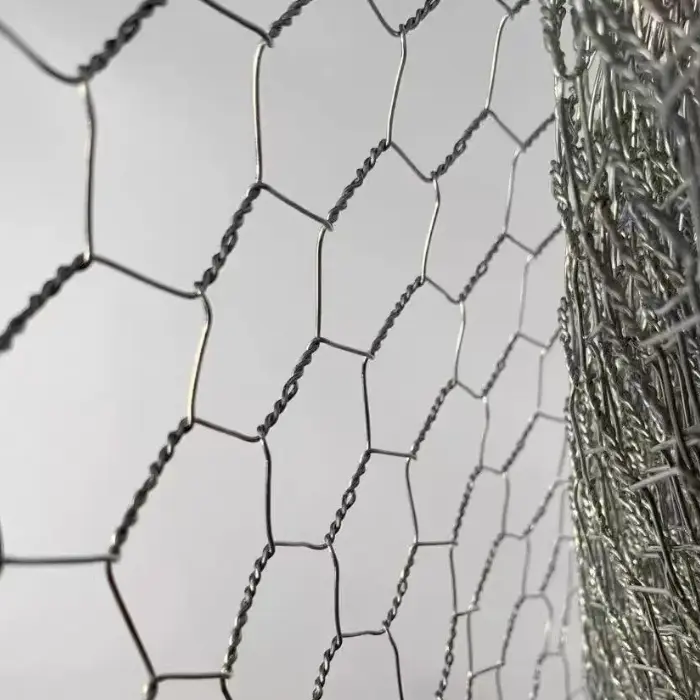

Steel Grate is a robust and highly functional architectural and industrial component made from steel bars or plates welded together to form an open grid pattern. Renowned for its exceptional load-bearing capacity and slip-resistant surface, it is extensively used in flooring, walkways, drainage covers, and industrial platforms. The open design allows for efficient drainage, ventilation, and light penetration while maintaining structural integrity under heavy loads.

Beyond industrial applications, steel grates are employed in urban design for bridges, stair treads, and decorative facades, combining practicality with a modern aesthetic. Low maintenance and long-lasting, they provide a safe, stable surface in high-traffic areas. Whether for functional or architectural purposes, steel grates deliver an optimal balance of strength, safety, and versatility in diverse engineering and construction projects.

Galvanized vs Stainless Steel Grating

Galvanized steel grating features a zinc-coated surface that provides cost-effective corrosion resistance, making it ideal for industrial walkways, platforms, and outdoor applications exposed to moisture or mild chemicals. While durable, it may require maintenance in highly corrosive environments like coastal areas.

Stainless steel grating, made from 304 or 316-grade steel, offers superior corrosion resistance, especially in chemical plants, marine settings, or food processing facilities. Though more expensive, its longevity and minimal upkeep justify the investment in harsh conditions. The choice depends on budget, environmental exposure, and project lifespan.

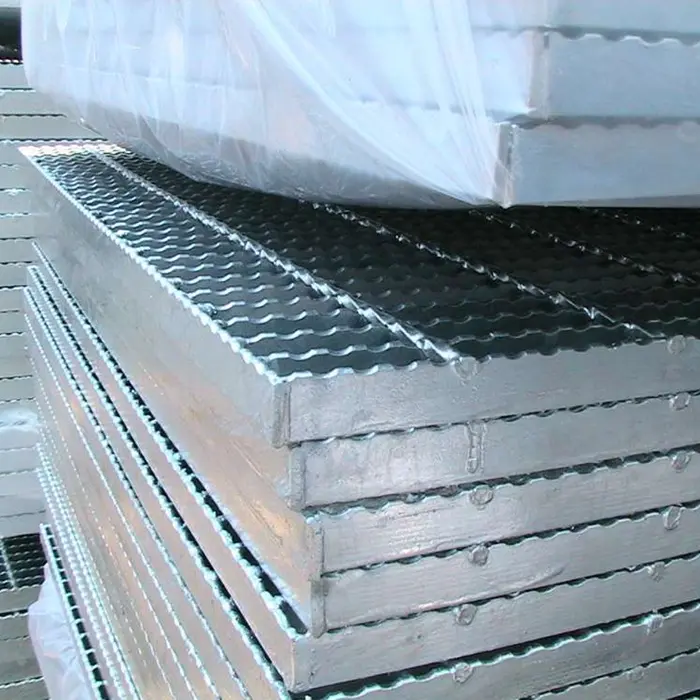

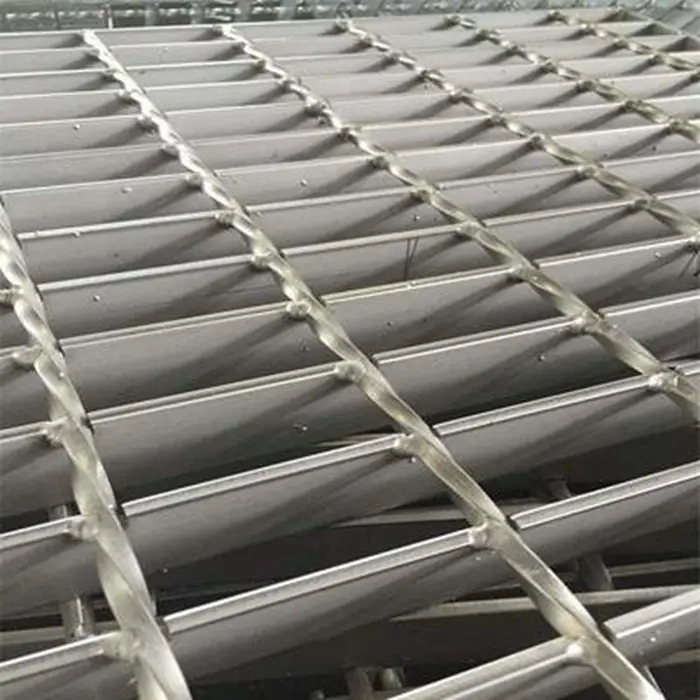

Serrated vs Plain Steel Grating: Which One to Choose?

Serrated steel grating has tooth-like projections on its surface, significantly enhancing slip resistance for oil rigs, ramps, or wet industrial areas. However, the textured surface can accumulate debris and may not suit shoe-sensitive environments.

Plain steel grating, with a smooth surface, is easier to clean and ideal for dry settings like pedestrian walkways or architectural designs where aesthetics matter. While less slip-resistant, it offers better underfoot comfort.

Choose serrated for safety-critical, high-risk zones and plain for general-purpose or visually sensitive applications. The decision hinges on traction needs, maintenance, and usage context.