1. Welding process: "precision splicing" of steel grating

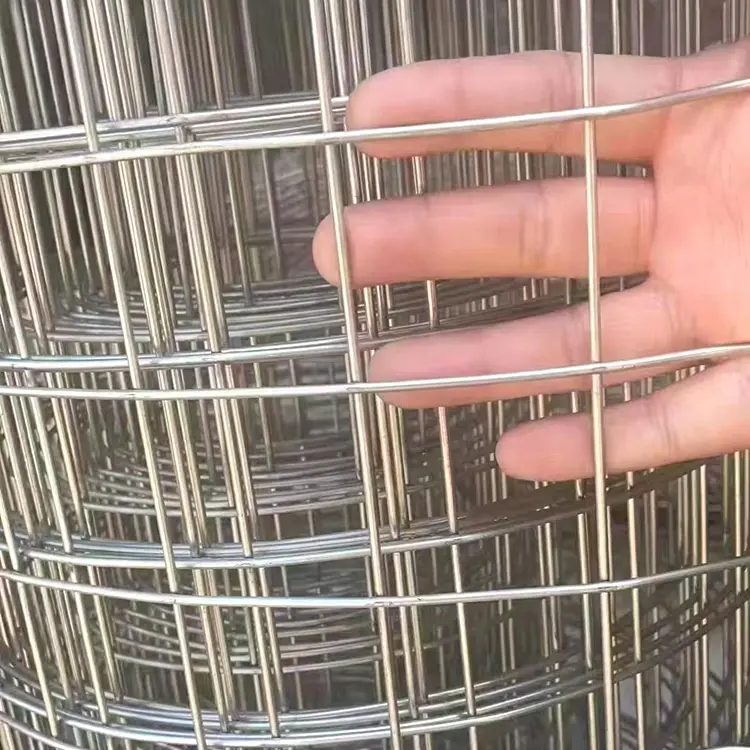

Core logic: welding is the "skeleton construction" of steel grating, which welds flat steel and crossbars into a stable structure.

Process comparison:

Pressure welding: similar to the instant high-temperature welding of "teppanyaki", the nodes are firm but need to prevent overheating and embrittlement.

Press lock process: like "Lego blocks" bite and reinforce, with both shear resistance and fatigue resistance.

Automated welding: robots are like "mechanical embroiderers", and millimeter-level precision improves efficiency and stability.

Quality trap: uneven welding points are easy to become "tofu dregs engineering", and we need to be vigilant about "false welding" and "thermal cracks".

2. Load-bearing capacity: "mechanical balance" of steel grating

Core logic: load-bearing design needs to find the "golden balance point" between material strength, grid density and span.

Key elements:

Material selection: ordinary steel is like "fitness coach" which is strong but afraid of corrosion, and stainless steel is like "special forces" which is durable but expensive.

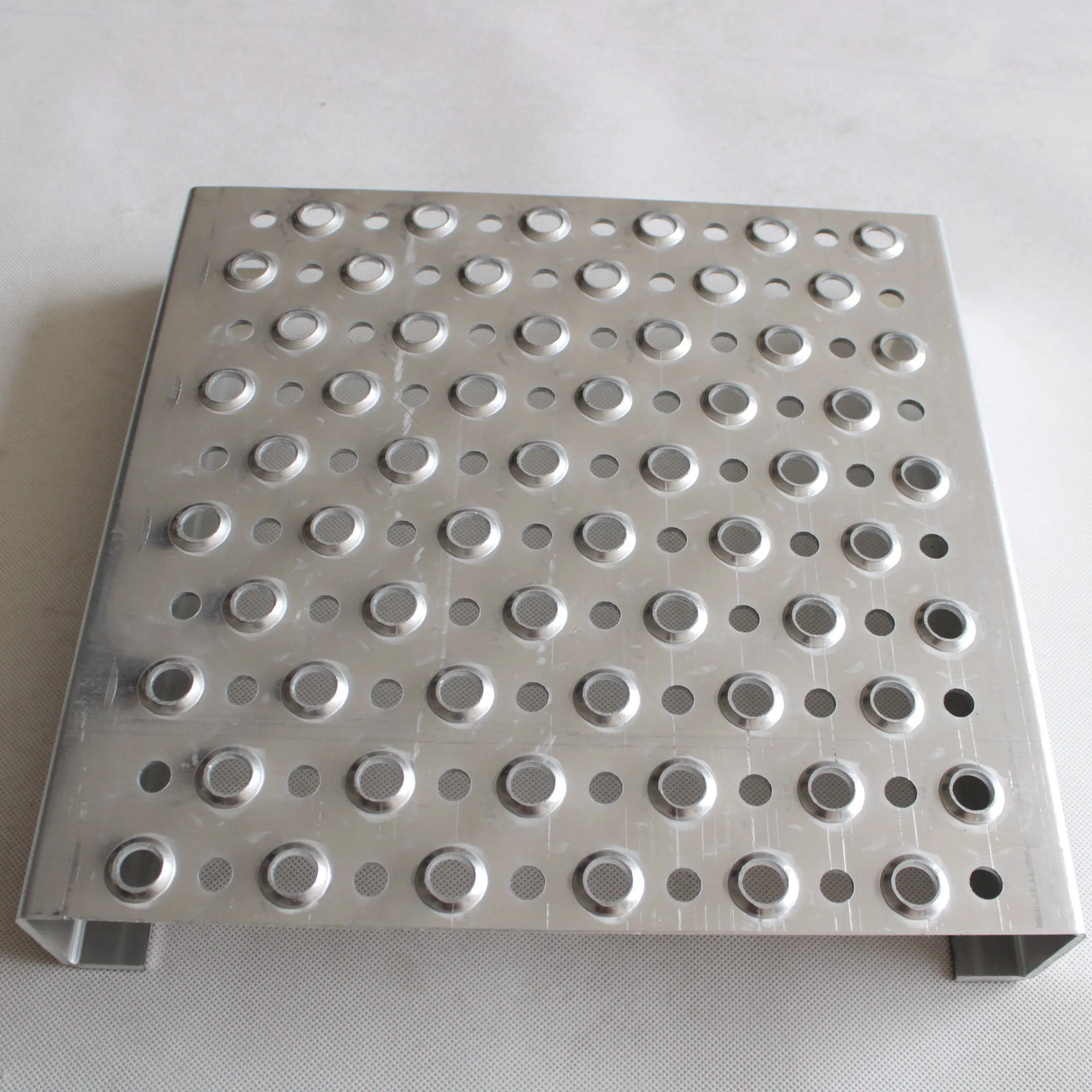

Grid density: Imagine "fishing with a fishing net". The denser the grid, the more stable the load-bearing capacity but the higher the cost.

Span optimization: Long spans need to be "leveraged" (add crossbars) to avoid the "seesaw effect".

Case warning: The steel grating of a chemical plant collapsed because the grid was sparse like a "colander" and the welding point failed like a "broken bone".

3. Corrosion resistance: "environmental defense" of steel grating

Core logic: Corrosion resistance is the "survival armor" of steel grating, which needs to fight against "environmental assassins" such as acid, alkali, moisture, and salt spray.

Defense strategy:

Material upgrade: Stainless steel is like a "golden bell", hot-dip galvanizing is like "rust-proof paint", and coating is like "sunscreen".

Environmental adaptation: Coastal areas need to be "fully armed" (stainless steel + coating), and high temperature environments need "heat-resistant armor" (special alloys).

Invisible enemy: Salt spray is like "invisible acid rain", and the coating thickness needs to be "checked" regularly.