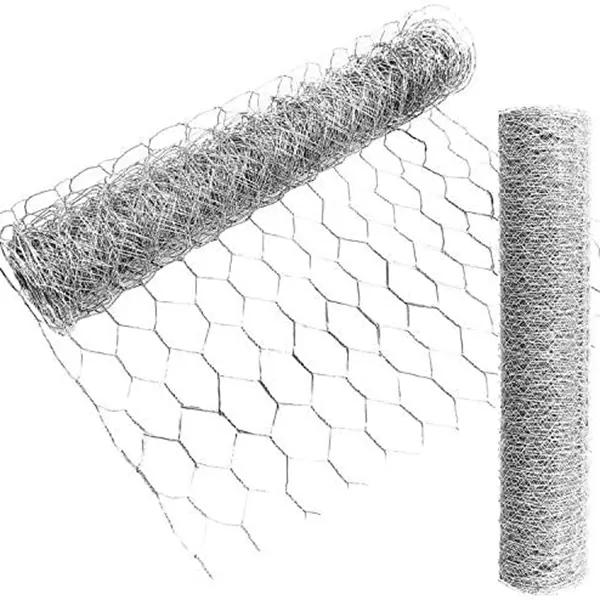

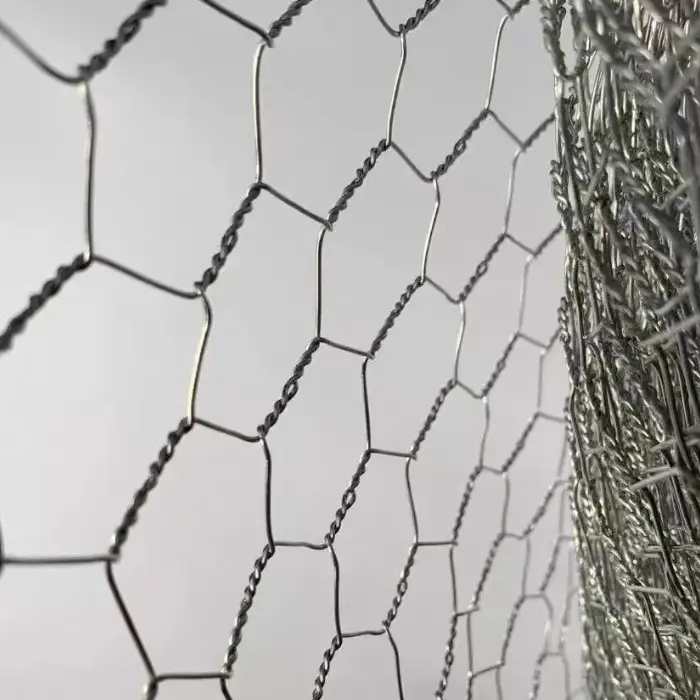

A woven mesh fence is a durable and flexible fencing solution constructed by interlocking vertical and horizontal wires in a continuous weaving pattern, creating a strong yet adaptable barrier. Unlike welded mesh, its knitted design allows slight movement, making it ideal for agricultural, residential, and light industrial applications where tension absorption is needed.

Commonly made from galvanized or PVC-coated steel, woven mesh resists rust and weathering, ensuring longevity in outdoor environments. Its tight grid patterns, such as 2x3-inch or 4x4-inch openings, effectively contain livestock (e.g., sheep, goats) while keeping predators out. The fence’s natural flexibility accommodates uneven terrain, preventing sagging or damage from animal pressure.

What Are the Advantages of Woven Wire Fence?

Woven wire fencing offers exceptional flexibility and durability, making it ideal for agricultural and containment applications. Its interlocking design allows the fence to absorb impact without breaking, making it perfect for livestock enclosures where animals may lean or push against it. Unlike rigid fencing, woven wire can conform to uneven terrain, maintaining security on slopes or rough ground.

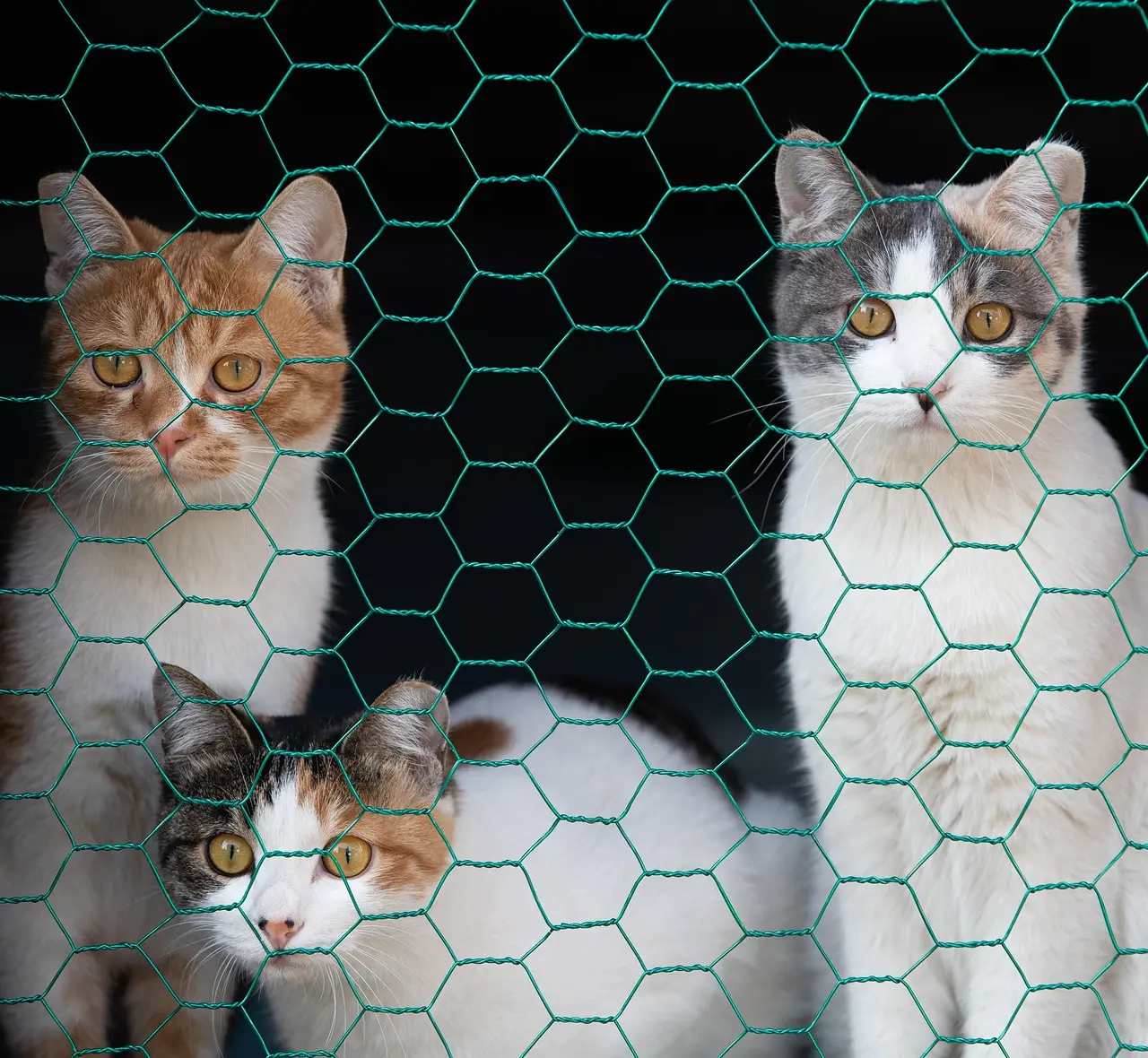

The tight mesh patterns prevent small animals from escaping while keeping predators out, providing reliable protection for poultry, gardens, and pastures. Additionally, woven wire fences are long-lasting, often constructed from galvanized or PVC-coated steel to resist rust and weathering. Their low-maintenance nature and cost-effectiveness make them a preferred choice for farmers and ranchers seeking a sturdy yet adaptable fencing solution.

What's Better, Woven or Welded Wire Fencing?

The choice between woven and welded wire fencing depends on the specific application. Woven wire excels in agricultural settings due to its flexibility, impact resistance, and ability to adapt to uneven ground. It’s ideal for livestock, deer fencing, and areas requiring durability against animal pressure.

On the other hand, welded wire fencing provides superior rigidity and security, making it better for perimeter protection, cages, and high-traffic areas. Its fixed grid pattern resists bending and is harder to breach, which is why it’s commonly used in construction, security fencing, and industrial sites.

For heavy-duty containment, woven wire is often preferred, while security and structural applications favor welded wire. The best option depends on whether flexibility or strength is the priority.