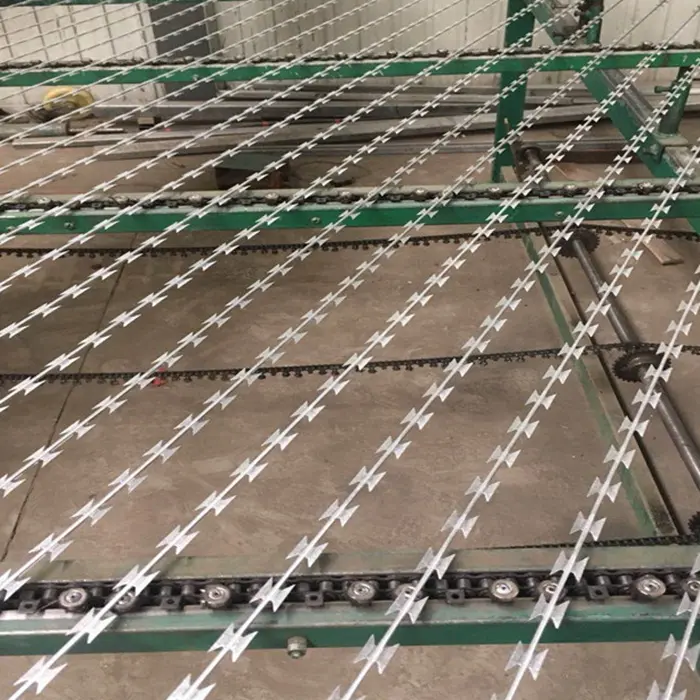

Concertina Razor Wire is a high-security coiled fencing system designed for maximum intrusion deterrence through its formidable spiral structure lined with razor-sharp blades. Unlike static razor wire, its expandable spring-like coils can be deployed rapidly as standalone barriers or mounted atop walls/fences, creating instant 3D obstacles with overlapping layers of cutting edges. The coiled design allows flexibility in configuration—stretched horizontally for perimeter lines or stacked vertically for anti-scaling protection.

Manufactured from galvanized or stainless steel with clipped blade patterns, concertina wire delivers extreme penetration resistance while withstanding weather corrosion. Its overlapping coils form dense, interlocking barriers that are virtually impossible to cross without specialized tools, making it ideal for military zones, border security, and high-risk facilities. The blades' multidirectional arrangement ensures contact injuries regardless of approach angles.

What is the Difference Between Razor Wire and Concertina Wire?

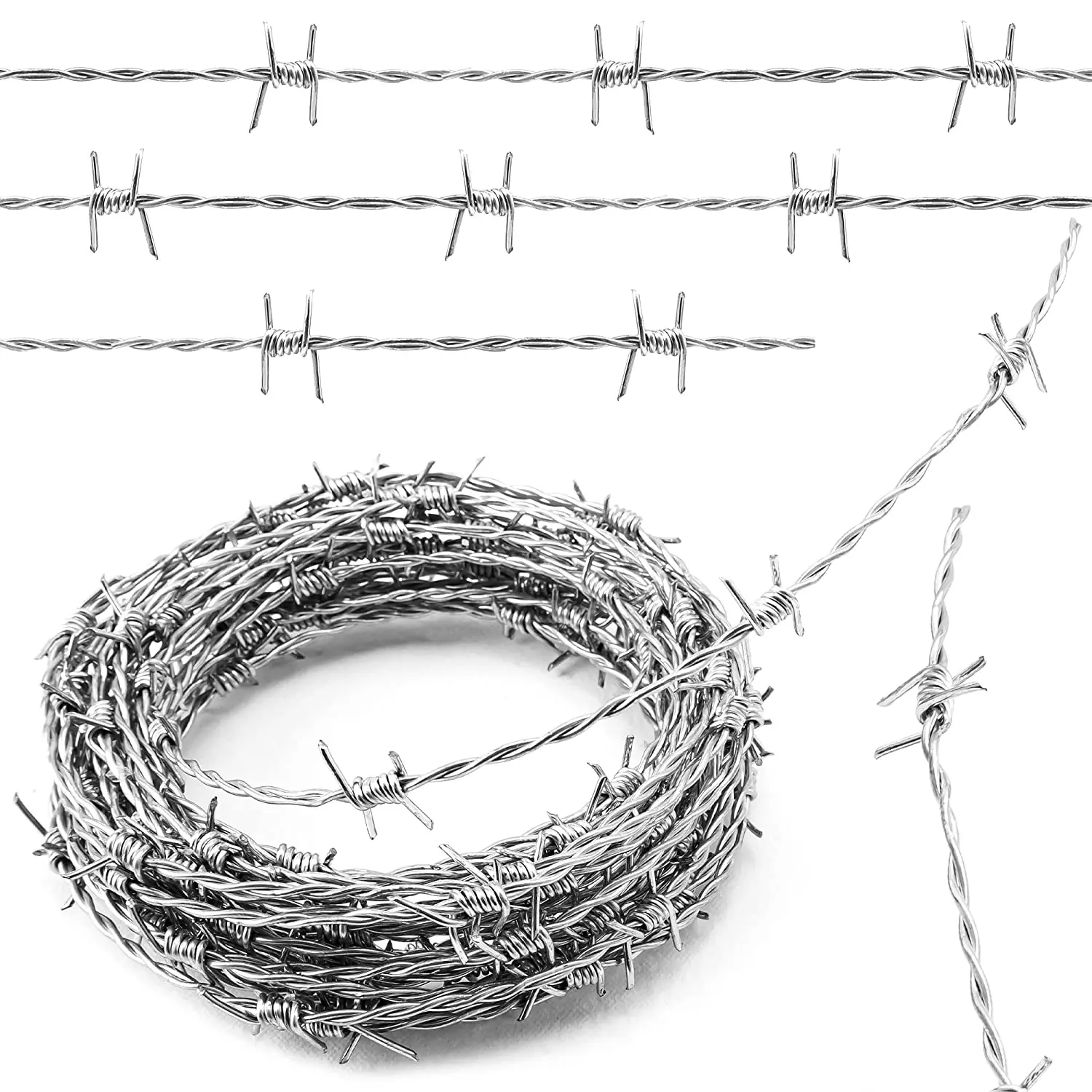

Razor wire and concertina wire are both high-security barriers, but they differ in design and deployment. Razor wire consists of sharp, blade-like metal strips mounted on a central wire, creating a linear deterrent. It is often used as a topping for fences or walls to prevent climbing.

Concertina wire, a subtype of razor wire, is coiled into large, expandable loops that can be deployed rapidly. Unlike straight razor wire, concertina wire forms three-dimensional barriers that are difficult to compress or cross. It is commonly used in military zones, prisons, and temporary security perimeters due to its quick installation and formidable obstacle effect.

While all concertina wire is razor wire, not all razor wire is concertina—the key distinction lies in the coiled, spring-like form of concertina versions.

Advantages of Hot-Dip Galvanized Concertina Razor Wire

Hot-dip galvanized concertina razor wire offers exceptional durability and corrosion resistance, making it ideal for long-term outdoor security. The zinc coating applied through hot-dipping creates a protective layer that prevents rust, even in coastal or industrial environments with high humidity and salt exposure.

This type of razor wire maintains sharpness and structural integrity for decades, requiring minimal maintenance. The galvanization process also strengthens the steel core, ensuring the concertina coils remain flexible yet resilient under extreme weather conditions.

Additionally, hot-dip galvanized razor wire is cost-effective compared to stainless steel variants, while still providing high-level security. Its weather-resistant properties make it suitable for border fences, prisons, and critical infrastructure, where long-term performance is essential. The combination of anti-corrosion, strength, and low upkeep makes it a top choice for permanent security installations.