Navigating Industrial Safety: The Evolution of Non-Slip Metal Solutions

In demanding industrial environments, ensuring worker safety and operational efficiency hinges on reliable infrastructure. Critical components like walkways, stair treads, and floor plates are exposed to relentless wear, corrosive agents, and often, hazardous conditions that necessitate superior slip resistance and load-bearing capabilities. Traditional solutions frequently fall short, leading to maintenance challenges, safety incidents, and costly downtime. The industry's evolution has led to advanced engineering of metal surfaces, moving beyond basic designs to sophisticated systems that offer unparalleled safety and durability. This article delves into the technical intricacies, application benefits, and strategic considerations of high-performance industrial metal solutions, emphasizing those designed for optimal safety and longevity.

Specifically, we will explore the nuances of products like the non barbed wire type of industrial grating and its applications in non-slip metal walkways and stair treads, crucial for maintaining safety standards in hazardous areas. Understanding the distinction from defensive wire products, here "non barbed wire" refers to engineered metal structures that prioritize user safety by eliminating sharp protrusions, ensuring a smooth, yet highly friction-resistant surface.

Unpacking the Manufacturing Excellence of High-Performance Non-Slip Surfaces

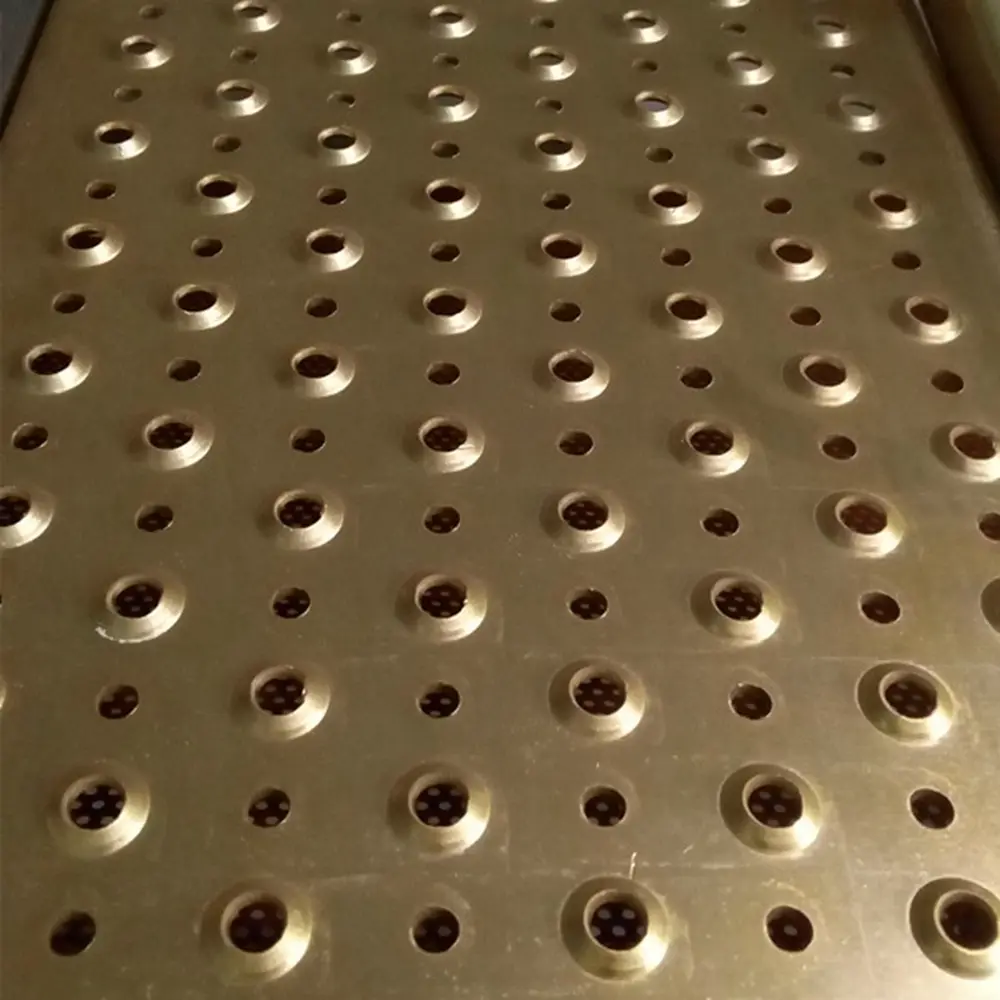

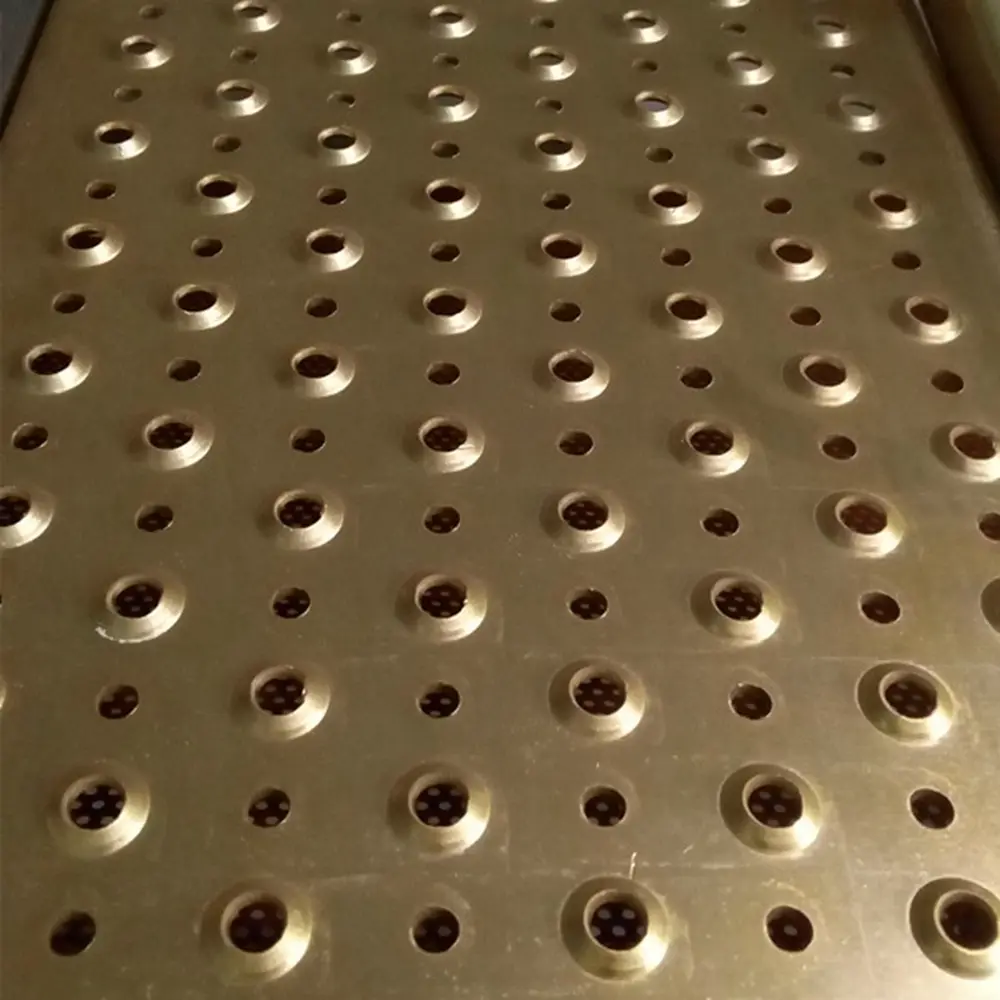

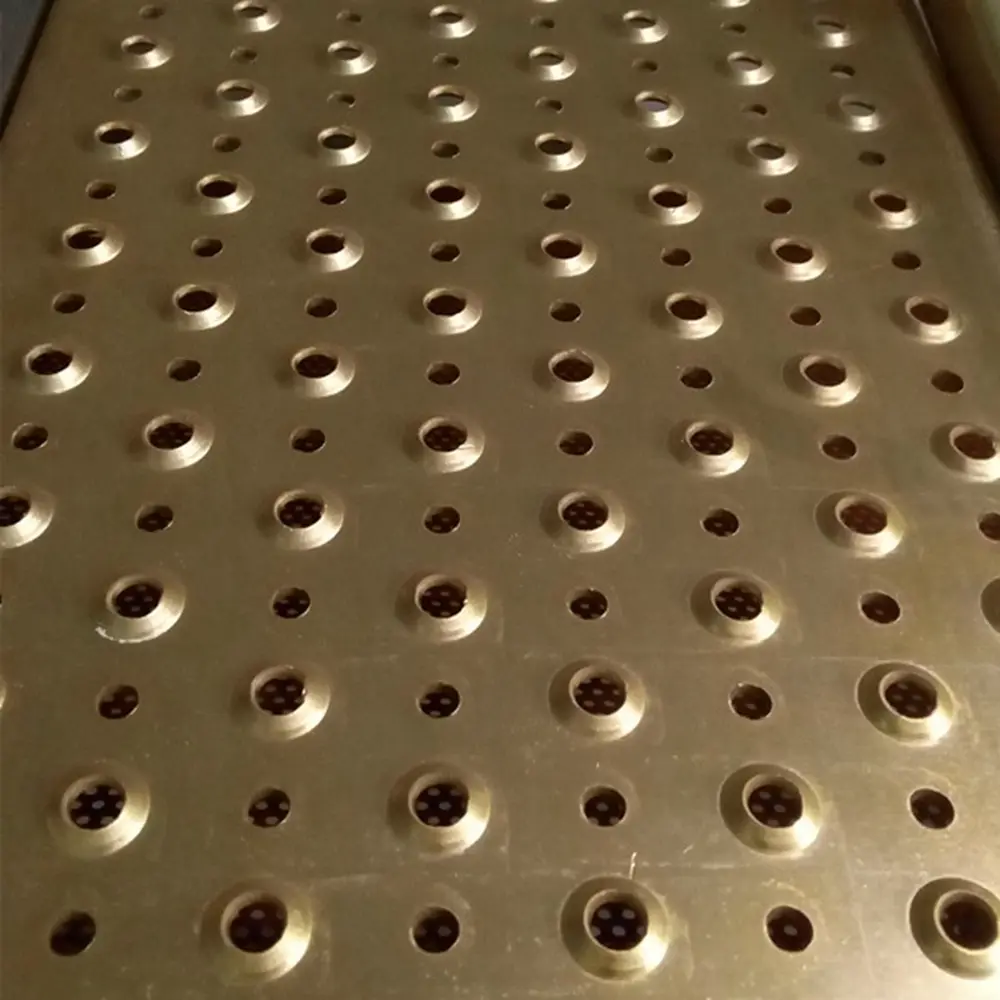

The creation of high load-bearing capacity and high safety non-slip metal walkway stair treads, along with premium non slip floor plate and non slip metal grating, is a meticulous process demanding precision engineering and stringent quality control. The journey begins with the selection of premium materials such as high-strength carbon steel, stainless steel (304, 316L), or aluminum alloys, chosen for their inherent corrosion resistance, strength-to-weight ratio, and suitability for specific environments (e.g., petrochemical, marine, food processing). Manufacturing processes typically involve advanced techniques like CNC laser cutting or plasma cutting for precise component shaping, followed by state-of-the-art welding (MIG, TIG, or robotic welding) to ensure structural integrity and seamless joints. The most critical aspect for non-slip properties involves specialized surface treatments, including serrated edges, perforated patterns, or embossed textures, which significantly enhance friction coefficients under wet or oily conditions.

Post-fabrication, these products undergo a rigorous surface finishing process, often involving hot-dip galvanization (conforming to ASTM A123/A123M standards) for superior corrosion protection, or powder coating for aesthetic appeal and additional durability. Critical inspection standards, such as ISO 9001 for quality management, ANSI/NAAMM MBG 531 for metal bar grating, and relevant OSHA guidelines for walking-working surfaces, are strictly adhered to throughout production. The typical service life of such engineered solutions can exceed 20-30 years in non-corrosive environments and 10-15 years even in highly aggressive industrial settings, significantly outperforming conventional materials. Their robust design inherently contributes to energy savings by reducing the need for frequent replacements and maintenance, while their inherent corrosion resistance minimizes environmental impact.

Technical Specifications and Performance Metrics

To underscore the superior capabilities of modern non barbed wire industrial safety surfaces, it's essential to examine their core technical parameters. These specifications directly translate into the product's suitability for high-load applications and extreme operating conditions. Below is a comparative table detailing common parameters for various types of industrial metal grating and floor plates, showcasing the robust engineering behind these solutions.

Comparative Table: Key Parameters of Non-Slip Metal Solutions

| Parameter | Serrated Bar Grating | Perforated Non-Slip Plate | Diamond Safety Grating |

|---|---|---|---|

| Material Options | Carbon Steel, SS304/316, Aluminum | Carbon Steel, SS304/316, Galvanized Steel | Carbon Steel, Aluminum |

| Standard Thickness (mm) | 3mm - 10mm (Bearing Bars) | 2mm - 6mm | 2.5mm - 5mm |

| Load Capacity (kN/m²) | Up to 90 kN/m² (Span dependent) | Up to 25 kN/m² | Up to 30 kN/m² |

| Slip Resistance (Coefficient of Friction) | > 0.8 (Dry), > 0.6 (Wet) | > 0.9 (Dry), > 0.7 (Wet/Oily) | > 0.85 (Dry), > 0.65 (Wet) |

| Corrosion Resistance | Excellent (Galvanized/SS) | Very Good (Galvanized/SS) | Good (Galvanized/Aluminum) |

| Drainage Performance | Excellent (Open Mesh) | Good (Perforations) | Moderate (Small Openings) |

These values represent typical performance under controlled conditions. Actual field performance can vary based on specific environmental factors and maintenance regimes. The selection of the appropriate non slip floor plate or non slip metal grating should always be guided by a thorough assessment of the operational environment, including expected load, exposure to chemicals, and pedestrian/vehicular traffic volume.

Applications, Advantages, and Customization Capabilities

The versatility and robust nature of high-performance metal grating and floor plates make them indispensable across a spectrum of industrial sectors. From the petrochemical industry, where resistance to corrosive chemicals and extreme temperatures is paramount, to metallurgy where heavy loads and abrasive conditions are common, and in water treatment facilities requiring superior anti-corrosion properties and excellent drainage, these solutions provide critical safety and operational advantages. Their inherent design as non barbed wire systems ensures that personnel can move safely without risk of cuts or snags, a crucial factor in active industrial settings.

- Enhanced Safety: Superior slip resistance, even in the presence of water, oil, or grease, drastically reduces the risk of slips, trips, and falls.

- Durability & Longevity: High-grade materials and advanced manufacturing ensure extended product lifespan, reducing replacement frequency and associated costs.

- Corrosion Resistance: Options like galvanized steel or stainless steel offer excellent protection against various corrosive agents, crucial for chemical plants and offshore platforms.

- High Load-Bearing Capacity: Engineered to withstand significant static and dynamic loads, making them suitable for heavy machinery areas and high-traffic zones.

- Maintenance Efficiency: Easy to clean and inspect, these surfaces minimize maintenance downtime and simplify operational upkeep.

Beyond standard offerings, leading manufacturers provide extensive customization options. This includes tailored dimensions, specific material grades, unique non-slip patterns, and integrated components for complex installations. Whether it's a specialized industrial walkway, a custom-designed non slip floor plate for a machinery platform, or bespoke stair treads for an access tower, bespoke solutions ensure optimal fit, performance, and compliance with project-specific regulations. Our engineers collaborate closely with clients from conceptualization to deployment, ensuring that every solution is optimized for the unique challenges of their operational environment.

Ensuring Trust: Certifications, Warranty, and Client Success

Trust is paramount in the B2B sector, especially concerning safety-critical infrastructure. Our commitment to quality is validated through adherence to international standards and certifications. We hold ISO 9001:2015 certification for quality management systems, ensuring consistent product quality from design to delivery. Our products meet or exceed relevant ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute) standards for material strength and grating performance. Furthermore, internal testing protocols, including rigorous load tests and slip resistance evaluations (e.g., using the British Pendulum Test or tribometer), consistently demonstrate the superior performance of our non slip metal grating and stair treads.

Our confidence in our product quality is reflected in our comprehensive warranty policies, typically ranging from 5 to 10 years, covering material defects and manufacturing flaws. This provides our clients with long-term peace of mind regarding their investment in non barbed wire industrial solutions. We pride ourselves on transparent delivery timelines, with standard orders typically processed and shipped within 3-4 weeks, while complex custom solutions may require 6-8 weeks, depending on design complexity and material availability. Our dedicated customer support team offers end-to-end assistance, from initial consultation and technical specifications review to post-installation support and maintenance advice. Feedback from clients in the power generation and chemical processing sectors consistently highlights the durability and enhanced safety our products bring to their operational sites, often citing a significant reduction in slip-related incidents since implementation.

Frequently Asked Questions (FAQs) about Non-Slip Metal Solutions

Q1: What is the primary difference between traditional grating and a non barbed wire non-slip solution?

Traditional gratings may offer basic load support, but a non barbed wire non-slip solution, in the context of industrial surfaces, specifically refers to metal gratings and plates engineered with specialized surface profiles (e.g., serrations, perforations, or embossed patterns) to significantly enhance the coefficient of friction, thereby preventing slips, particularly in wet, oily, or icy conditions, without having any sharp or aggressive elements found in barbed wire.

Q2: How do you determine the correct material for a specific application?

Material selection is critical and depends on environmental factors such as exposure to corrosive chemicals, extreme temperatures, required load capacity, and aesthetic considerations. For highly corrosive environments, stainless steel (e.g., SS316L) is recommended. For general industrial use with good corrosion protection, hot-dip galvanized carbon steel is a cost-effective choice. Aluminum is preferred where weight is a critical factor.

Q3: Can these non slip metal grating products be custom fabricated to specific dimensions?

Absolutely. Custom fabrication is a core service. We can design and manufacture non slip floor plate, grating, and stair tread solutions to precise dimensions, shapes, and load requirements, including integration with existing structures. Our engineering team uses advanced CAD software to ensure perfect fit and functionality for unique project needs.

Q4: What is the expected lead time for order delivery?

Standard product orders typically have a lead time of 3-4 weeks from order confirmation to dispatch. For highly customized or large-volume projects, lead times may extend to 6-8 weeks or more, depending on complexity and material sourcing. We maintain transparent communication throughout the production process to keep clients informed.

Conclusion: Investing in Superior Industrial Safety and Performance

The demand for high load-bearing capacity, high safety non slip metal walkway stair treads, and robust non slip metal grating continues to grow as industries prioritize worker safety and operational longevity. By moving beyond traditional solutions to embrace advanced engineering and materials, businesses can significantly mitigate risks, reduce maintenance costs, and enhance overall productivity. The emphasis on products that function as non barbed wire surfaces—meaning safe, smooth, yet highly friction-resistant—marks a pivotal shift towards human-centric industrial design. Partnering with a manufacturer that combines technical expertise, stringent quality control, and a commitment to customized solutions ensures that your industrial infrastructure is not just compliant, but truly optimized for peak performance and unwavering safety.

References

- American Society for Testing and Materials (ASTM) Standards for Steel and Galvanizing.

- International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

- National Association of Architectural Metal Manufacturers (NAAMM) MBG 531-15: Metal Bar Grating Manual.

- Occupational Safety and Health Administration (OSHA) Walking-Working Surfaces Guidelines.

Navigating Industrial Safety: The Evolution of Non-Slip Metal Solutions

In demanding industrial environments, ensuring worker safety and operational efficiency hinges on reliable infrastructure. Critical components like walkways, stair treads, and floor plates are exposed to relentless wear, corrosive agents, and often, hazardous conditions that necessitate superior slip resistance and load-bearing capabilities. Traditional solutions frequently fall short, leading to maintenance challenges, safety incidents, and costly downtime. The industry's evolution has led to advanced engineering of metal surfaces, moving beyond basic designs to sophisticated systems that offer unparalleled safety and durability. This article delves into the technical intricacies, application benefits, and strategic considerations of high-performance industrial metal solutions, emphasizing those designed for optimal safety and longevity.

Specifically, we will explore the nuances of products like the non barbed wire type of industrial grating and its applications in non-slip metal walkways and stair treads, crucial for maintaining safety standards in hazardous areas. Understanding the distinction from defensive wire products, here "non barbed wire" refers to engineered metal structures that prioritize user safety by eliminating sharp protrusions, ensuring a smooth, yet highly friction-resistant surface. This crucial design aspect makes them ideal for environments where personnel interaction is constant, setting them apart from conventional, less safe alternatives.

Unpacking the Manufacturing Excellence of High-Performance Non-Slip Surfaces

The creation of high load-bearing capacity and high safety non-slip metal walkway stair treads, along with premium non slip floor plate and non slip metal grating, is a meticulous process demanding precision engineering and stringent quality control. The journey begins with the selection of premium materials such as high-strength carbon steel, stainless steel (304, 316L), or aluminum alloys, chosen for their inherent corrosion resistance, strength-to-weight ratio, and suitability for specific environments (e.g., petrochemical, marine, food processing). Manufacturing processes typically involve advanced techniques like CNC laser cutting or plasma cutting for precise component shaping, followed by state-of-the-art welding (MIG, TIG, or robotic welding) to ensure structural integrity and seamless joints. The most critical aspect for non-slip properties involves specialized surface treatments, including serrated edges, perforated patterns, or embossed textures, which significantly enhance friction coefficients under wet or oily conditions. This engineering ensures that these metal structures function effectively as a non barbed wire surface, prioritizing safe and comfortable human interaction.

Post-fabrication, these products undergo a rigorous surface finishing process, often involving hot-dip galvanization (conforming to ASTM A123/A123M standards) for superior corrosion protection, or powder coating for aesthetic appeal and additional durability. Critical inspection standards, such as ISO 9001 for quality management, ANSI/NAAMM MBG 531 for metal bar grating, and relevant OSHA guidelines for walking-working surfaces, are strictly adhered to throughout production. The typical service life of such engineered solutions can exceed 20-30 years in non-corrosive environments and 10-15 years even in highly aggressive industrial settings, significantly outperforming conventional materials. Their robust design inherently contributes to energy savings by reducing the need for frequent replacements and maintenance, while their inherent corrosion resistance minimizes environmental impact. This holistic approach ensures the longevity and safety performance of every non barbed wire product leaving our facility.

Technical Specifications and Performance Metrics

To underscore the superior capabilities of modern non barbed wire industrial safety surfaces, it's essential to examine their core technical parameters. These specifications directly translate into the product's suitability for high-load applications and extreme operating conditions. Below is a comparative table detailing common parameters for various types of industrial metal grating and floor plates, showcasing the robust engineering behind these solutions.

Comparative Table: Key Parameters of Non-Slip Metal Solutions

| Parameter | Serrated Bar Grating | Perforated Non-Slip Plate | Diamond Safety Grating |

|---|---|---|---|

| Material Options | Carbon Steel, SS304/316, Aluminum | Carbon Steel, SS304/316, Galvanized Steel | Carbon Steel, Aluminum |

| Standard Thickness (mm) | 3mm - 10mm (Bearing Bars) | 2mm - 6mm | 2.5mm - 5mm |

| Load Capacity (kN/m²) | Up to 90 kN/m² (Span dependent) | Up to 25 kN/m² | Up to 30 kN/m² |

| Slip Resistance (Coefficient of Friction) | > 0.8 (Dry), > 0.6 (Wet) | > 0.9 (Dry), > 0.7 (Wet/Oily) | > 0.85 (Dry), > 0.65 (Wet) |

| Corrosion Resistance | Excellent (Galvanized/SS) | Very Good (Galvanized/SS) | Good (Galvanized/Aluminum) |

| Drainage Performance | Excellent (Open Mesh) | Good (Perforations) | Moderate (Small Openings) |

These values represent typical performance under controlled conditions. Actual field performance can vary based on specific environmental factors and maintenance regimes. The selection of the appropriate non slip floor plate or non slip metal grating should always be guided by a thorough assessment of the operational environment, including expected load, exposure to chemicals, and pedestrian/vehicular traffic volume. This ensures optimal safety and longevity from your industrial non barbed wire solution.

Applications, Advantages, and Customization Capabilities

The versatility and robust nature of high-performance metal grating and floor plates make them indispensable across a spectrum of industrial sectors. From the petrochemical industry, where resistance to corrosive chemicals and extreme temperatures is paramount, to metallurgy where heavy loads and abrasive conditions are common, and in water treatment facilities requiring superior anti-corrosion properties and excellent drainage, these solutions provide critical safety and operational advantages. Their inherent design as non barbed wire systems ensures that personnel can move safely without risk of cuts or snags, a crucial factor in active industrial settings. This commitment to safety is a hallmark of truly advanced non barbed wire products.

- Enhanced Safety: Superior slip resistance, even in the presence of water, oil, or grease, drastically reduces the risk of slips, trips, and falls.

- Durability & Longevity: High-grade materials and advanced manufacturing ensure extended product lifespan, reducing replacement frequency and associated costs.

- Corrosion Resistance: Options like galvanized steel or stainless steel offer excellent protection against various corrosive agents, crucial for chemical plants and offshore platforms.

- High Load-Bearing Capacity: Engineered to withstand significant static and dynamic loads, making them suitable for heavy machinery areas and high-traffic zones.

- Maintenance Efficiency: Easy to clean and inspect, these surfaces minimize maintenance downtime and simplify operational upkeep.

Beyond standard offerings, leading manufacturers provide extensive customization options. This includes tailored dimensions, specific material grades, unique non-slip patterns, and integrated components for complex installations. Whether it's a specialized industrial walkway, a custom-designed non slip floor plate for a machinery platform, or bespoke stair treads for an access tower, bespoke solutions ensure optimal fit, performance, and compliance with project-specific regulations. Our engineers collaborate closely with clients from conceptualization to deployment, ensuring that every solution is optimized for the unique challenges of their operational environment.

Ensuring Trust: Certifications, Warranty, and Client Success

Trust is paramount in the B2B sector, especially concerning safety-critical infrastructure. Our commitment to quality is validated through adherence to international standards and certifications. We hold ISO 9001:2015 certification for quality management systems, ensuring consistent product quality from design to delivery. Our products meet or exceed relevant ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute) standards for material strength and grating performance. Furthermore, internal testing protocols, including rigorous load tests and slip resistance evaluations (e.g., using the British Pendulum Test or tribometer), consistently demonstrate the superior performance of our non slip metal grating and stair treads.

Our confidence in our product quality is reflected in our comprehensive warranty policies, typically ranging from 5 to 10 years, covering material defects and manufacturing flaws. This provides our clients with long-term peace of mind regarding their investment in non barbed wire industrial solutions. We pride ourselves on transparent delivery timelines, with standard orders typically processed and shipped within 3-4 weeks, while complex custom solutions may require 6-8 weeks, depending on design complexity and material availability. Our dedicated customer support team offers end-to-end assistance, from initial consultation and technical specifications review to post-installation support and maintenance advice. Feedback from clients in the power generation and chemical processing sectors consistently highlights the durability and enhanced safety our products bring to their operational sites, often citing a significant reduction in slip-related incidents since implementation.

Frequently Asked Questions (FAQs) about Non-Slip Metal Solutions

Q1: What is the primary difference between traditional grating and a non barbed wire non-slip solution?

Traditional gratings may offer basic load support, but a non barbed wire non-slip solution, in the context of industrial surfaces, specifically refers to metal gratings and plates engineered with specialized surface profiles (e.g., serrations, perforations, or embossed patterns) to significantly enhance the coefficient of friction, thereby preventing slips, particularly in wet, oily, or icy conditions, without having any sharp or aggressive elements found in barbed wire.

Q2: How do you determine the correct material for a specific application?

Material selection is critical and depends on environmental factors such as exposure to corrosive chemicals, extreme temperatures, required load capacity, and aesthetic considerations. For highly corrosive environments, stainless steel (e.g., SS316L) is recommended. For general industrial use with good corrosion protection, hot-dip galvanized carbon steel is a cost-effective choice. Aluminum is preferred where weight is a critical factor.

Q3: Can these non slip metal grating products be custom fabricated to specific dimensions?

Absolutely. Custom fabrication is a core service. We can design and manufacture non slip floor plate, grating, and stair tread solutions to precise dimensions, shapes, and load requirements, including integration with existing structures. Our engineering team uses advanced CAD software to ensure perfect fit and functionality for unique project needs.

Q4: What is the expected lead time for order delivery?

Standard product orders typically have a lead time of 3-4 weeks from order confirmation to dispatch. For highly customized or large-volume projects, lead times may extend to 6-8 weeks or more, depending on complexity and material sourcing. We maintain transparent communication throughout the production process to keep clients informed.

Conclusion: Investing in Superior Industrial Safety and Performance

The demand for high load-bearing capacity, high safety non slip metal walkway stair treads, and robust non slip metal grating continues to grow as industries prioritize worker safety and operational longevity. By moving beyond traditional solutions to embrace advanced engineering and materials, businesses can significantly mitigate risks, reduce maintenance costs, and enhance overall productivity. The emphasis on products that function as non barbed wire surfaces—meaning safe, smooth, yet highly friction-resistant—marks a pivotal shift towards human-centric industrial design. Partnering with a manufacturer that combines technical expertise, stringent quality control, and a commitment to customized solutions ensures that your industrial infrastructure is not just compliant, but truly optimized for peak performance and unwavering safety. This holistic approach ensures long-term value from your investment in advanced non barbed wire solutions.

References

- American Society for Testing and Materials (ASTM) Standards for Steel and Galvanizing.

- International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

- National Association of Architectural Metal Manufacturers (NAAMM) MBG 531-15: Metal Bar Grating Manual.

- Occupational Safety and Health Administration (OSHA) Walking-Working Surfaces Guidelines.

Navigating Industrial Safety: The Evolution of Non-Slip Metal Solutions

In demanding industrial environments, ensuring worker safety and operational efficiency hinges on reliable infrastructure. Critical components like walkways, stair treads, and floor plates are exposed to relentless wear, corrosive agents, and often, hazardous conditions that necessitate superior slip resistance and load-bearing capabilities. Traditional solutions frequently fall short, leading to maintenance challenges, safety incidents, and costly downtime. The industry's evolution has led to advanced engineering of metal surfaces, moving beyond basic designs to sophisticated systems that offer unparalleled safety and durability. This article delves into the technical intricacies, application benefits, and strategic considerations of high-performance industrial metal solutions, emphasizing those designed for optimal safety and longevity.

Specifically, we will explore the nuances of products like the non barbed wire type of industrial grating and its applications in non-slip metal walkways and stair treads, crucial for maintaining safety standards in hazardous areas. Understanding the distinction from defensive wire products, here "non barbed wire" refers to engineered metal structures that prioritize user safety by eliminating sharp protrusions, ensuring a smooth, yet highly friction-resistant surface. This crucial design aspect makes them ideal for environments where personnel interaction is constant, setting them apart from conventional, less safe alternatives, thereby enhancing the overall safety footprint of industrial facilities.

Unpacking the Manufacturing Excellence of High-Performance Non-Slip Surfaces

The creation of high load-bearing capacity and high safety non-slip metal walkway stair treads, along with premium non slip floor plate and non slip metal grating, is a meticulous process demanding precision engineering and stringent quality control. The journey begins with the selection of premium materials such as high-strength carbon steel, stainless steel (304, 316L), or aluminum alloys, chosen for their inherent corrosion resistance, strength-to-weight ratio, and suitability for specific environments (e.g., petrochemical, marine, food processing). Manufacturing processes typically involve advanced techniques like CNC laser cutting or plasma cutting for precise component shaping, followed by state-of-the-art welding (MIG, TIG, or robotic welding) to ensure structural integrity and seamless joints. The most critical aspect for non-slip properties involves specialized surface treatments, including serrated edges, perforated patterns, or embossed textures, which significantly enhance friction coefficients under wet or oily conditions. This engineering ensures that these metal structures function effectively as a non barbed wire surface, prioritizing safe and comfortable human interaction in high-traffic or hazardous areas.

Post-fabrication, these products undergo a rigorous surface finishing process, often involving hot-dip galvanization (conforming to ASTM A123/A123M standards) for superior corrosion protection, or powder coating for aesthetic appeal and additional durability. Critical inspection standards, such as ISO 9001 for quality management, ANSI/NAAMM MBG 531 for metal bar grating, and relevant OSHA guidelines for walking-working surfaces, are strictly adhered to throughout production. The typical service life of such engineered solutions can exceed 20-30 years in non-corrosive environments and 10-15 years even in highly aggressive industrial settings, significantly outperforming conventional materials. Their robust design inherently contributes to energy savings by reducing the need for frequent replacements and maintenance, while their inherent corrosion resistance minimizes environmental impact. This holistic approach ensures the longevity and safety performance of every non barbed wire product leaving our facility, providing a reliable foundation for industrial operations.

Technical Specifications and Performance Metrics

To underscore the superior capabilities of modern non barbed wire industrial safety surfaces, it's essential to examine their core technical parameters. These specifications directly translate into the product's suitability for high-load applications and extreme operating conditions. Below is a comparative table detailing common parameters for various types of industrial metal grating and floor plates, showcasing the robust engineering behind these solutions. This data-driven approach allows for informed decision-making when selecting the right product for critical infrastructure.

Comparative Table: Key Parameters of Non-Slip Metal Solutions

| Parameter | Serrated Bar Grating | Perforated Non-Slip Plate | Diamond Safety Grating |

|---|---|---|---|

| Material Options | Carbon Steel, SS304/316, Aluminum | Carbon Steel, SS304/316, Galvanized Steel | Carbon Steel, Aluminum |

| Standard Thickness (mm) | 3mm - 10mm (Bearing Bars) | 2mm - 6mm | 2.5mm - 5mm |

| Load Capacity (kN/m²) | Up to 90 kN/m² (Span dependent) | Up to 25 kN/m² | Up to 30 kN/m² |

| Slip Resistance (Coefficient of Friction) | > 0.8 (Dry), > 0.6 (Wet) | > 0.9 (Dry), > 0.7 (Wet/Oily) | > 0.85 (Dry), > 0.65 (Wet) |

| Corrosion Resistance | Excellent (Galvanized/SS) | Very Good (Galvanized/SS) | Good (Galvanized/Aluminum) |

| Drainage Performance | Excellent (Open Mesh) | Good (Perforations) | Moderate (Small Openings) |

These values represent typical performance under controlled conditions. Actual field performance can vary based on specific environmental factors and maintenance regimes. The selection of the appropriate non slip floor plate or non slip metal grating should always be guided by a thorough assessment of the operational environment, including expected load, exposure to chemicals, and pedestrian/vehicular traffic volume. This ensures optimal safety and longevity from your industrial non barbed wire solution, maximizing its return on investment.

Applications, Advantages, and Customization Capabilities

The versatility and robust nature of high-performance metal grating and floor plates make them indispensable across a spectrum of industrial sectors. From the petrochemical industry, where resistance to corrosive chemicals and extreme temperatures is paramount, to metallurgy where heavy loads and abrasive conditions are common, and in water treatment facilities requiring superior anti-corrosion properties and excellent drainage, these solutions provide critical safety and operational advantages. Their inherent design as non barbed wire systems ensures that personnel can move safely without risk of cuts or snags, a crucial factor in active industrial settings. This commitment to safety is a hallmark of truly advanced non barbed wire products, offering peace of mind to facility managers.

- Enhanced Safety: Superior slip resistance, even in the presence of water, oil, or grease, drastically reduces the risk of slips, trips, and falls.

- Durability & Longevity: High-grade materials and advanced manufacturing ensure extended product lifespan, reducing replacement frequency and associated costs.

- Corrosion Resistance: Options like galvanized steel or stainless steel offer excellent protection against various corrosive agents, crucial for chemical plants and offshore platforms.

- High Load-Bearing Capacity: Engineered to withstand significant static and dynamic loads, making them suitable for heavy machinery areas and high-traffic zones.

- Maintenance Efficiency: Easy to clean and inspect, these surfaces minimize maintenance downtime and simplify operational upkeep.

Beyond standard offerings, leading manufacturers provide extensive customization options. This includes tailored dimensions, specific material grades, unique non-slip patterns, and integrated components for complex installations. Whether it's a specialized industrial walkway, a custom-designed non slip floor plate for a machinery platform, or bespoke stair treads for an access tower, bespoke solutions ensure optimal fit, performance, and compliance with project-specific regulations. Our engineers collaborate closely with clients from conceptualization to deployment, ensuring that every solution, including specific non barbed wire variants, is optimized for the unique challenges of their operational environment.

Ensuring Trust: Certifications, Warranty, and Client Success

Trust is paramount in the B2B sector, especially concerning safety-critical infrastructure. Our commitment to quality is validated through adherence to international standards and certifications. We hold ISO 9001:2015 certification for quality management systems, ensuring consistent product quality from design to delivery. Our products meet or exceed relevant ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute) standards for material strength and grating performance. Furthermore, internal testing protocols, including rigorous load tests and slip resistance evaluations (e.g., using the British Pendulum Test or tribometer), consistently demonstrate the superior performance of our non slip metal grating and stair treads, reflecting their reliability as a true non barbed wire solution.

Our confidence in our product quality is reflected in our comprehensive warranty policies, typically ranging from 5 to 10 years, covering material defects and manufacturing flaws. This provides our clients with long-term peace of mind regarding their investment in non barbed wire industrial solutions. We pride ourselves on transparent delivery timelines, with standard orders typically processed and shipped within 3-4 weeks, while complex custom solutions may require 6-8 weeks, depending on design complexity and material availability. Our dedicated customer support team offers end-to-end assistance, from initial consultation and technical specifications review to post-installation support and maintenance advice. Feedback from clients in the power generation and chemical processing sectors consistently highlights the durability and enhanced safety our products bring to their operational sites, often citing a significant reduction in slip-related incidents since implementation.

Frequently Asked Questions (FAQs) about Non-Slip Metal Solutions

Q1: What is the primary difference between traditional grating and a non barbed wire non-slip solution?

Traditional gratings may offer basic load support, but a non barbed wire non-slip solution, in the context of industrial surfaces, specifically refers to metal gratings and plates engineered with specialized surface profiles (e.g., serrations, perforations, or embossed patterns) to significantly enhance the coefficient of friction, thereby preventing slips, particularly in wet, oily, or icy conditions, without having any sharp or aggressive elements found in barbed wire.

Q2: How do you determine the correct material for a specific application?

Material selection is critical and depends on environmental factors such as exposure to corrosive chemicals, extreme temperatures, required load capacity, and aesthetic considerations. For highly corrosive environments, stainless steel (e.g., SS316L) is recommended. For general industrial use with good corrosion protection, hot-dip galvanized carbon steel is a cost-effective choice. Aluminum is preferred where weight is a critical factor.

Q3: Can these non slip metal grating products be custom fabricated to specific dimensions?

Absolutely. Custom fabrication is a core service. We can design and manufacture non slip floor plate, grating, and stair tread solutions to precise dimensions, shapes, and load requirements, including integration with existing structures. Our engineering team uses advanced CAD software to ensure perfect fit and functionality for unique project needs.

Q4: What is the expected lead time for order delivery?

Standard product orders typically have a lead time of 3-4 weeks from order confirmation to dispatch. For highly customized or large-volume projects, lead times may extend to 6-8 weeks or more, depending on complexity and material sourcing. We maintain transparent communication throughout the production process to keep clients informed.

Conclusion: Investing in Superior Industrial Safety and Performance

The demand for high load-bearing capacity, high safety non slip metal walkway stair treads, and robust non slip metal grating continues to grow as industries prioritize worker safety and operational longevity. By moving beyond traditional solutions to embrace advanced engineering and materials, businesses can significantly mitigate risks, reduce maintenance costs, and enhance overall productivity. The emphasis on products that function as non barbed wire surfaces—meaning safe, smooth, yet highly friction-resistant—marks a pivotal shift towards human-centric industrial design. Partnering with a manufacturer that combines technical expertise, stringent quality control, and a commitment to customized solutions ensures that your industrial infrastructure is not just compliant, but truly optimized for peak performance and unwavering safety. This holistic approach ensures long-term value from your investment in advanced non barbed wire solutions.

References

- American Society for Testing and Materials (ASTM) Standards for Steel and Galvanizing.

- International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

- National Association of Architectural Metal Manufacturers (NAAMM) MBG 531-15: Metal Bar Grating Manual.

- Occupational Safety and Health Administration (OSHA) Walking-Working Surfaces Guidelines.