Security Enhancement in Industrial Facilities

Preventing Unauthorized Access

Factories and industrial zones often house expensive machinery, raw materials, and proprietary technology, making them prime targets for theft and sabotage. Metal mesh fencing acts as a first line of defense, deterring intruders with its robust construction.

High-Strength Barriers: Made from galvanized steel or aluminum, metal mesh fences resist cutting and climbing attempts, unlike chain-link fences, which can be easily breached.

Anti-Scalping Features: Some designs incorporate curved or barbed tops to prevent climbing, ensuring that unauthorized individuals cannot easily scale the fence.

Integration with Surveillance Systems: Metal mesh fences can be fitted with motion sensors, CCTV cameras, and alarm systems, creating a smart perimeter security network that alerts security personnel to breaches.

Controlled Entry and Exit Points

Industrial facilities require strict access control to regulate the movement of personnel and vehicles. Metal mesh fencing supports this by:

Supporting Automated Gates: Heavy-duty metal mesh panels can be integrated with biometric scanners, RFID entry systems, and boom barriers to ensure only authorized personnel enter.

Segregating High-Risk Zones: Hazardous areas, such as chemical storage or high-voltage equipment zones, can be securely enclosed to prevent accidental entry.

Safety and Hazard Mitigation

Protecting Workers and Equipment

Industrial environments often involve heavy machinery, moving vehicles, and hazardous materials. Metal mesh fencing enhances workplace safety by:

Creating Physical Barriers: Prevents accidental entry into dangerous zones (e.g., construction sites, loading docks, and machinery operation areas).

Reducing Flying Debris Risks: In manufacturing plants where metal cutting or welding occurs, mesh fences act as spark shields, containing hazardous fragments.

Improving Visibility: Unlike solid walls, metal mesh allows supervisors to monitor activities without obstructing sightlines, enabling quick response to emergencies.

Fire and Explosion Containment

In industries dealing with flammable substances (e.g., oil refineries, chemical plants), metal mesh fencing can be fire-resistant, helping to:

Slow the spread of flames by acting as a heat barrier.

Prevent shrapnel dispersal in case of explosions.

Perimeter Control and Traffic Management

Defining Boundaries and Restricted Zones

Large industrial complexes require clear demarcation between public and restricted areas. Metal mesh fencing provides:

Clear Zone Separation: Differentiates between employee parking, delivery zones, and operational areas.

Vehicle Traffic Regulation: Guides trucks and forklifts along designated pathways, reducing collision risks.

Deterring Wildlife and Environmental Hazards

In outdoor industrial sites (e.g., mining, power plants), metal mesh fencing prevents:

Animal intrusions that could damage equipment or cause accidents.

Unauthorized dumping or trespassing in remote facilities.

Durability and Low Maintenance

Weather and Corrosion Resistance

Industrial environments expose fencing to harsh conditions, including:

Extreme temperatures (from freezing cold to intense heat).

Chemical exposure (in plants dealing with acids, solvents, or saltwater environments).

Metal mesh fences made from galvanized steel or powder-coated aluminum resist rust and degradation, ensuring long-term reliability with minimal upkeep.

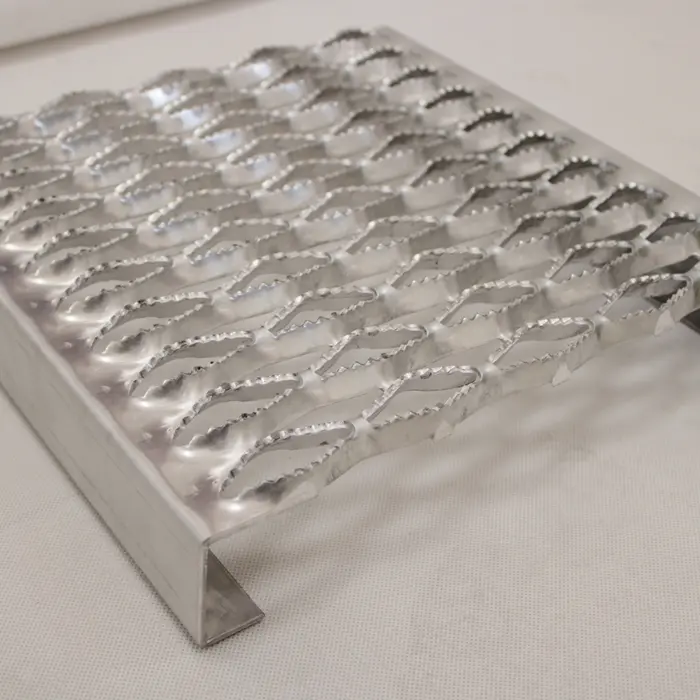

Vandalism and Impact Resistance

Unlike wooden or plastic barriers, metal mesh fences withstand:

Intentional damage (hammering, cutting attempts).

Accidental impacts from vehicles or falling debris.

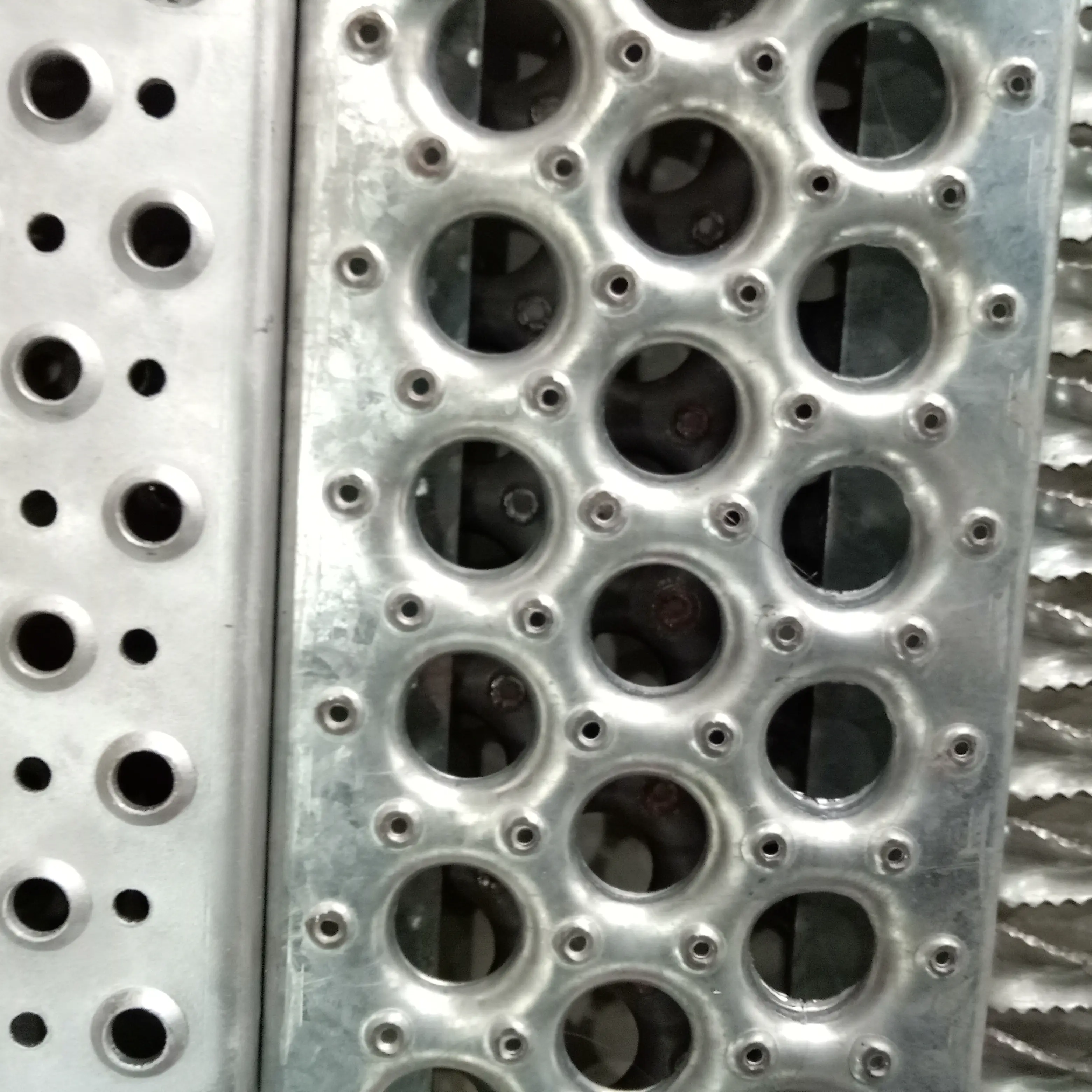

Modular and Adaptable Designs

Factories can customize metal mesh fencing based on needs, including:

Height adjustments for varying security levels.

Mesh density changes (smaller gaps for higher security, larger gaps for ventilation).

Aesthetic integration (powder-coated colors to match corporate branding).

Metal mesh fencing has become an indispensable component of industrial security and safety strategies. Its ability to deter intruders, enhance workplace safety, regulate traffic, and withstand harsh conditions makes it a superior choice for factories, warehouses, and industrial parks.

As industries continue to evolve—incorporating automation, IoT-enabled security, and stricter safety regulations—metal mesh fencing will remain a critical infrastructure element, adapting to new challenges while ensuring robust protection for assets and personnel.

Investing in high-quality metal mesh fencing is not just about erecting a barrier; it’s about building a smarter, safer, and more efficient industrial environment.