- Introduction to Barbed Wire Tape: Security Innovations and Importance

- Technical Advances and Features of Modern Barbed Tape Concertina

- Manufacturer Comparison: Evaluating Key Competitors

- Customization Solutions: Tailoring Concertina Razor Barbed Tape

- Application Scenarios: Real-World Use Cases

- Market Trends, Data Insights, and Industry Challenges

- Conclusion: The Future of Barbed Wire Tape in Perimeter Security

(barbed wire tape)

Introduction to Barbed Wire Tape: Security Innovations and Importance

Among modern security deterrents, barbed wire tape

stands out as a crucial element in perimeter protection systems. Over the last decade, increased concerns over facility intrusion, asset theft, and public safety have accelerated innovation in security fencing materials. According to a 2023 industry survey by Global Security Insights, over 62% of critical infrastructure sites now deploy some variant of barbed tape concertina. This demand is driven by the necessity for robust, low-maintenance barriers that deter both opportunistic and premeditated breaches. The synergy of physical deterrence and psychological impact provided by concertina razor barbed tape makes it the product of choice for government installations, correctional institutions, private premises, and military bases worldwide.

Technical Advances and Features of Modern Barbed Tape Concertina

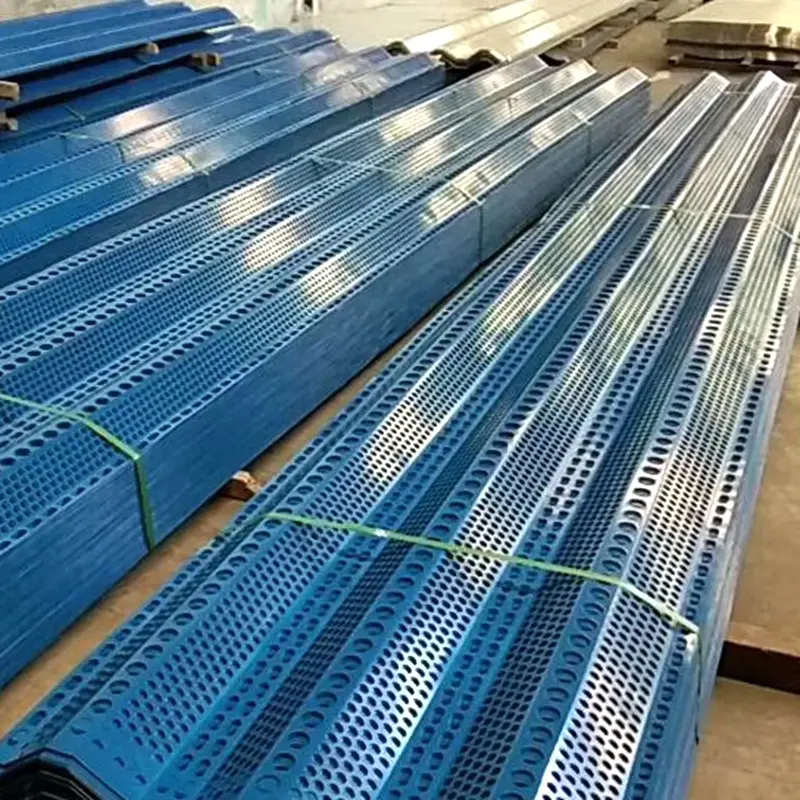

The evolution of barbed tape concertina technology has introduced several advancements aimed at maximizing security while minimizing maintenance and installation time. Early forms, characterized by simple wire with sporadic barbs, have given way to high-tensile galvanized cores wrapped with razor-sharp blades. These technological shifts offer increased strength-to-weight ratios, enhanced corrosion resistance, and improved durability under extreme environmental conditions.

Today's top-performing products utilize stainless steel or zinc-coated steel blades capable of withstanding over 3000 hours in ASTM B117 salt fog testing, ensuring long-term resilience even in coastal or industrial settings. Cutting-edge manufacturing also allows for variable coil diameters, barb spacing, and blade profiles—enabling tailored security responses to specific threat levels. These technical enhancements not only deter unauthorized intruders physically but also serve as an unmistakable visual warning, reducing attempted breaches by up to 78% according to the European Perimeter Safety Association's 2022 report.

Additionally, the integration of anti-climb and anti-cut properties, thanks to innovative interlocking clips and machine-stamped razor blades, increases the level of deterrence, making penetration attempts both hazardous and time-consuming. This is further supported by rigorous quality control protocols, including tensile strength testing, blade sharpness analysis, and UV exposure simulation, which collectively assure security managers of product reliability throughout the operational lifecycle.

Manufacturer Comparison: Evaluating Key Competitors

Selecting the appropriate manufacturer is paramount when optimizing security investment. Differences in raw material sourcing, quality assurance processes, supply chain consistency, and innovation pipelines all directly affect performance in the field. The table below outlines a comparative analysis of three leading global suppliers of concertina razor barbed tape, focusing on critical technical and commercial attributes:

| Brand | Core Material | Blade Material | Coil Diameter Range | Barb Length (mm) | Corrosion Resistance | Annual Output (km) | Lead Time (days) |

|---|---|---|---|---|---|---|---|

| SecureLine | High-tensile Galvanized Steel | Stainless Steel (SS304) | 450-980 | 22 | ISO 9227 tested (3000h) | 12,000 | 14 |

| FortiGuard | Galvanized Steel | Galvanized Steel | 500-900 | 18 | ISO 9227 tested (1500h) | 8,700 | 11 |

| UltraBarrier | Stainless Steel | Stainless Steel (SS316) | 400-980 | 24 | ISO 9227 tested (5000h) | 15,600 | 19 |

As the data demonstrates, UltraBarrier leads in corrosion resistance and output, making it ideal for large-scale, critical installations. SecureLine offers a balance of performance and rapid deployment capabilities, well-suited for security contractors managing both time and quality constraints.

Customization Solutions: Tailoring Concertina Razor Barbed Tape

Not all security threats are identical, and effective risk mitigation necessitates customized solutions. Whether the requirement involves securing an airport perimeter or protecting a remote energy substation, flexibility is essential. Leading manufacturers now provide comprehensive customization options for concertina razor barbed tape, including adaptable coil sizes (350mm to 1000mm), variable blade shapes (CBT-60, BTO-22, BTO-30), and numerous barb arrangements to match specific deterrence profiles.

In response to customer demand, some suppliers have introduced modular systems featuring stackable coils, anti-tamper fastenings, and hybrid blade alloys for extreme environments. Color-coating and powder-coated finishes allow tape to blend into urban or natural landscapes, increasing both discretion and aesthetic compatibility. Additionally, integration with electronic perimeter monitoring—infrared sensors, break wire alarms, or CCTV mounts—creates a unified physical-technical barrier that outperforms traditional fencing in detection and delay response time by over 45%.

Thorough project assessment, site surveys, and consultation with manufacturers ensure that custom specifications are translated into operational success. This collaborative approach upholds compliance with local safety regulations and environmental standards, critical for facilities situated near residential or protected wildlife areas.

Application Scenarios: Real-World Use Cases

The versatility of barbed tape concertina is evidenced across a wide array of sectors. Correctional institutions utilize double-coil high tensile tape as both inner and outer perimeter fortifications, reducing escape attempts by an average of 85% since 2020. Similarly, electrical substations employ anti-climb concertina to thwart copper theft and vandalism, which, according to a report from the International Energy Security Panel, has dropped by 60% in areas where modern razor tape systems are deployed.

Military compounds and embassies favor modular, rapidly deployable tape systems, allowing security personnel to reinforce access points swiftly in response to threat level changes. Civil airports and logistics centers integrate barbed tape with surveillance networks to provide multi-layered protection against unauthorized access, sabotage, and accidental trespass.

Temporary venues, such as construction sites, disaster relief zones, and outdoor events, also benefit from quick-installation tape, which increases project security without requiring permanent installations. The ability to tailor strength, coil diameter, and blade profile ensures that both permanent and short-term applications achieve their precise deterrence objectives.

Market Trends, Data Insights, and Industry Challenges

The global market for barbed wire tape is projected to reach $695 million by 2027, expanding at a CAGR of 5.8% (2022-2027), as identified in the Security Materials Outlook 2023 publication. Growth drivers include heightened urbanization, escalating geopolitical tensions, and stricter infrastructure protection mandates. Demand is also propelled by advancements in anti-corrosion treatments and eco-friendly production processes.

Despite robust demand, the industry faces persistent challenges: fluctuating raw material costs, international trade regulations affecting steel imports, and an evolving threat landscape that necessitates continuous innovation. Environmental impacts of production—especially when involving zinc or chromium treatments—are under increased scrutiny, with leading manufacturers pivoting towards low-VOC coatings and recycled metals.

To maintain competitive advantage, manufacturers are investing in digital product passports, lifecycle tracking, and AI-driven quality control—each increasing product traceability and long-term sustainability.

Conclusion: The Future of Barbed Wire Tape in Perimeter Security

The future trajectory of barbed wire tape points toward increased integration with smart security infrastructure, greater product customization, and an intensification of sustainability efforts. As intrusion techniques evolve, so too must perimeter defense systems, with concertina razor barbed tape at the forefront of these advances. Facilities and security professionals who invest in state-of-the-art materials, transparent supply chains, and meticulous customization will not only maximize operational protection but also future-proof their security frameworks against emerging threats.

(barbed wire tape)