Welding shinge yana nufin tsarin gini shingen karfe using welding techniques to join individual components, such as rails, posts, and panels. This method ensures a strong, durable, and long-lasting structure, making it ideal for security, privacy, and boundary demarcation. Typically made from materials like steel, iron, or aluminum, welded fences are resistant to weathering, corrosion, and physical impact, especially when treated with protective coatings like galvanization or powder coating. Their robust construction and adaptability make them a preferred choice for perimeter fencing solutions in both commercial and industrial settings.

Compared to prefabricated or bolted fences, high security perimeter fencing like welded fence provides superior strength and stability, making them suitable for high-security areas like prisons, military sites, or industrial facilities. Additionally, their aesthetic appeal allows for decorative designs, blending functionality with visual appeal. Proper installation and maintenance ensure that perimeter security fence solutions remain robust and effective for decades, offering long-term reliability and peace of mind.

Har yaushe Za'a Daukar Katangar Waya mai Weld?

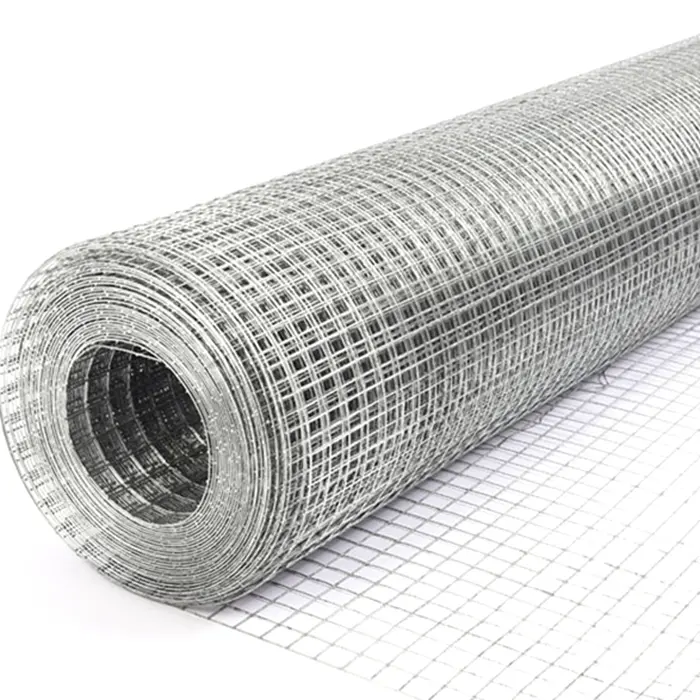

A welded wire fence typically lasts between 15 to 30 years, depending on material quality, environmental conditions, and maintenance. Fences made from galvanized steel tend to last the longest (20-30 years) due to their rust-resistant coating, while non-galvanized or lower-quality wire may deteriorate in 10-15 years. Powder-coated fences offer additional protection against corrosion and UV damage, extending their lifespan further. For enhanced durability and corrosion resistance, consider using stainless steel welded wire mesh panels, which provide superior strength and longevity even in harsh environments.

Harsh weather, such as heavy rain, snow, or coastal salt air, can accelerate rust and weaken the fence over time. Regular inspections for rust, loose welds, or bent wires help prolong its durability. If damage occurs, prompt repairs—such as applying rust-resistant paint or replacing broken sections—can prevent further degradation. Proper installation, including secure posts and tensioning, also plays a key role in longevity. For applications requiring lightweight yet durable fencing, PVC weld mesh offers an excellent alternative, combining flexibility with resistance to environmental wear. Overall, with good maintenance and the right material choice, a welded wire fence can remain functional and sturdy for decades.

Ta Yaya Zaku Rike shingen Waya mai Weld?

Don kiyaye shingen shinge mai welded, shigarwa mai dacewa da gyare-gyare na lokaci-lokaci suna da mahimmanci. Fara da tabbatar da kafaffen ginshiƙai masu ƙarfi (karfe ko itacen da aka gyara) ba su wuce ƙafa 8-10 ba tsakanin su don hana sagging. Mikewa ragamar da ƙarfi yayin shigarwa ta amfani da shimfidar shinge ko kayan aiki tare yana taimakawa kawar da rashin ƙarfi.

Bayan lokaci, yanayi da asarar tashin hankali na iya haifar da shingen shinge. Sake ƙulla waya tare da igiyoyin tashin hankali ko shirye-shiryen waya na iya dawo da ƙarfi. Ƙara layin goyan baya a kwance tsakanin posts kuma yana taimakawa rarraba tashin hankali a ko'ina. Don ƙarin kwanciyar hankali, kiyaye ƙasan shingen tare da gungumen azaba na ƙasa ko waya ta tashin hankali don hana dabbobi ko tarkace turawa waje. Bincike na yau da kullum da ƙananan gyare-gyare suna tabbatar da shingen ya kasance mai kyau da tsaro na shekaru.