Unveiling the Versatility and Engineering Prowess of Steel Grating in Modern Infrastructure

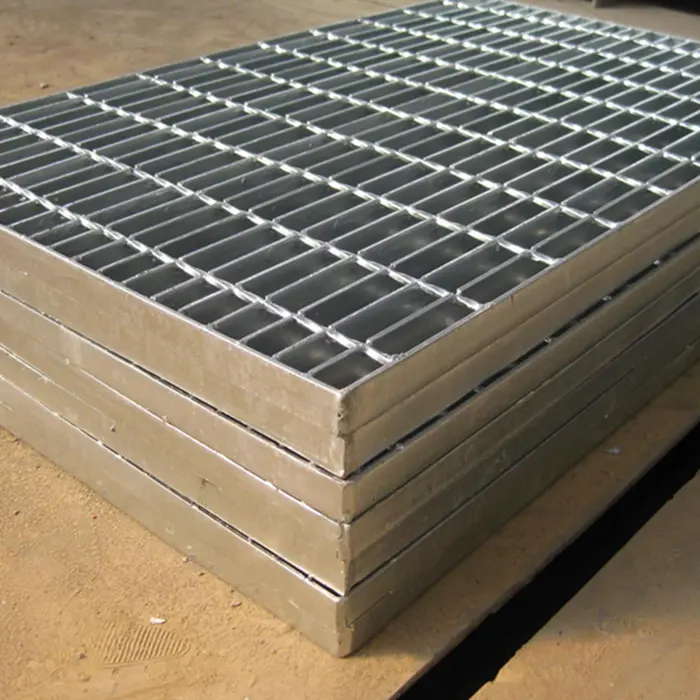

In the realm of contemporary industrial and architectural design, the foundational role of high-performance materials cannot be overstated. Among these, steel grating stands out as an indispensable component, offering unparalleled strength, durability, and versatility across a myriad of applications. This engineered product, comprising a series of bearing bars and cross bars, welded or locked together, provides robust solutions for flooring, platforms, walkways, drainage covers, and ventilation grates. Its open structure facilitates light and air penetration, minimizes debris accumulation, and offers excellent slip resistance, making it ideal for environments demanding stringent safety and operational efficiency. Current industry trends emphasize sustainable manufacturing practices, advanced material composites for enhanced corrosion resistance, and precision engineering for bespoke applications. The increasing demand for solutions like heavy duty steel grating in sectors such as energy, transportation, and chemical processing underscores a global shift towards infrastructure that prioritizes longevity and resilience in challenging conditions. Understanding the technical specifications and application nuances of this material is critical for project success, ensuring optimal performance and compliance with international standards.

The evolution of steel grating has been driven by the increasing complexity of industrial demands. From simple walkways to sophisticated architectural elements, its adaptability is unmatched. Innovations in surface treatments, such as hot-dip galvanization and specialized coatings, have significantly extended its service life, even in highly corrosive environments. Furthermore, the development of diverse material grades, including various types of stainless steel and carbon steel, allows for precise material selection based on specific load-bearing requirements, environmental exposure, and aesthetic considerations. This adaptability extends to modular designs and custom fabrication, enabling architects and engineers to seamlessly integrate steel grating into complex structures. The focus on lightweight yet robust designs is also paramount, contributing to reduced construction costs and improved logistical efficiency. As industries continue to seek cost-effective, durable, and environmentally conscious solutions, the role of high-quality steel grating remains central to achieving these objectives, providing a foundation for safer, more efficient, and sustainable industrial and commercial spaces globally.

The Meticulous Manufacturing Process of Premium Steel Grating

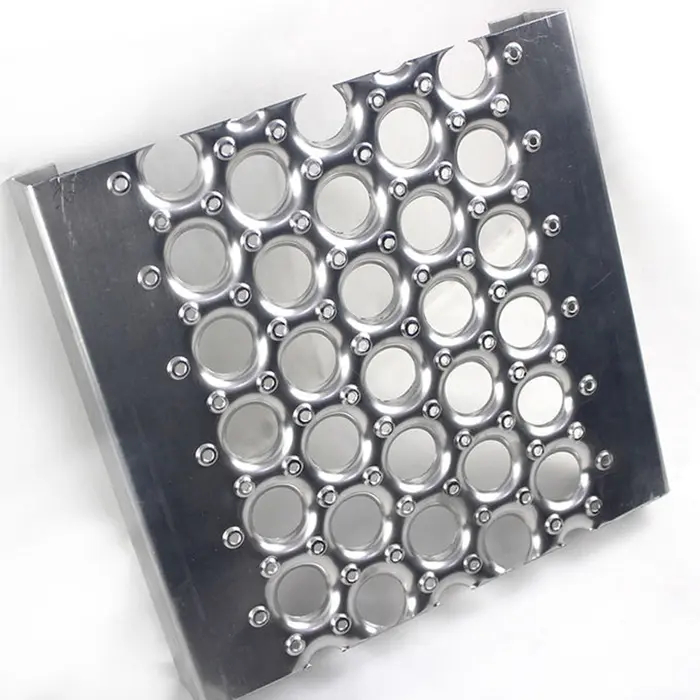

The production of high-quality steel grating is a sophisticated industrial process that demands precision engineering and rigorous quality control at every stage. It typically begins with the selection of premium raw materials, most commonly low carbon steel, stainless steel (e.g., 304, 316), or aluminum alloys, chosen for their specific strength-to-weight ratios and corrosion resistance properties. For applications requiring exceptional durability, such as those involving heavy duty steel grating, high-grade structural steels are preferred. The initial step involves cutting the bearing bars and cross bars to precise dimensions using advanced machinery like CNC laser cutters or high-speed band saws, ensuring dimensional accuracy crucial for structural integrity. Following cutting, the bearing bars are notched or slotted to prepare them for receiving the cross bars. The primary manufacturing technique for bonding these components is pressure welding (also known as resistance welding or forge welding), where immense pressure and electric current fuse the bars without the need for filler material, creating an incredibly strong and uniform bond. This method is especially vital for producing grating with consistent load-bearing capabilities.

After the welding process, the larger panels of steel grating undergo further processing, including trimming, banding (welding a flat bar to the edges for enhanced strength and aesthetics), and fabricating any necessary cutouts or shapes for specific installations. Surface treatment is a critical stage, profoundly influencing the grating's longevity and performance, particularly in harsh environments. Common treatments include hot-dip galvanization, which provides a robust zinc coating for superior corrosion resistance, suitable for industrial and outdoor applications. Other options include painting, powder coating for specific colors or enhanced durability, and electropolishing for stainless steel grating to achieve a smooth, hygienic finish. Throughout the entire manufacturing cycle, stringent quality control measures are implemented. Products are inspected according to international standards such as ISO 9001, ANSI/NAAMM MBG 531-09 (Metal Bar Grating Manual), and ASTM standards, which cover material specifications, load deflection tests, and dimensional tolerances. These rigorous checks ensure that each panel of steel grating meets the specified structural integrity, safety requirements, and an impressive service life typically ranging from 20 to 50 years, depending on the material and environmental conditions. This meticulous approach guarantees that the final product can withstand the demanding conditions of petrochemical, metallurgical, and water treatment industries, among others.

Technical Parameters and Cost Considerations for Steel Grating Solutions

Selecting the appropriate steel grating involves a detailed analysis of various technical parameters to ensure it meets the specific load-bearing requirements, environmental conditions, and operational demands of a project. Key parameters include the dimensions of the bearing bars (height and thickness), the spacing between bearing bars (pitch), and the spacing of the cross bars. For instance, a wider bearing bar and closer spacing provide greater load capacity, making it suitable for heavy duty steel grating applications. Material grade (e.g., Q235 carbon steel, 304/316 stainless steel) significantly impacts corrosion resistance, strength, and overall longevity. The surface finish, such as hot-dip galvanized, painted, or mill finish, also plays a crucial role in determining its suitability for specific environments and its maintenance requirements. Understanding these specifications is paramount for engineers and procurement specialists to ensure optimal performance and safety. The table below provides a general overview of typical parameters for various steel grating types.

The heavy duty steel grating price is influenced by several factors, including the material type, bar dimensions, spacing, surface treatment, and overall panel size and quantity. Stainless steel grating, particularly grades like 316L, will inherently have a higher cost than carbon steel due to material expense and specialized manufacturing processes. However, its superior corrosion resistance translates into lower long-term maintenance costs and extended service life in aggressive environments, often making it a more economical choice over the product's lifespan. Custom fabrication, complex cutouts, and unique banding requirements also contribute to the final price. Larger projects benefit from economies of scale, leading to more competitive unit pricing. When evaluating the heavy duty steel grating price, it is crucial to consider not just the initial procurement cost but also installation expenses, anticipated maintenance, and the product's expected durability, especially in critical infrastructure applications where failure can have significant financial and safety implications. Investing in high-quality steel grating from a reputable manufacturer ensures adherence to performance specifications and offers long-term value.

Diverse Applications and Strategic Advantages of Steel Grating

The robust design and functional attributes of steel grating make it an indispensable material across a vast spectrum of industries and applications. Its primary utility lies in creating safe, durable, and highly functional surfaces where strength, ventilation, and light penetration are critical. In the petrochemical sector, steel grating is extensively used for elevated walkways, platforms, and stair treads around processing units, offering excellent resistance to corrosive fumes and heavy loads while facilitating airflow and preventing hazardous gas accumulation. Similarly, in metallurgy and power generation plants, it forms the backbone of operating floors, boiler platforms, and utility trenches, capable of withstanding extreme temperatures and heavy machinery. The water treatment and municipal drainage industries rely on steel grating for trench covers, culvert grates, and pump station flooring, where its open design efficiently manages liquid flow and prevents debris buildup, significantly contributing to flood control and hygiene. Furthermore, its application extends to architectural facades, bridge decks, and even ship decks, demonstrating its versatility beyond purely industrial functions.

The technical advantages of steel grating are numerous and directly contribute to its widespread adoption. Foremost among these is its exceptional strength-to-weight ratio, which allows for robust load-bearing capabilities without imposing excessive dead loads on the supporting structure. This translates into significant material savings and easier installation. Its open design ensures superior ventilation, crucial for dissipating heat in industrial settings and preventing the accumulation of hazardous gases. Concurrently, it allows for effective light transmission, reducing the need for artificial lighting and contributing to energy savings, particularly in multi-story industrial facilities. Slip resistance, often enhanced by serrated bearing bars or specialized coatings, is a key safety feature, especially in wet or oily environments. Furthermore, its inherent durability, especially when fortified with hot-dip galvanization or made from stainless steel, provides excellent corrosion resistance, dramatically extending its service life and reducing maintenance costs. This longevity and minimal upkeep make it a highly cost-effective solution over its operational lifespan, distinguishing it from less durable alternatives. For critical applications, the anti-corrosion properties of specific materials like stainless steel plate steel grating ensure long-term structural integrity and operational safety, embodying a proactive approach to asset management and environmental protection.

Manufacturer Comparison and Tailored Steel Grating Solutions

The process of selecting a steel grating manufacturer is a critical decision that profoundly impacts project timelines, structural integrity, and long-term cost-efficiency. Key factors for comparison extend beyond just the heavy duty steel grating price to encompass material quality, adherence to international manufacturing standards, and the breadth of customization capabilities. Reputable manufacturers distinguish themselves through certified quality management systems (e.g., ISO 9001), consistent material sourcing from verified suppliers, and advanced production technologies that ensure precise dimensional accuracy and superior weld integrity. Furthermore, a manufacturer's experience in handling diverse industrial projects provides invaluable insight into specific application challenges, such as extreme loads or highly corrosive environments. This experience translates into the ability to recommend optimal material grades, bar configurations, and surface treatments that align with the operational demands and regulatory compliance of a given project. Evaluating their track record, client testimonials, and technical support capabilities is essential for establishing a reliable partnership that ensures the delivery of high-performance grating solutions.

Customization is a cornerstone of modern steel grating procurement, recognizing that off-the-shelf solutions rarely fit the precise requirements of complex industrial or architectural designs. Leading manufacturers offer comprehensive customization services, allowing clients to specify every aspect of the grating, from unique panel sizes and shapes to specific load-bearing capacities and surface finishes. This includes tailoring bearing bar height and thickness for bespoke load requirements, adjusting bar spacing for particular pedestrian or vehicle traffic, and integrating cutouts for pipes, columns, or other structural elements. For specialized applications requiring exceptional resistance to chemicals or extreme temperatures, manufacturers can fabricate steel grating from high-grade stainless steel or provide specialized anti-slip coatings. Such tailored solutions ensure seamless integration with existing structures, optimize performance, and minimize on-site modifications, which can be both time-consuming and costly. By collaborating closely with clients from design conceptualization through to production, manufacturers can deliver precision-engineered heavy duty steel grating solutions that not only meet but exceed performance expectations, providing significant long-term value and contributing to the overall success and safety of infrastructure projects.

Ensuring Trust: Quality Assurance, Client Support, and Frequently Asked Questions

Trust is paramount in B2B transactions, particularly when dealing with critical infrastructure components like steel grating. Reputable manufacturers uphold this trust through transparent quality assurance protocols, robust certifications, and unwavering commitment to client support. Our products, including our specialized Factory price stainless steel plate steel grating for building construction material, are manufactured under stringent quality management systems, evidenced by international certifications such as ISO 9001:2015. Each batch undergoes rigorous testing, including load deflection tests, material composition analysis, and visual inspections, ensuring compliance with industry standards like ANSI/NAAMM and ASTM. Our long-standing partnerships with leading engineering firms and construction companies, spanning over two decades, underscore our proven reliability and technical prowess in delivering complex grating solutions for major industrial projects globally. Test data for specific load capacities and corrosion resistance are readily available, providing clients with verifiable performance metrics for informed decision-making. We stand by the quality of our products with comprehensive warranty policies, providing peace of mind and long-term assurance for your investment.

Effective client support is integral to the entire project lifecycle, from initial inquiry to post-installation. Our dedicated technical team provides expert consultation to help clients select the optimal steel grating specifications for their unique requirements, considering factors such as load, environment, and budget, including insights into heavy duty steel grating price considerations. We pride ourselves on clear communication regarding lead times and delivery schedules, ensuring that projects remain on track. Our efficient logistics network is designed to facilitate timely and secure delivery of products to various global destinations, even for large-volume orders. Should any technical queries or support needs arise post-delivery, our responsive customer service team is readily available to provide solutions, ensuring seamless project execution and long-term satisfaction. We value continuous feedback from our clients, integrating it into our product development and service enhancement initiatives to maintain our position as a preferred supplier of high-quality steel grating solutions.

Frequently Asked Questions (FAQs)

-

Q: What is the typical lead time for custom steel grating orders?

A: Lead times for custom steel grating vary based on complexity and order volume. Generally, it ranges from 3-4 weeks for standard custom orders to 6-8 weeks for highly specialized or large-scale projects. We provide precise estimates upon project specification.

-

Q: How does the heavy duty steel grating price compare to standard grating?

A: Heavy duty steel grating price is generally higher due to the use of thicker bearing bars and denser configurations, which require more material and specialized fabrication. However, its superior load capacity and durability offer better long-term value for demanding applications.

-

Q: What are the primary surface finishes available for steel grating?

A: The most common finishes include hot-dip galvanization for excellent corrosion resistance, mill finish (uncoated), painted/powder coated for aesthetic and mild protection, and electropolished for stainless steel for enhanced hygiene and appearance.

-

Q: Can your steel grating be used in highly corrosive environments?

A: Yes, for highly corrosive environments, we recommend our stainless steel plate steel grating (grades 304 or 316/316L) or hot-dip galvanized carbon steel grating with a minimum zinc coating thickness. Our experts can advise on the best solution based on your specific corrosive agents.

Conclusion

The strategic integration of high-quality steel grating is fundamental to developing resilient, safe, and efficient industrial and architectural infrastructure. Its inherent strength, combined with versatility in design and material, makes it an optimal choice for diverse applications ranging from petrochemical plants to public walkways. By understanding the intricate manufacturing processes, key technical parameters, and the critical factors influencing heavy duty steel grating price, B2B decision-makers can make informed choices that yield long-term benefits in terms of structural integrity, operational safety, and reduced maintenance costs. Our commitment to precision engineering, adherence to global quality standards, and comprehensive customer support ensures that our steel grating solutions not only meet but exceed the rigorous demands of modern industrial environments. We are dedicated to providing products that embody durability, reliability, and unparalleled performance, contributing to the success and sustainability of your most critical projects.

References

- American National Standards Institute (ANSI) / National Association of Architectural Metal Manufacturers (NAAMM). (2009). Metal Bar Grating Manual (ANSI/NAAMM MBG 531-09).

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems – Requirements.

- ASTM International. (Various Standards). Standards for Steel, Stainless Steel, and Related Alloys.

- The Galvanizers Association. (2023). Benefits of Hot Dip Galvanizing.

- Stainless Steel World. (2022). Corrosion Resistance of Stainless Steels.