Metal Grating is a robust, open-grid structural material widely used in industrial, commercial, and architectural applications. Manufactured by welding or locking intersecting metal bars together, it creates a rigid yet lightweight framework that offers excellent load-bearing capacity, slip resistance, and ventilation. Common steel grate materials include carbon steel, stainless steel, and aluminum, chosen for their strength, corrosion resistance, or aesthetic appeal.

One of the key advantages of metal grating is its versatility. In industrial settings, it serves as walkways, platforms, or drainage covers, providing safe footing while allowing light, air, and liquids to pass through. In architectural designs, square grating can be used for facades, sunscreens, or decorative elements, combining functionality with modern aesthetics. Its durability and low-maintenance properties make it ideal for harsh environments, such as oil refineries, wastewater treatment plants, or outdoor stair treads.

What Does Steel Grating Do?

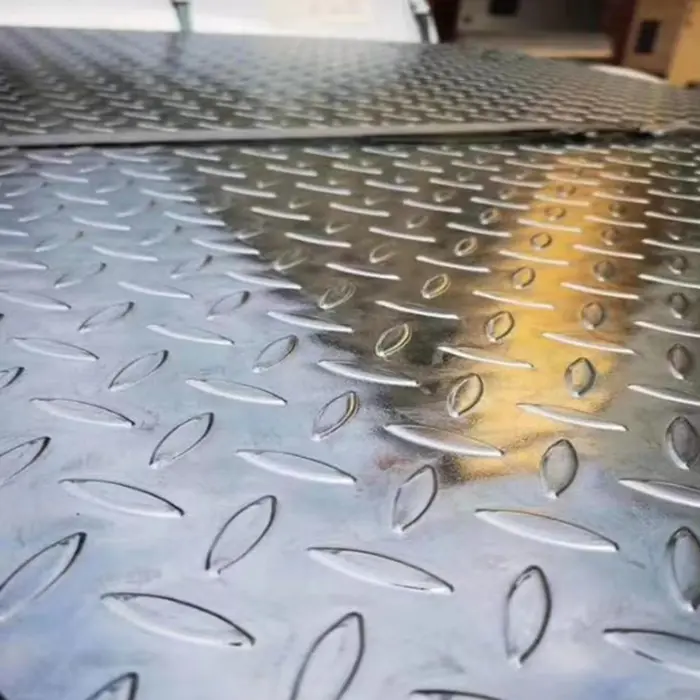

Steel grating is a load-bearing structural material composed of interconnected steel bars, creating an open grid pattern. Its primary function is to provide a secure, durable walking surface that allows light, air, and liquids to pass through while supporting heavy weights. Commonly made from carbon steel, stainless steel, or aluminum, it is used in industrial platforms, stair treads, drainage covers, and mezzanines.

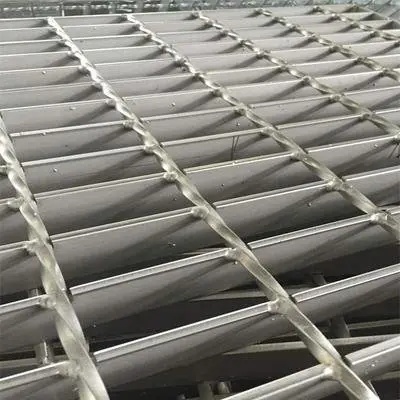

The grating’s design ensures high strength-to-weight ratio, making it ideal for environments requiring ventilation, drainage, or debris management. Its rigid construction resists impact, corrosion, and fire, suitable for oil refineries, factories, and wastewater plants. Custom grating meets the safety and operational demands of various industries thanks to its flexible customization in bar spacing, thickness, and surface treatments.

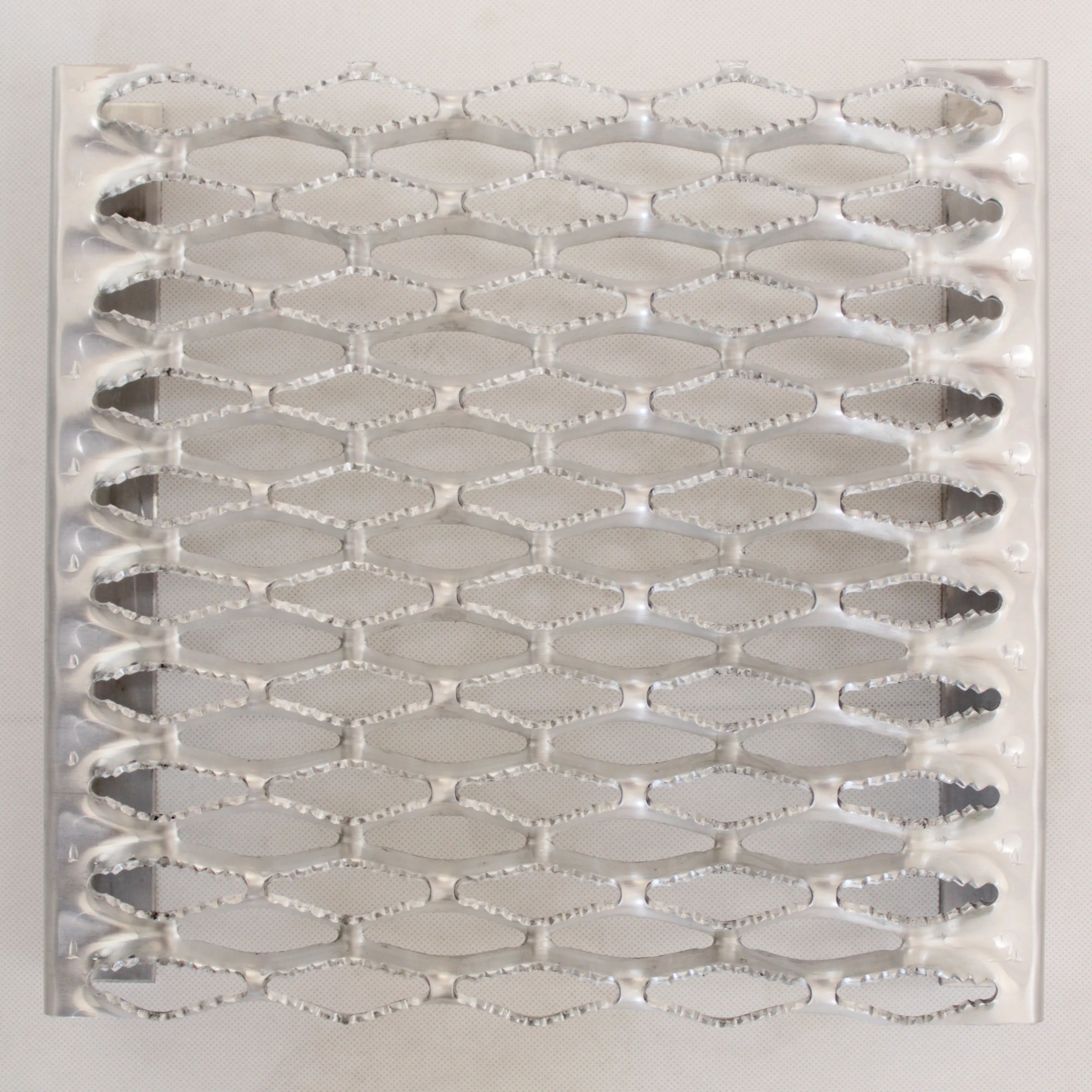

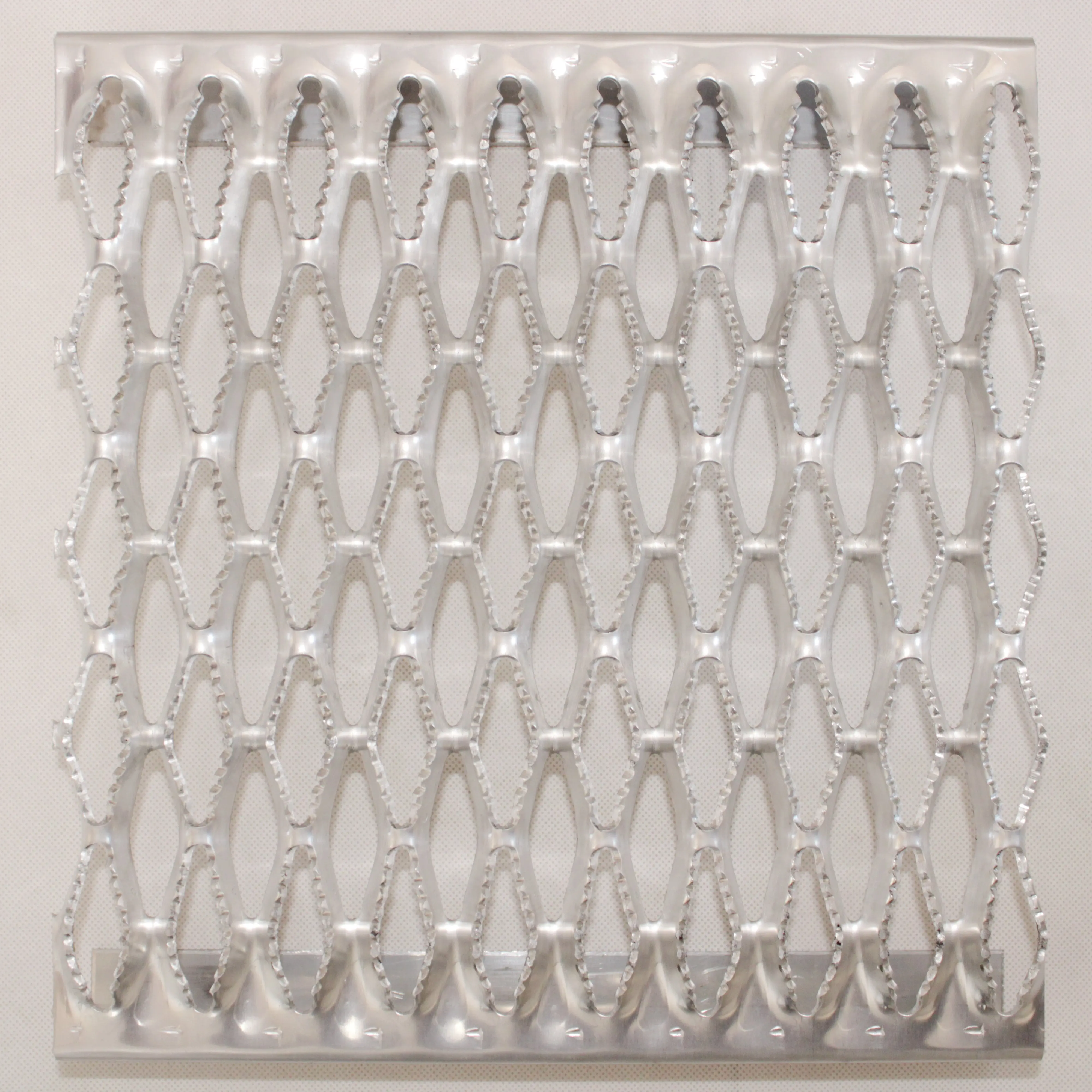

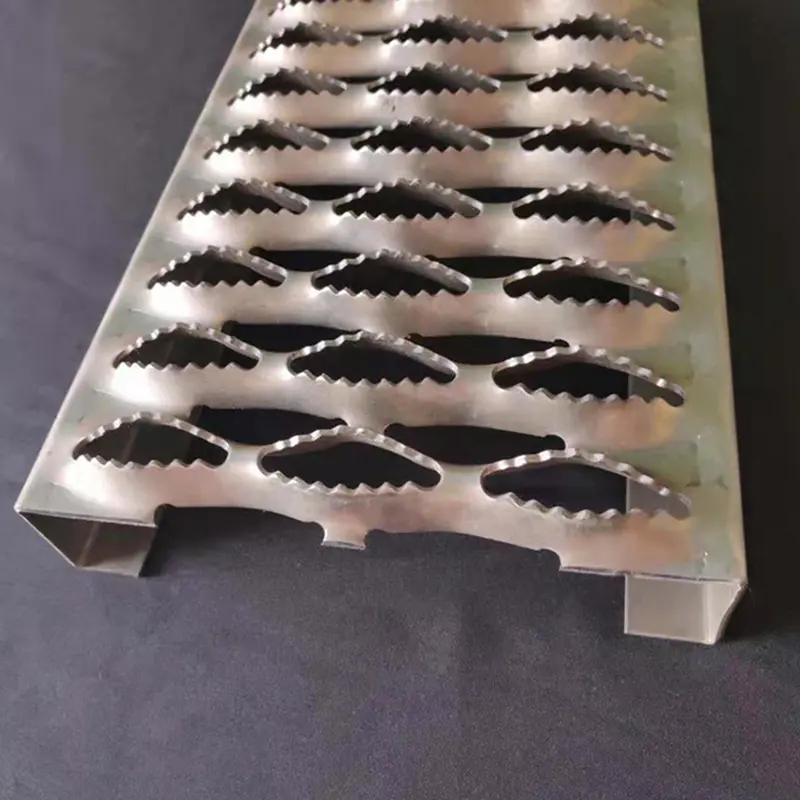

Anti-Slip Metal Grating for Industrial Safety Applications

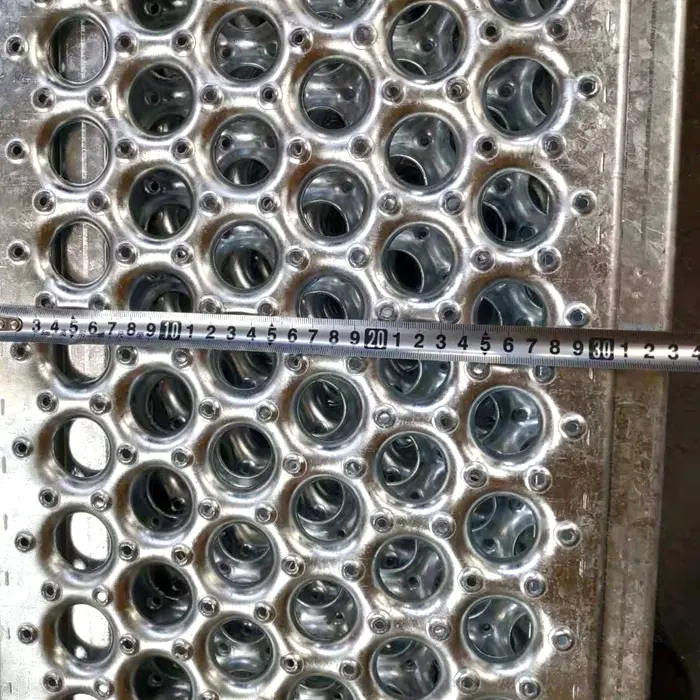

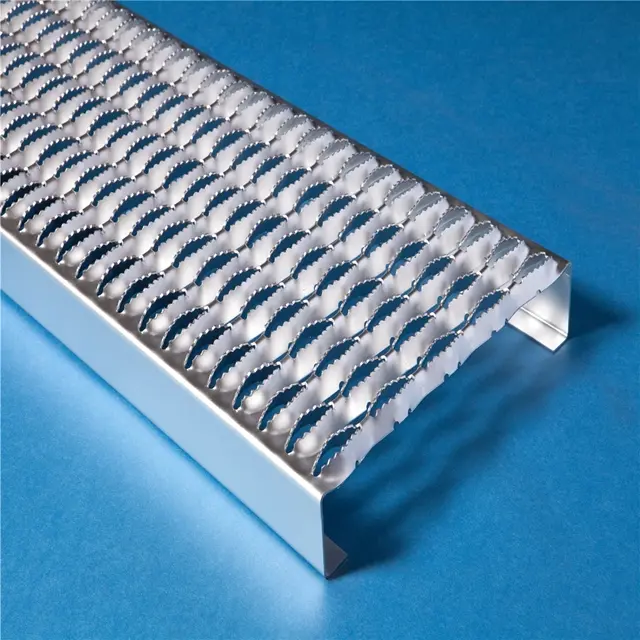

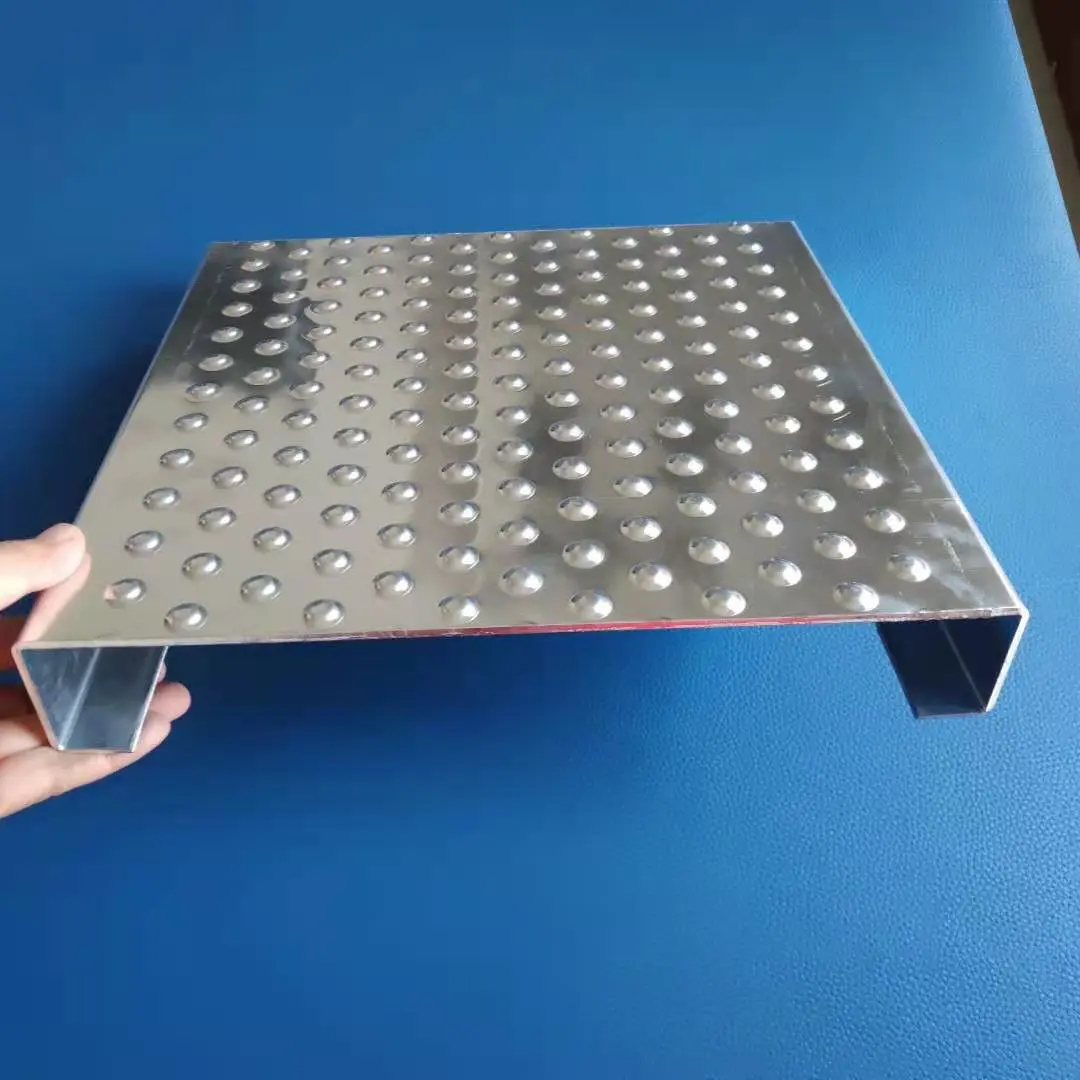

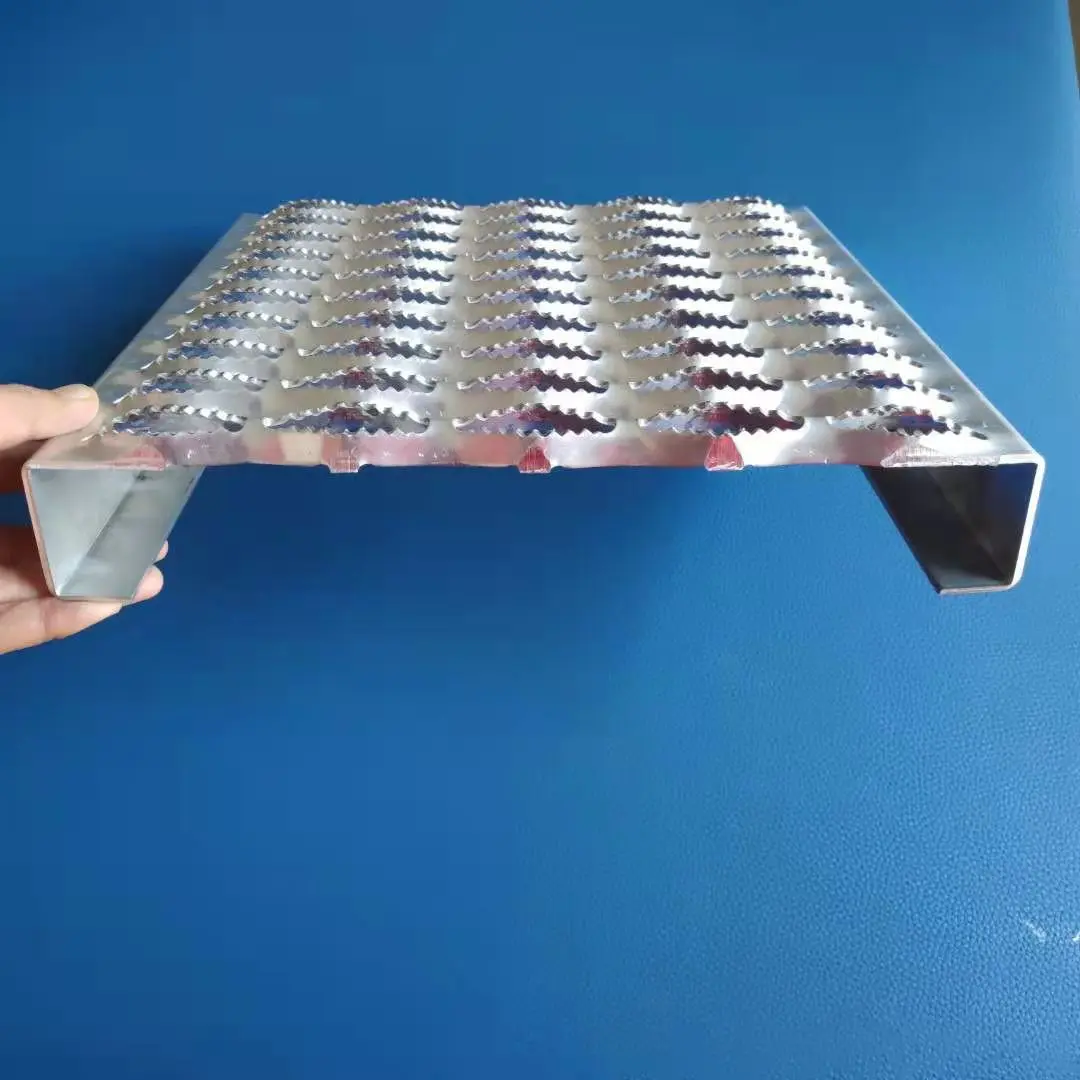

Anti-slip metal grating or perforated anti skid plate incorporates serrated surfaces, grit coatings, or perforated patterns to prevent accidents in wet or oily environments. Used in walkways, offshore platforms, and food processing plants, it reduces fall risks while maintaining drainage and airflow.

Steel grate materials like galvanized steel or serrated aluminum enhance traction and corrosion resistance. The open of grating platform design also minimizes snow, ice, or chemical buildup, ensuring long-term safety. Compliant with OSHA and ISO standards, it is a critical component in high-risk industrial settings where worker safety and durability are paramount.