Among the most critical components for safety, drainage, and structural integrity are industrial grates, with the galvanized steel grate standing out as an indispensable solution. This highly resilient material, renowned for its exceptional corrosion resistance and load-bearing capacity, underpins the operational safety and longevity of countless facilities worldwide. The market for these essential products is currently experiencing significant evolution, driven by an increasing emphasis on environmental sustainability, enhanced safety standards, and the imperative for customized solutions tailored to specific project requirements. Emerging trends include the adoption of advanced fabrication techniques to improve precision and efficiency, the development of specialized coatings for extreme environments, and a growing demand for products like steel grate steps and steel grate sheets that offer superior anti-slip properties and ease of installation. Industries are increasingly seeking solutions that not only meet stringent performance criteria but also contribute to lower lifecycle costs through reduced maintenance and extended service life. This includes a heightened focus on products such as the Step grating serrated non-slip galvanized steel grate, which integrates superior slip resistance with the inherent durability of hot-dip galvanized steel, making it ideal for high-traffic or wet environments. Understanding the intricate details of manufacturing, technical specifications, and application advantages is crucial for B2B decision-makers aiming to optimize infrastructure performance and ensure long-term operational excellence, providing a robust foundation for critical industrial and public works projects in challenging conditions.

The Meticulous Manufacturing Process of Galvanized Steel Grates

The production of a high-quality galvanized steel grate involves a series of precision-engineered steps designed to ensure structural integrity, durability, and a prolonged service life. The journey begins with the selection of premium-grade steel, typically low-carbon steel, chosen for its excellent weldability and mechanical properties. Raw steel is precisely cut into load-bearing bars and cross rods using advanced shearing or laser cutting techniques, ensuring uniform dimensions and minimal material waste. These components then undergo a meticulous assembly phase, where the load-bearing bars are arranged parallel to each other, and the cross rods are resistance-welded or pressure-locked into place. Resistance welding, a common technique, fuses the two components under high pressure and heat, creating a robust and monolithic structure that can withstand significant loads and vibrations. Following fabrication, the grates are thoroughly cleaned to remove any scale, rust, or impurities that could impede the galvanization process. This often involves degreasing, pickling in acid baths, and rinsing. The critical step is hot-dip galvanization, where the fabricated steel grate is fully immersed in a bath of molten zinc at temperatures around 450°C (840°F). During this immersion, a metallurgical bond forms between the steel and the zinc, creating a highly durable and corrosion-resistant coating that adheres uniformly to all surfaces, including edges and internal areas. This zinc layer acts as both a barrier protection and cathodic protection, effectively shielding the underlying steel from rust and abrasion. Quality control is paramount throughout the entire process, with adherence to international standards such as ISO 9001 for quality management systems and ASTM A123/A123M for the zinc coating specifications. Each batch undergoes rigorous inspection for weld integrity, dimensional accuracy, flatness, and coating thickness, ensuring that the final product, including specialized variations like steel grate steps, meets stringent performance benchmarks. The resulting galvanized steel grate boasts an impressive service life, often exceeding 50 years in typical atmospheric conditions, minimizing the need for frequent replacement and contributing to significant long-term cost savings by reducing maintenance cycles and associated labor costs.

Technical Specifications and Performance Metrics for Galvanized Steel Grating

The performance and suitability of a galvanized steel grate for specific applications are defined by a range of critical technical parameters. Understanding these specifications is essential for engineers and procurement specialists to ensure optimal structural integrity and safety. Key parameters include the dimensions of the load-bearing bars (depth and thickness), the spacing between these bars (pitch), and the spacing of the cross rods. Common load-bearing bar depths range from 20mm to 100mm, with thicknesses typically between 3mm and 10mm, directly influencing the grate's load-bearing capacity. Standard mesh sizes, such as 30x100mm, 40x100mm, or 30x50mm, dictate the opening size and thus the ability to allow fluid or air passage while preventing unwanted debris from falling through. The zinc coating thickness, typically measured in micrometers (µm), is governed by standards like ISO 1461 or ASTM A123/A123M, with common values ranging from 65µm to over 85µm for structural steel, directly impacting the corrosion protection and projected service life. The material grade of the base steel (e.g., Q235, S235JR) also contributes to the mechanical properties such as yield strength and tensile strength, crucial for structural calculations. For specialized products like steel grate steps, additional parameters include nosing type (e.g., checkered plate nosing, serrated bar nosing) and side plate designs, which enhance safety and ease of installation. Furthermore, the surface type—plain or serrated—is a vital consideration; serrated surfaces, characteristic of the Step grating serrated non-slip galvanized steel grate, significantly increase the coefficient of friction, providing superior slip resistance in wet, oily, or icy conditions, which is critical for industrial walkways and platforms. These precise specifications allow for tailoring solutions to meet diverse industrial demands, from heavy-duty vehicle traffic areas to light-duty pedestrian walkways, ensuring compliance with relevant safety standards such as ANSI/NAAMM MBG 531 for metal bar grating.

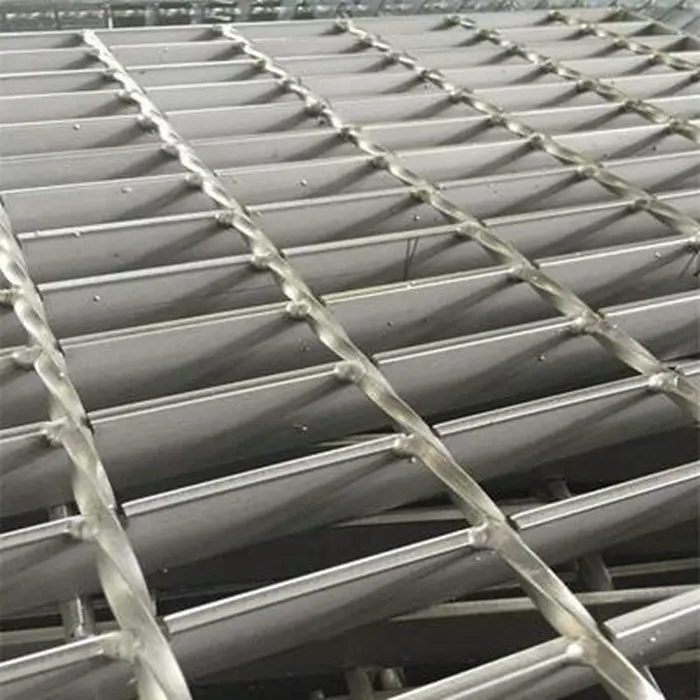

Fig 1: Typical Galvanized Steel Grate in industrial application.

Common Galvanized Steel Grate Specifications

| Parameter | Description | Typical Range/Value | Relevant Standard |

|---|---|---|---|

| Load Bar Depth | Height of the bearing bar, determines load capacity. | 20mm - 100mm | ANSI/NAAMM MBG 531 |

| Load Bar Thickness | Width of the bearing bar. | 3mm - 10mm | ANSI/NAAMM MBG 531 |

| Load Bar Pitch | Center-to-center spacing of bearing bars. | 30mm, 40mm, 60mm | ANSI/NAAMM MBG 531 |

| Cross Rod Pitch | Center-to-center spacing of cross rods. | 50mm, 100mm | ANSI/NAAMM MBG 531 |

| Zinc Coating Thickness | Minimum average zinc coating applied via hot-dip galvanization. | ≥ 65 µm (for | ISO 1461, ASTM A123/A123M |

| Surface Type | Plain or serrated for slip resistance. | Plain, Serrated | Industry Standard |

This table highlights the foundational specifications that define the structural and performance characteristics of a galvanized steel grate. The ability to specify precise dimensions and coating parameters allows for the creation of tailored solutions that can meet diverse loading requirements, environmental challenges, and safety mandates across various industrial environments. The synergy between material science and precision engineering ensures that each grate delivers optimal performance and long-term value, making them a cornerstone of modern industrial design and safety protocols. These detailed technical parameters not only guide the selection process but also assure compliance with stringent industry regulations, thereby enhancing overall project reliability and minimizing potential risks during operation.

Diverse Applications and Unparalleled Technical Advantages

The inherent strength, durability, and corrosion resistance of galvanized steel grate make it an indispensable material across an exceptionally broad spectrum of industrial and commercial applications. In the petrochemical and oil & gas sectors, these grates are crucial for platforms, walkways, and trench covers, providing safe and stable access in environments exposed to corrosive chemicals and extreme weather. Power generation plants, including thermal and nuclear facilities, rely on these grates for boiler access platforms, turbine halls, and cable trench covers, where their high load capacity and fire resistance are paramount. The metallurgy industry utilizes galvanized steel grate in smelting operations, rolling mills, and casting facilities due to its ability to withstand high temperatures and abrasive conditions. In the wastewater treatment and municipal drainage systems, they serve as robust channel covers, providing efficient liquid drainage while preventing debris accumulation and ensuring public safety. Shipbuilding and offshore platforms extensively use steel grate sheets and steel grate steps for decks, gangways, and engine room platforms, benefiting from their marine-grade corrosion protection and anti-slip properties, particularly relevant for the Step grating serrated non-slip galvanized steel grate in wet environments. Beyond heavy industry, these grates are increasingly specified in architectural designs for facades, sunscreens, and mezzanines due to their aesthetic appeal and open mesh structure, which allows for light and air penetration, contributing to energy efficiency by reducing the need for artificial lighting and improving ventilation. Their technical advantages are multifaceted: superior corrosion protection afforded by the hot-dip galvanization process ensures longevity and reduces maintenance costs significantly compared to painted steel. High strength-to-weight ratio allows for lighter structures without compromising load capacity. Excellent drainage capabilities prevent water accumulation, mitigating slip hazards and structural damage from standing water. Moreover, the open mesh design promotes ventilation, dissipating heat and allowing for natural light, which are critical for operational efficiency and safety in enclosed industrial settings. An exemplary application case involves a major chemical processing plant upgrading its entire network of elevated walkways and service platforms. By replacing existing carbon steel grating with hot-dip galvanized steel grate, the plant reported a reduction in yearly maintenance expenditure by over 40% and a significant improvement in worker safety due to the enhanced slip resistance and long-term structural integrity in a highly corrosive atmosphere, demonstrating tangible benefits.

Strategic Partner Selection and Tailored Galvanized Steel Grate Solutions

Selecting the right manufacturer for galvanized steel grate products is a critical decision that impacts project timelines, budget adherence, and long-term operational reliability. A reputable manufacturer differentiates itself through adherence to rigorous quality standards, comprehensive engineering support, and robust customization capabilities. Key factors to consider include the manufacturer's experience in the industry, their certifications (e.g., ISO 9001, CE marking), the quality of their raw materials, and their hot-dip galvanization process, which should comply with international standards like ISO 1461. Furthermore, a strong track record of successful project delivery and positive client testimonials provides invaluable insight into their reliability. Customization is often a pivotal requirement in complex industrial projects, and a versatile manufacturer should be able to offer bespoke solutions for galvanized steel grate, including non-standard dimensions, unique cut-outs for pipes or columns, specialized banding, and specific surface finishes. For instance, the demand for custom steel grate steps with precise rise and run configurations or large steel grate sheet panels for expansive floor areas is increasingly common. This flexibility ensures that the grating perfectly integrates into existing or new infrastructure, minimizing on-site modifications and installation costs.

Key Manufacturer Comparison Factors

| Feature | Tier 1 Manufacturer | Standard Manufacturer |

|---|---|---|

| Certifications | ISO 9001, CE, ASTM A123, ISO 1461 | Basic ISO 9001 |

| Customization Capability | Highly flexible: custom dimensions, cut-outs, shapes, finishes. | Limited: standard sizes, basic cut-outs. |

| Engineering Support | Full design, load calculation, drawing services. | Basic technical data sheets. |

| Warranty & After-Sales | Extensive product warranty, dedicated support. | Standard product warranty. |

| Delivery Lead Time | Optimized and flexible based on project scale. | Standard, less flexible. |

Fig 2: Custom-fabricated Galvanized Steel Grate for specific industrial requirements.

The ability to provide highly customized solutions, such as the Step grating serrated non-slip galvanized steel grate with bespoke dimensions for a complex access stairwell, underscores a manufacturer's commitment to meeting unique client needs. This personalized approach not only guarantees perfect fit and function but also streamlines installation processes and minimizes potential on-site adjustments, leading to overall project efficiency and cost-effectiveness. By partnering with a manufacturer that combines technical prowess with a deep understanding of industry-specific challenges, businesses can secure galvanized steel grate solutions that are truly fit for purpose and engineered for longevity, aligning with both immediate project needs and long-term operational strategies for diverse industrial environments.

Ensuring Trust and Reliability: Quality Assurance, Delivery, and Support

In the B2B landscape, particularly for critical infrastructure components like the galvanized steel grate, trust is built on a foundation of verifiable quality, predictable delivery, and unwavering customer support. Leading manufacturers implement comprehensive quality management systems, often certified to ISO 9001:2015, which covers every stage from raw material procurement to final inspection and dispatch. This includes rigorous material testing, dimensional checks during fabrication, and post-galvanization inspections for coating thickness and adhesion, typically performed in accordance with ISO 1461 or ASTM A123/A123M standards. Certificates of Conformance (CoC) and Material Test Reports (MTRs) are standard offerings, providing full traceability and assurance of product integrity. Furthermore, understanding and meeting project deadlines is paramount; therefore, reliable manufacturers provide clear, transparent delivery schedules and possess efficient logistics networks to ensure timely dispatch and arrival, whether for standard steel grate sheet panels or custom-fabricated steel grate steps. Our commitment extends to providing robust warranty commitments, typically covering defects in material and workmanship for a substantial period, underscoring confidence in the product's longevity and performance. Client support is proactive and responsive, offering technical assistance, installation guidance, and swift resolution of any post-delivery inquiries. This holistic approach to quality assurance and customer service minimizes project risks and optimizes the total cost of ownership for our clients. A dedicated FAQ section helps address common queries quickly, covering topics such as load capacities, installation methods, maintenance requirements, and the specific advantages of serrated non-slip surfaces for our Step grating serrated non-slip galvanized steel grate product. This comprehensive framework of support and quality control reinforces the trustworthiness of the product and the partnership.

Frequently Asked Questions (FAQs)

-

Q: What is the typical lifespan of a galvanized steel grate?

A: In most atmospheric conditions, a hot-dip galvanized steel grate can last 50 years or more. In more corrosive industrial environments, its lifespan might be reduced but still far exceeds that of ungalvanized steel, offering superior long-term cost-effectiveness.

-

Q: How does serrated grating enhance safety?

A: Serrated surfaces on a galvanized steel grate significantly increase the coefficient of friction, providing superior slip resistance, especially in areas prone to moisture, oil, grease, or ice, thereby substantially reducing the risk of falls and improving workplace safety.

-

Q: Can galvanized steel grates be custom-fabricated?

A: Absolutely. Reputable manufacturers offer extensive customization options, including specific dimensions, unique cut-outs, special banding, and varied bar/cross rod spacing to perfectly fit complex project requirements, ensuring seamless integration and optimal performance.

Our commitment to clear communication, stringent quality control, and comprehensive after-sales support ensures that clients receive not just a product, but a reliable solution backed by expertise and dedication. This unwavering dedication to client satisfaction and product excellence underpins every interaction and delivery, solidifying our position as a trusted partner in industrial infrastructure.

Conclusion: The Enduring Value of Galvanized Steel Grates

The galvanized steel grate remains a cornerstone of robust industrial infrastructure, a testament to its enduring blend of strength, durability, and corrosion resistance. Its versatile applications, spanning from heavy industrial platforms in petrochemical facilities to aesthetic architectural elements, underscore its critical role in ensuring safety, functionality, and longevity across diverse environments. As industries continue to evolve, driven by demands for greater efficiency, enhanced safety protocols, and sustainable material choices, the appeal of hot-dip galvanized steel products will only grow. Innovations in manufacturing processes and a deeper understanding of material science will further refine these products, leading to even more specialized and high-performance solutions, such as the Step grating serrated non-slip galvanized steel grate, designed to meet the most challenging operational demands. For B2B decision-makers, investing in high-quality galvanized steel grate solutions from a reliable manufacturer represents a strategic commitment to operational excellence, reduced lifecycle costs, and the sustained safety of personnel and assets. By prioritizing products that adhere to rigorous international standards and are backed by comprehensive engineering and support, businesses can ensure their infrastructure remains resilient, compliant, and performs optimally for decades to come, providing a solid foundation for industrial advancement and sustained operational efficiency in any demanding setting.

References

- International Organization for Standardization (ISO) 1461: Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- ASTM International A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- National Association of Architectural Metal Manufacturers (NAAMM) MBG 531: Metal Bar Grating Manual.

- NACE International (formerly National Association of Corrosion Engineers) Standards and Publications on Corrosion Prevention.

Note: The information provided in this article is for general informational purposes only and does not constitute professional advice. Specific project requirements should always be evaluated by qualified engineers.