Mastering Industrial Infrastructure: The Vital Role of Heavy Duty Steel Grating

In the demanding landscape of modern industrial and urban infrastructure, the integrity and durability of foundational components are paramount. Among these, heavy duty steel grating stands out as an indispensable solution, engineered to withstand extreme loads, harsh environmental conditions, and continuous operational stresses. This robust material is not merely a component but a critical safety and efficiency enabler, providing stable walkways, robust platforms, and efficient drainage systems in environments ranging from bustling urban centers to high-stakes petrochemical facilities. Its unique combination of strength, ventilation, and slip resistance makes it a preferred choice for engineers and project managers seeking long-term, reliable performance. The selection of appropriate industrial steel grating is a complex decision, requiring a deep understanding of material science, manufacturing precision, and application-specific requirements. As industries evolve and infrastructure demands intensify, the role of high-quality heavy duty steel grating becomes even more pronounced, driving innovation in material composites, surface treatments, and fabrication techniques to meet increasingly stringent safety and performance standards globally. This comprehensive guide delves into the intricate world of these essential components, offering insights crucial for B2B decision-makers.

Precision Engineering: The Manufacturing Journey of Heavy Duty Steel Grating

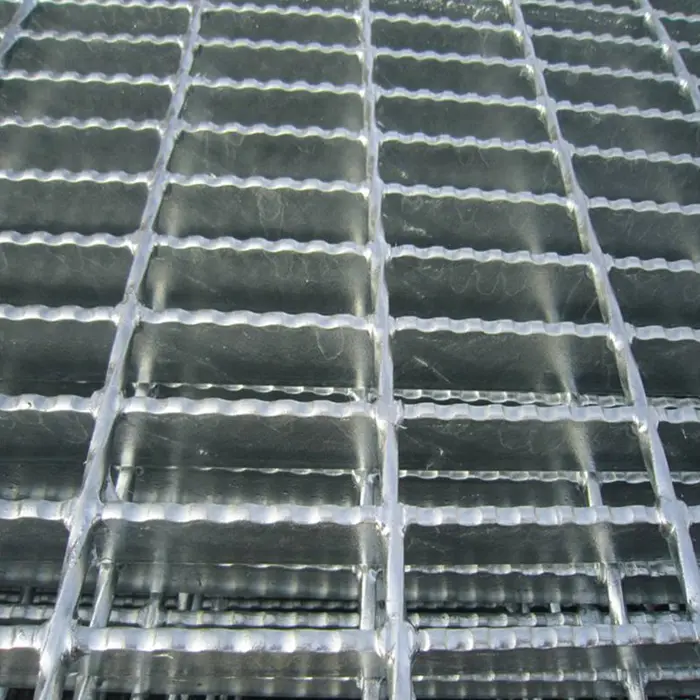

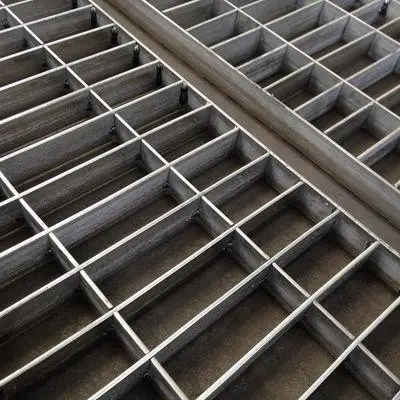

The production of heavy duty steel grating is a sophisticated process, blending advanced engineering with meticulous quality control to ensure superior performance. The journey typically begins with the selection of high-grade raw materials, primarily low carbon steel (e.g., ASTM A36, Q235, S235JR), stainless steel (e.g., SS304, SS316, SS316L for enhanced corrosion resistance), or aluminum alloys (e.g., 6061, 6063 for lighter applications). Each material is chosen based on the intended application's load-bearing, corrosion, and environmental resistance requirements. The core manufacturing processes include electro-forging (pressure welding), press-locking, and swage-locking. Electro-forging, the most common method for industrial steel grating, involves simultaneously applying high amperage and pressure to fuse the bearing bars and cross bars, creating an extremely strong, integral unit. Press-locking employs hydraulic pressure to permanently lock pre-slotted bearing bars and cross bars together, while swage-locking uses a swaging process to deform the cross bars into pre-punched holes in the bearing bars. Following the primary fabrication, panels undergo precision cutting to specified dimensions, banding of edges for structural integrity and aesthetic finish, and often secondary treatments. These treatments can include hot-dip galvanization (conforming to ISO 1461/ASTM A123) for unparalleled corrosion protection, painting, or powder coating for specific aesthetic and protective needs. Throughout the entire manufacturing chain, rigorous quality inspections are conducted, adhering to international standards such as ISO 9001 for quality management systems, ANSI/NAAMM MBG 531-00 for metal bar grating, and various material-specific ASTM standards. This comprehensive approach ensures that each piece of heavy duty steel grating exhibits exceptional strength, longevity, and resistance to wear, capable of providing a service life extending decades even in the most challenging industrial environments, from petrochemical refineries and metallurgy plants to water treatment facilities, often contributing to energy efficiency through optimized light and airflow.

Heavy Duty Steel Grating: Unpacking Key Technical Specifications

Understanding the technical specifications of heavy duty steel grating is fundamental to selecting the right product for any demanding application. These parameters directly influence the grating's load-bearing capacity, span capability, and suitability for specific environments. The primary structural components are the "bearing bars," which carry the main load, and "cross bars," which interconnect the bearing bars to maintain spacing and stability. Key dimensions include the bearing bar size (height and thickness, typically ranging from 25mm to 100mm in height and 3mm to 10mm in thickness for heavy-duty applications), and the spacing between bearing bars (mesh size along the bearing bar direction, commonly 30mm, 40mm, 60mm). Cross bar spacing (mesh size perpendicular to bearing bars, commonly 50mm or 100mm) also plays a role in load distribution and aesthetic. The material grade is crucial; for instance, S235JR for general structural steel, or SS316L for high-corrosion environments like offshore platforms or chemical processing plants. Surface treatments significantly impact longevity and safety; hot-dip galvanization is standard for carbon steel, providing a zinc coating that offers cathodic protection and barrier protection against rust, dramatically extending the lifespan. Plain or serrated surfaces are available, with serrated options providing superior slip resistance, vital for areas prone to moisture, oil, or ice. Load capacity, a critical parameter, is calculated based on bearing bar dimensions, spacing, material properties, and span length. For example, a common industrial steel grating with 40mm x 5mm bearing bars at 30mm spacing can support distributed loads exceeding 100 kN/m² over typical spans, while specialized designs can handle significantly greater point loads. Understanding these intricate details allows engineers to specify grating that not only meets immediate structural requirements but also ensures long-term operational safety and durability, aligning with the stringent performance expectations of modern industrial infrastructure.

Typical Heavy Duty Steel Grating Specifications

| Parameter | Typical Range / Options | Impact / Benefit |

|---|---|---|

| Bearing Bar Height | 25mm - 100mm (1" - 4") | Determines span capability and load capacity. Taller bars for longer spans/heavier loads. |

| Bearing Bar Thickness | 3mm - 10mm (1/8" - 3/8") | Increases rigidity and load-bearing strength. Thicker bars resist deflection better. |

| Bearing Bar Spacing (Pitch) | 30mm, 40mm, 60mm (1-3/16", 1-9/16", 2-3/8") | Affects load distribution, opening size (for drainage/debris), and pedestrian comfort. |

| Cross Bar Spacing | 50mm, 100mm (2", 4") | Contributes to transverse rigidity and panel stability. |

| Material Grades | Low Carbon Steel (Q235/A36), Stainless Steel (304/316/316L), Aluminum (6061/6063) | Determines strength, corrosion resistance, weight, and cost. |

| Surface Treatment | Hot-Dip Galvanized, Painted, Powder Coated, Mill Finish | Enhances corrosion resistance and aesthetic appeal. Hot-dip galvanization is standard for outdoor/industrial use. |

| Surface Type | Plain, Serrated | Serrated provides superior slip resistance, essential for wet or oily environments. |

| Standard Panel Sizes | Typically 6000mm x 1000mm or 20' x 3' (can be customized) | Facilitates efficient manufacturing and installation, reducing waste. |

Versatile Applications and Evolving Trends in Industrial Steel Grating

The adaptability and robust performance of industrial steel grating make it an indispensable component across a vast array of sectors and applications. From supporting heavy machinery in manufacturing plants to facilitating safe pedestrian access in public spaces, its utility is broad and critical. Common application scenarios include industrial platforms, mezzanines, and walkways where a high strength-to-weight ratio is required; trench and drainage covers for efficient water runoff in urban roads, factories, and airports, preventing accumulation and maintaining safety; and safety barriers or infill panels due to its inherent strength and open structure. Specific industries that heavily rely on steel grating heavy duty solutions include petrochemical facilities, oil and gas platforms, power generation plants, wastewater treatment works, metallurgy, mining, food processing, and shipbuilding, where resistance to corrosion, high loads, and extreme temperatures are non-negotiable. Current industry trends are pushing the boundaries of traditional grating applications. There's a growing emphasis on intelligent infrastructure integration, where grating might incorporate sensor technology for structural health monitoring or smart drainage systems. Sustainability is another key driver, with increasing demand for grating manufactured from recycled content and designs that offer extended lifespans, minimizing replacement cycles and environmental impact. Advances in surface coatings and composite materials are also enhancing performance, offering improved slip resistance even in highly corrosive or oily environments, and better thermal resistance for specialized industrial processes. Furthermore, customization has become a crucial aspect, with clients frequently requiring bespoke designs, unique shapes, specific load ratings, and specialized finishes to perfectly fit complex architectural and engineering projects, moving beyond standard panels to integrated, tailor-made solutions.

The Core Advantages of High-Performance Steel Grating Heavy Duty Solutions

The widespread adoption of steel grating heavy duty solutions across diverse industrial and commercial sectors is testament to their multifaceted advantages, which extend far beyond simple load-bearing capability. One of the foremost benefits is their exceptional strength-to-weight ratio; despite their robust load capacity, these gratings are relatively lightweight, simplifying installation and reducing structural support requirements, thereby lowering overall construction costs. Durability is another hallmark, with high-quality steel, often fortified by hot-dip galvanization, providing superior resistance to impact, abrasion, and the corrosive effects of chemicals, moisture, and extreme temperatures. This inherent resilience translates into an extended service life and minimal maintenance requirements, yielding significant long-term savings. Furthermore, the open grid design of grating offers unparalleled benefits: it ensures excellent drainage of liquids and debris, preventing hazardous accumulations and maintaining clean surfaces. This characteristic is particularly vital in industrial settings where spills are common or in urban drainage systems. Superior ventilation is also a direct result, allowing for natural light penetration, which can reduce the need for artificial lighting and improve air circulation, contributing to a safer and more energy-efficient environment. The design also facilitates heat dissipation, which is crucial in high-temperature industrial zones. Moreover, heavy duty steel grating provides inherent slip resistance, especially when specified with a serrated surface, significantly enhancing pedestrian and vehicular safety in challenging conditions. Ease of installation, often involving simple clips or welding, and the ability to be custom-fabricated to precise dimensions, further underscore its practical advantages for complex engineering projects. These combined attributes make high-performance steel grating an optimal choice for safety, operational efficiency, and cost-effectiveness in demanding applications.

Choosing the Right Partner: Manufacturer Considerations and Customization for Heavy Duty Steel Grating

Selecting the appropriate manufacturer for your heavy duty steel grating requirements is as crucial as defining the product specifications themselves. A reputable manufacturer doesn't just supply a product; they provide a comprehensive solution backed by expertise, reliability, and robust support. Key criteria for evaluation include a manufacturer's proven track record and extensive experience in the industry, evidenced by their portfolio of successful projects and years in operation. Crucially, look for companies that adhere to stringent quality management systems, holding certifications such as ISO 9001, which demonstrates their commitment to consistent quality across all production phases. Production capacity is another vital factor, ensuring that the manufacturer can meet your project timelines, whether for large-scale infrastructure projects or urgent replacements. Engineering support is paramount; a good partner will offer technical assistance from design conceptualization through to installation, providing load calculations, span tables, and detailed shop drawings. Their customization capabilities are equally important for modern complex projects. Industrial steel grating often requires bespoke solutions: unique panel shapes for irregular spaces, specific cut-outs for pipes or equipment, specialized banding, or tailored finishes like custom colors or specific non-slip treatments. A manufacturer with advanced fabrication technology and in-house engineering teams can readily accommodate such complex requirements, ensuring precise fit and optimal performance. After-sales service, including warranty provisions and prompt technical assistance, further distinguishes a reliable partner from the rest, guaranteeing long-term satisfaction and support for your investment in industrial steel grating.

Demonstrated Performance: Case Studies in Heavy Duty Steel Grating Deployment

The true value of heavy duty steel grating is best illustrated through its successful deployment in diverse, challenging environments. Consider the case of a major petrochemical complex, where the operational safety and efficiency of elevated platforms and walkways are critical. Here, electro-forged steel grating, typically with 40mm x 5mm bearing bars and hot-dip galvanized for superior corrosion resistance against chemical spills and humidity, was chosen. Its high load-bearing capacity effectively supported heavy equipment and personnel, while the open mesh design ensured efficient drainage of process fluids and excellent ventilation, mitigating heat buildup and enhancing air quality in enclosed areas. The serrated surface provided crucial slip resistance, significantly reducing accident risks in potentially oily or wet conditions. Another compelling example is a large-scale urban road drainage project, where the product "High Quality Urban Road Drainage Steel Grating Durable Cemented Carbide Floor Warehouse Use Aluminium Stainless Steel Iron" was implemented. For this application, industrial steel grating with robust bearing bars and smaller mesh sizes was designed to accommodate heavy vehicular traffic while effectively channeling stormwater away, preventing flooding and maintaining road integrity. The durability of the galvanized steel ensured a prolonged service life, resisting wear from constant traffic and corrosive elements present in urban runoff, validating its suitability for long-term municipal infrastructure. Lastly, in an offshore drilling rig, exposed to relentless saltwater corrosion and extreme weather, specialized steel grating heavy duty made from marine-grade stainless steel (SS316L) was utilized for helipads, walkovers, and equipment platforms. Its inherent corrosion resistance, combined with superior structural integrity, ensured safety and operational continuity, demonstrating its indispensable role in environments where failure is not an option and maximum durability is critical. These cases underscore the versatility, reliability, and essential benefits of correctly specified and expertly manufactured heavy duty steel grating solutions.

Frequently Asked Questions about Industrial Steel Grating

-

Q1: What is the typical lifespan of heavy duty steel grating?

The lifespan of heavy duty steel grating is significantly influenced by its material, surface treatment, and the environmental conditions it's exposed to. Hot-dip galvanized carbon steel grating, when properly installed in typical industrial environments, can last 20 to 50 years or even longer. Stainless steel variants offer superior longevity in highly corrosive conditions, potentially exceeding 60 years. Regular inspection and minimal maintenance can further extend its service life.

-

Q2: How is the load capacity of industrial steel grating determined?

The load capacity of industrial steel grating is determined by several factors, including the dimensions of the bearing bars (height and thickness), the spacing between them, the span length, and the material's yield strength. Manufacturers provide load tables or engineering calculations based on industry standards (e.g., ANSI/NAAMM MBG 531-00) to specify safe working loads for various configurations. Custom designs can be engineered to meet specific project load requirements.

-

Q3: What are the best materials for steel grating in corrosive environments?

For highly corrosive environments, stainless steel grades like SS304, SS316, or SS316L are ideal due to their inherent resistance to rust and chemical degradation. While hot-dip galvanized carbon steel provides excellent protection for many industrial settings, stainless steel offers superior performance in extreme conditions such as those found in chemical plants, offshore platforms, or certain wastewater treatment facilities. Aluminum grating is also corrosion-resistant but typically used for lighter loads.

-

Q4: Can heavy duty steel grating be customized for specific projects?

Absolutely. Leading manufacturers of heavy duty steel grating offer extensive customization options to meet unique project specifications. This includes custom panel dimensions, irregular shapes, cut-outs for pipework or machinery, specialized banding, different bearing bar configurations, and a variety of surface finishes (e.g., specific paint colors, anti-slip coatings). Engineering teams work closely with clients to design grating solutions that perfectly integrate with complex architectural and operational requirements.

-

Q5: What are the typical delivery times and warranty for heavy duty steel grating?

Delivery times for steel grating heavy duty vary depending on the order size, customization complexity, and current production schedules. Standard orders might have a lead time of 2-4 weeks, while highly customized or large-volume orders could take longer. Reputable manufacturers typically offer warranties ranging from 5 to 10 years against manufacturing defects and material failures under normal use, demonstrating their commitment to product quality and customer satisfaction. It's always best to discuss specific lead times and warranty details with your chosen supplier.

Ensuring Your Investment: Quality, Delivery, and Support for Steel Grating Heavy Duty

Investing in steel grating heavy duty solutions requires confidence not just in the product itself, but in the entire supply chain, from manufacturing quality to post-purchase support. Reputable suppliers implement rigorous quality assurance protocols at every stage, from raw material inspection to final product testing. This includes material certification, dimensional checks, weld integrity testing, load deflection tests, and adherence to coating thickness standards for galvanization. Such meticulous quality control ensures that every panel of heavy duty steel grating meets specified performance criteria and international industry benchmarks. Regarding delivery, efficient logistics are crucial, especially for time-sensitive industrial projects. Leading manufacturers leverage optimized production schedules and robust shipping networks to provide reliable lead times, often offering expedited options for urgent requirements. Standard lead times can range from 2 to 4 weeks for common configurations, extending for highly customized or exceptionally large orders. Furthermore, a strong commitment to customer support and a clear warranty policy are hallmarks of a trustworthy partner. This includes readily available technical assistance for design and installation queries, responsive after-sales service, and a comprehensive warranty—typically covering manufacturing defects for a period of 5 to 10 years. This holistic approach to quality, delivery, and ongoing support ensures that your investment in industrial steel grating is protected, providing long-term reliability and peace of mind for critical infrastructure applications.

Conclusion

In conclusion, heavy duty steel grating is an indispensable component in the bedrock of modern industrial and urban infrastructure. Its unparalleled strength, durability, and functional design make it a superior choice for a multitude of demanding applications, from complex industrial platforms to vital urban drainage systems. The careful selection of materials, precision manufacturing processes, and rigorous quality controls ensure that these gratings deliver exceptional performance, safety, and longevity even in the most challenging environments. As industries continue to evolve, demanding more robust, sustainable, and intelligent solutions, the advancements in industrial steel grating technology will undoubtedly play a pivotal role in shaping safer, more efficient, and resilient infrastructure worldwide. For B2B decision-makers, understanding the technical nuances, application versatility, and the importance of partnering with a reliable manufacturer are key to unlocking the full potential and long-term value of these essential engineering components.

References:

- American National Standards Institute (ANSI) / National Association of Architectural Metal Manufacturers (NAAMM). (2000). Metal Bar Grating Manual (MBG 531). NAAMM.

- International Organization for Standardization (ISO). (2019). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods. ISO.

- ASTM International. (2018). ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International.

- ASCE/SEI. (2016). Minimum Design Loads and Associated Criteria for Buildings and Other Structures (ASCE/SEI 7-16). American Society of Civil Engineers.

2.webp)