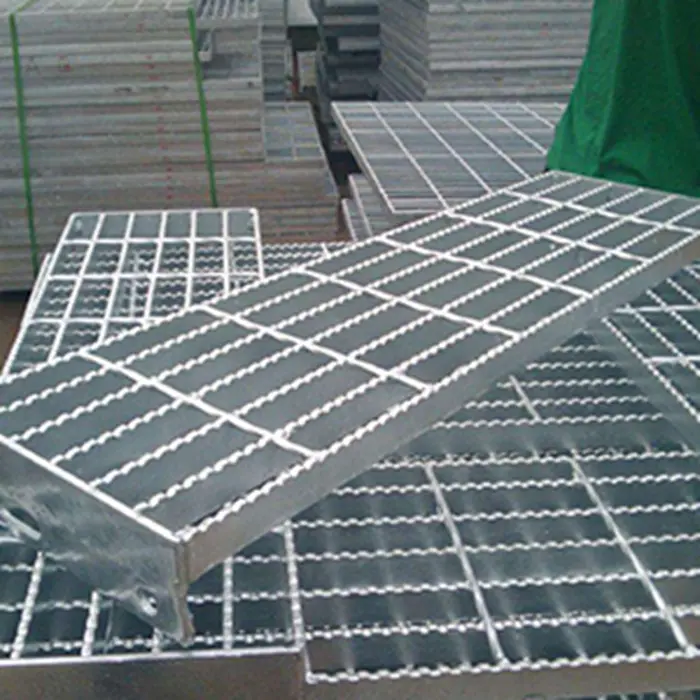

In the vast landscape of modern infrastructure and industrial development, the role of foundational components cannot be overstated. Among these, steel grating stands out as an indispensable material, offering a unique blend of strength, durability, and versatility. From heavy-duty industrial platforms to aesthetically pleasing architectural elements, its applications are as diverse as they are critical. This comprehensive guide delves into the world of steel grating, exploring its technical intricacies, industrial applications, manufacturing prowess, and the strategic considerations for sourcing high-quality solutions, such as our premium Trench cover hot dip galvanized steel grating.

Industry Trends and the Evolving Landscape of Steel Grating

The global market for steel grating is experiencing steady growth, driven by an increasing emphasis on robust infrastructure development, industrial safety standards, and sustainable construction practices. According to recent market analyses, the demand for high-performance steel grating is propelled by expansion in sectors like oil & gas, chemical processing, power generation, wastewater treatment, and mining. Governments worldwide are investing heavily in infrastructure upgrades, including bridges, roadways, and public facilities, all of which require durable and reliable flooring and drainage solutions.

Emerging trends highlight a shift towards enhanced corrosion resistance, lighter yet stronger materials, and more sophisticated customization options. The growing awareness of environmental impact also contributes to the demand for products with longer lifespans and lower maintenance requirements, making solutions like galvanised steel grating particularly attractive. Furthermore, automation in manufacturing and advanced design software are enabling producers to offer more precise and cost-effective steel grating solutions. The market is also seeing increased integration of smart technologies for better inventory management and supply chain efficiency, impacting how companies buy steel grating.

Technical Parameters and Structural Integrity of Steel Grating

Steel grating is typically manufactured from low carbon steel, offering an excellent strength-to-weight ratio. Its design comprises a series of bearing bars, running in one direction, joined by perpendicular cross bars. The spacing and dimensions of these bars determine the grating's load-bearing capacity, deflection characteristics, and overall performance. Key technical parameters include:

- Bearing Bar Size (Depth x Thickness): Crucial for load-carrying capacity. Deeper and thicker bars can support heavier loads over longer spans. Common dimensions range from 20x3mm to 100x10mm.

- Bearing Bar Pitch (Spacing): The center-to-center distance between bearing bars. Standard pitches include 30mm, 40mm, 60mm, and 80mm. Smaller pitches provide greater support and prevent smaller objects from falling through.

- Cross Bar Pitch (Spacing): The center-to-center distance between cross bars. Typically 50mm or 100mm. Affects the lateral stability and appearance of the grating.

- Surface Type:

- Plain (Smooth): Most common, easy to clean.

- Serrated (Anti-slip): Notched bearing bars provide superior slip resistance, essential in wet or oily environments.

- Material Grade: Usually Q235 (equivalent to ASTM A36) or Q345 (equivalent to ASTM A572 Grade 50) structural steel. These grades provide excellent weldability and strength.

- Finish:

- Black (Mill Finish): Uncoated, typically for interior use or when other coatings are applied on-site.

- Hot-Dip Galvanized: The most common and recommended finish for outdoor or corrosive environments, offering superior corrosion protection.

- Painted/Powder Coated: For aesthetic purposes or specific chemical resistance, often applied over galvanization.

Typical Steel Grating Specifications Table

Understanding these parameters is vital when you buy steel grating to ensure it meets the specific requirements of your project.

| Parameter | Description | Common Range/Value | Impact on Performance |

|---|---|---|---|

| Bearing Bar Depth (D) | Vertical height of the bearing bar. | 20mm - 100mm | Directly proportional to load capacity and span. |

| Bearing Bar Thickness (T) | Horizontal thickness of the bearing bar. | 3mm - 10mm | Influences load capacity, stability, and rigidity. |

| Bearing Bar Pitch (Pbb) | Center-to-center spacing of bearing bars. | 30mm, 40mm, 60mm | Determines open area, small object retention, and load distribution. |

| Cross Bar Pitch (Pcb) | Center-to-center spacing of cross bars. | 50mm, 100mm | Affects lateral stability and overall panel stiffness. |

| Material Yield Strength | Minimum stress required to cause plastic deformation. | 235 MPa (Q235), 345 MPa (Q345) | Critical for safe load-bearing capacity and deflection limits. |

| Zinc Coating Thickness | Thickness of the hot-dip galvanized layer. | ≥65 µm (for general applications) | Directly impacts corrosion resistance and lifespan (adhering to ISO 1461/ASTM A123). |

| Open Area Percentage | Percentage of void space in the grating. | 50-80% (depending on mesh size) | Influences ventilation, light penetration, and drainage capabilities. |

Diverse Application Scenarios of Steel Grating

The robust design and inherent versatility of steel grating make it an ideal solution for a multitude of industrial, commercial, and public infrastructure applications. Its ability to provide robust support while allowing for light, air, and fluid passage is invaluable.

- Industrial Platforms and Walkways: In power plants, chemical facilities, refineries, and manufacturing plants, steel grating forms elevated walkways, work platforms, and mezzanines. Its open design allows for excellent ventilation, dissipates heat, and prevents the accumulation of hazardous gases, contributing to a safer working environment.

-

Trench Covers and Drainage Systems: Our product, Trench cover hot dip galvanized steel grating, is specifically designed for this application. It is widely used in roadways, industrial compounds, municipal projects, and port areas to cover drainage trenches, cable ducts, and utility channels. The robust construction can withstand heavy vehicular traffic, while the open mesh ensures efficient drainage of rainwater and spills, preventing flooding and maintaining safe passage. The hot-dip galvanization ensures superior resistance to corrosion from water, chemicals, and road salts.

- Stair Treads: Used in industrial buildings, fire escapes, and public access points, steel grating stair treads provide durable, slip-resistant steps. Serrated options are particularly effective in high-traffic or outdoor areas prone to moisture.

- Architectural Applications: Increasingly, steel grating is employed in modern architecture for facades, sunscreens, and decorative elements due to its clean lines, industrial aesthetic, and ability to control light and airflow.

- Marine and Offshore Environments: Due to its exceptional strength and the protective qualities of galvanised steel grating, it is extensively used on ships, oil rigs, and offshore platforms. It resists the harsh corrosive effects of saltwater and provides slip-resistant walking surfaces, even in adverse weather conditions.

- Wastewater Treatment Plants: In these environments, constant exposure to moisture and corrosive chemicals necessitates materials with high resistance. Steel grating with hot-dip galvanization is ideal for walkways, access platforms, and grit chambers, ensuring longevity and minimal maintenance.

Technical Advantages and Performance Superiority

The inherent design and material properties of steel grating offer several significant technical advantages that contribute to its widespread adoption and superior performance across various sectors.

- High Strength-to-Weight Ratio: Despite being lightweight, steel grating possesses remarkable load-bearing capabilities. This efficiency in material usage translates to easier installation, reduced structural support requirements, and lower overall project costs. It can safely support significant loads while maintaining structural integrity over large spans, minimizing the need for additional supports.

- Excellent Ventilation and Light Penetration: The open mesh design allows for the free passage of air, dissipating heat and preventing the buildup of potentially hazardous gases in industrial environments. This contributes to better air quality and safer working conditions. Furthermore, it permits natural light to filter through, reducing the need for artificial lighting and contributing to energy savings (an advantage often overlooked but critical in large facilities). This aspect is particularly beneficial in multi-story industrial buildings or underground spaces.

- Superior Drainage Capabilities: The large open area ensures rapid and efficient drainage of liquids, preventing standing water and minimizing slip hazards. This is critical in applications like trench covers, process areas, and outdoor walkways where spills or rain are common.

- Exceptional Slip Resistance: Especially when specified with a serrated surface, steel grating provides excellent traction, even in wet, oily, or icy conditions. This significantly enhances safety in industrial settings, reducing the risk of accidents and ensuring compliance with occupational safety standards.

- Low Maintenance and Long Lifespan: When properly manufactured and finished, particularly with hot-dip galvanization, steel grating requires minimal maintenance over its long operational life. The zinc coating provides robust protection against rust and corrosion, even in harsh environments, reducing the need for frequent repairs or replacements. This directly translates to lower lifecycle costs and higher operational uptime for facilities. According to the American Galvanizers Association, a hot-dip galvanized coating can last 50 years or more in many environments without maintenance.

-

Corrosion Resistance (Hot-Dip Galvanized Steel Grating): Our Trench cover hot dip galvanized steel grating excels in this regard. The hot-dip galvanization process provides a metallurgical bond between the steel and a zinc coating, creating a barrier and cathodic protection layer. This dual protection mechanism offers superior resistance against rust and corrosion from water, chemicals, and atmospheric conditions, significantly extending the product's service life compared to untreated or painted steel. This feature is paramount for applications in chemical plants, coastal areas, and wastewater treatment facilities, where exposure to corrosive elements is constant.

Detailed Manufacturing Process of Steel Grating

The production of high-quality steel grating involves a series of precise and controlled steps, ensuring the final product meets stringent performance and durability standards. Our manufacturing process for Trench cover hot dip galvanized steel grating emphasizes precision and quality control at every stage.

Manufacturing Flow of Steel Grating (Forge-Welded Method)

The most common and effective method for manufacturing steel grating is the forge-welding process, which produces a robust and durable product. Unlike casting or CNC machining (which are typically for more intricate, smaller components or specialized parts, not standard grating), forge-welding creates a strong, integral bond.

-

Raw Material Selection:

- Description: High-quality low carbon steel (e.g., Q235B or Q345B, conforming to ASTM A36 or A572 Grade 50 standards) in the form of flat bars (for bearing bars) and twisted square bars or round bars (for cross bars) is carefully selected. Material purity and mechanical properties are checked.

- Key Node: Incoming material inspection (visual, dimensional, material certification).

-

Slitting and Cutting:

- Description: The selected steel plates are precisely slit into individual bearing bars of the required depth and thickness using specialized machinery. Cross bars are cut to specified lengths. CNC cutting ensures dimensional accuracy.

- Key Node: Precision cutting to specified dimensions.

-

Notching (for some types):

- Description: If a certain type of steel grating requires notches in the bearing bars for specific cross bar insertion, this step is performed. For forge-welded grating, this step is often integrated with the welding process where hot cross bars are pressed into bearing bars.

- Key Node: Accurate notching to ensure proper interlocking and welding.

-

Forge Welding (Resistance Welding):

- Description: This is the core of the manufacturing process. Bearing bars are arranged vertically at specified pitches. Pre-heated twisted square bars (cross bars) are then fusion-welded to the bearing bars under immense pressure and high current using an automated welding machine. This process creates a very strong, integral bond without the need for additional filler material, ensuring maximum strength and stability of the steel grating panel.

- Key Node: Automated welding, temperature, pressure, and current control for consistent weld quality.

-

Trimming and Edge Banding:

- Description: After welding, the large grating panels are trimmed to the exact dimensions specified by the client. For enhanced structural integrity and aesthetics, a flat bar (edge band) is often welded around the perimeter of the steel grating panel. This prevents distortion and provides a clean, finished edge.

- Key Node: Precise trimming and secure edge welding.

-

Inspection and Quality Control:

- Description: Each manufactured steel grating panel undergoes rigorous quality checks. This includes visual inspection for defects, dimensional checks (overall size, bar pitch, etc.), straightness, flatness, and weld integrity. Load testing can also be performed to verify compliance with design specifications. Our products adhere to international standards such as ANSI/NAAMM MBG 531 (Metal Bar Grating Manual) and AS 1657 (Fixed platforms, walkways, stairways and ladders – Design, construction and installation).

- Key Node: Comprehensive quality assurance, adherence to ISO 9001:2015 standards.

-

Hot-Dip Galvanizing:

- Description: This is a critical step for our Trench cover hot dip galvanized steel grating. After cleaning the steel grating (degreasing, pickling, rinsing, fluxing), it is immersed in a bath of molten zinc at approximately 450°C (840°F). The zinc metallurgically bonds with the steel, forming a series of highly protective zinc-iron alloy layers and an outer layer of pure zinc. This process provides superior corrosion protection compared to other coating methods. The galvanization process strictly follows standards like ISO 1461 (Hot dip galvanized coatings on fabricated iron and steel articles) and ASTM A123 (Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products).

- Key Node: Proper surface preparation, controlled immersion time, withdrawal speed, and zinc bath composition to ensure uniform coating thickness and adhesion. Coating thickness is measured using magnetic gauges, ensuring it meets or exceeds the minimum requirements (e.g., ≥65 µm for general applications).

-

Final Inspection and Packaging:

- Description: After galvanizing, a final inspection checks for coating quality, adhesion, uniformity, and any post-galvanizing defects. The finished steel grating panels are then carefully bundled and packaged, often with steel bands and wooden pallets, to prevent damage during transit.

- Key Node: Post-galvanizing quality check and secure packaging for shipment.

This meticulous process ensures that our steel grating products, especially the Trench cover hot dip galvanized steel grating, deliver exceptional performance, longevity, and safety in demanding environments. The estimated service life for our hot-dip galvanized products, in typical atmospheric conditions, often exceeds 50 years without maintenance, significantly reducing total lifecycle costs.

Manufacturer Comparison: Choosing the Right Partner to Buy Steel Grating

When looking to buy steel grating, selecting the right manufacturer is as crucial as understanding the product itself. A reliable supplier ensures not only high-quality products but also consistent service, technical support, and timely delivery. Here’s a comparison framework to guide your decision:

Key Factors for Manufacturer Evaluation

| Factor | High-Quality Manufacturer (Our Approach) | Lower-Tier Manufacturer (Risks) |

|---|---|---|

| Quality Certifications | ISO 9001:2015 certified, compliance with ASTM, ANSI, BS EN, AS/NZS standards for steel grating and galvanization (e.g., ASTM A123, ISO 1461). Offers material test certificates. | Lack of formal certifications or relies on outdated ones. May not provide comprehensive material or coating test reports. |

| Manufacturing Process | Automated forge-welding, precise cutting, consistent galvanization thickness, robust quality control at every stage. Transparency in process. | Manual welding, inconsistent dimensions, thinner or uneven galvanization, less stringent quality checks, potentially using inferior raw materials. |

| Customization Capability | Offers extensive customization for sizes, shapes, cut-outs, special finishes, and design support from experienced engineers. | Limited customization options, relies on standard sizes, less likely to provide design assistance or complex solutions. |

| Customer Support & Service | Responsive pre-sales consultation, dedicated project managers, after-sales support, clear warranty and return policies. Decades of industry experience. | Slow response times, lack of technical expertise in support, unclear policies, potential abandonment post-sale. |

| Lead Time & Delivery | Reliable and transparent delivery schedules, efficient logistics, ability to handle large orders and meet tight deadlines. | Frequent delays, inconsistent delivery, difficulty managing large or complex orders. |

| Pricing Model | Competitive pricing reflecting value, quality, and service. Clear cost breakdowns. Focus on long-term value. | Unusually low prices often indicate compromise on material quality, manufacturing standards, or coating thickness. Hidden costs. |

| Reputation & Experience | Strong industry reputation, positive client testimonials, extensive portfolio of successful projects, established service history (e.g., 20+ years). Partnerships with reputable engineering firms. | New or unknown in the market, negative reviews, limited project examples, short operational history. |

Our company, with over two decades of experience in manufacturing and supplying steel grating, particularly our Trench cover hot dip galvanized steel grating, stands firmly on the side of high-quality manufacturing and customer-centric service. We pride ourselves on our ISO 9001 certification and adherence to global standards, ensuring every product we deliver meets the highest benchmarks for safety, durability, and performance. Our long-standing relationships with major industrial clients and infrastructure projects globally serve as a testament to our reliability and authority in the steel grating market.

Customization Solutions for Unique Project Requirements

No two projects are exactly alike, and the ability to provide tailored steel grating solutions is a hallmark of a capable manufacturer. We offer extensive customization options to ensure that the steel grating perfectly integrates with specific project designs and functional demands.

- Size and Shape: Beyond standard panels, we can fabricate steel grating in custom lengths, widths, and complex shapes, including circular, triangular, or irregular patterns to fit unique architectural or structural requirements.

- Cut-outs and Notches: Precise cut-outs for pipes, columns, equipment foundations, or specific access points can be integrated into the grating design, minimizing on-site modifications and ensuring a perfect fit. This is particularly crucial for trench covers around existing utilities.

- Load-Bearing Capacity: We can adjust bearing bar dimensions and spacing to achieve specific load ratings, accommodating anything from pedestrian traffic to heavy vehicular loads (e.g., H-20 or HS-20 load ratings for vehicular trench covers, conforming to AASHTO M306).

- Surface Finish: While hot-dip galvanization is our recommended standard for its superior corrosion resistance, we also offer black (mill finish) or painted/powder-coated options for specific aesthetic or environmental needs.

- Special Features: This includes integrating toe plates (kick plates) for safety, special banding for enhanced strength, hinged sections for easy access to trenches, or provisions for grating fasteners.

- Material Grades: While Q235B is standard, we can work with other steel grades like Q345B for applications requiring higher strength or specific material properties.

Our engineering team works closely with clients from the design phase through to production, utilizing advanced CAD software to develop precise fabrication drawings and ensure that every customized steel grating panel meets exact specifications.

Application Cases and Client Success Stories

Our Trench cover hot dip galvanized steel grating has been successfully deployed in numerous demanding environments globally, demonstrating its robust performance and durability.

-

Case Study 1: Major Refinery Expansion Project (Middle East)

Challenge: A large-scale refinery required thousands of square meters of durable, corrosion-resistant flooring and trench covers for new processing units. The environment was highly corrosive due to exposure to chemicals, oil, and extreme temperatures. Solution: We supplied over 15,000 square meters of custom-fabricated, heavy-duty Trench cover hot dip galvanized steel grating and walkways. The specific design included serrated bearing bars for enhanced slip resistance in potentially oily areas and varied bar pitches to accommodate different load requirements across platforms and trench lines. Outcome: The hot-dip galvanization proved highly effective in resisting the harsh chemical environment, ensuring a projected lifespan exceeding 40 years. The superior drainage capabilities prevented standing liquids, contributing to a safer operational area. The client reported significant improvements in safety records and reduced maintenance overhead due to the grating's robust performance. This project exemplifies our ability to deliver large volumes of specialized steel grating meeting stringent industry standards.

-

Case Study 2: Municipal Stormwater Drainage Upgrade (Southeast Asia)

Challenge: A rapidly developing urban area needed to upgrade its stormwater drainage system along major roadways to cope with increasing rainfall and prevent urban flooding. The trench covers had to withstand heavy vehicular traffic (trucks, buses) and provide efficient water flow. Solution: We provided several kilometers of custom-sized Trench cover hot dip galvanized steel grating designed for H-20 vehicular loading, compliant with AASHTO M306 specifications. The grating featured robust bearing bars (e.g., 40x5mm) and a standard 30mm bearing bar pitch for optimal strength and debris filtration. Outcome: The galvanised steel grating successfully managed torrential downpours, preventing water accumulation on roads and ensuring uninterrupted traffic flow. The durable zinc coating provided excellent resistance to continuous water exposure and road salts, significantly extending the lifespan of the drainage system compared to previous solutions. Local authorities praised the effectiveness and minimal maintenance requirements of the installed grating.

-

Case Study 3: Wastewater Treatment Plant (Europe)

Challenge: A municipal wastewater treatment facility required replacement of its deteriorating platforms and trench covers in areas constantly exposed to corrosive wastewater and chemical fumes. Traditional materials had a short lifespan. Solution: We engineered and supplied customized Trench cover hot dip galvanized steel grating with specific anti-corrosion treatments. All panels were manufactured to exact dimensions to replace existing sections without major structural modifications. The galvanization process was meticulously controlled to ensure maximum coating thickness and uniformity, vital for this aggressive environment. Outcome: Two years post-installation, the galvanised steel grating shows no signs of corrosion, performing exceptionally well in the highly corrosive environment. The facility maintenance team reported a dramatic reduction in repair and replacement costs, highlighting the long-term value and durability provided by our specialized corrosion-resistant steel grating. This project perfectly showcases the energy-saving aspect of longevity and reduced resource consumption for maintenance.

Frequently Asked Questions (FAQ) about Steel Grating

We address common queries regarding steel grating to provide clarity and build trust.

- Q1: What is the primary difference between plain and serrated steel grating?

- A1: The primary difference lies in the surface. Plain steel grating has smooth bearing bars, while serrated steel grating has notched or toothed bearing bars. Serrated grating offers superior slip resistance, especially in wet, oily, or icy conditions, making it ideal for safety-critical areas. Plain grating is generally easier to clean and is suitable for areas where slip hazards are minimal.

- Q2: Why is hot-dip galvanization recommended for steel grating?

- A2: Hot-dip galvanization provides exceptional corrosion resistance. The process creates a metallurgical bond between steel and zinc, forming multiple layers that protect against rust and abrasion. This extends the lifespan of the steel grating significantly, especially in harsh outdoor, industrial, or marine environments, minimizing maintenance and replacement costs. It conforms to international standards like ISO 1461 and ASTM A123.

- Q3: How do I determine the correct load-bearing capacity for my steel grating project?

- A3: Determining load capacity involves assessing the maximum anticipated load (uniform or concentrated), the span of the grating, and acceptable deflection limits. Engineers use design tables and software based on industry standards (e.g., ANSI/NAAMM MBG 531 for bar grating) to calculate the required bearing bar size (depth and thickness) and pitch. Our technical team can assist with these calculations based on your project specifications.

- Q4: Can steel grating be customized for specific dimensions or shapes?

- A4: Absolutely. We offer extensive customization services. Steel grating can be fabricated to precise lengths, widths, and even complex shapes (e.g., circular, triangular, or irregular cut-outs) to fit around pipes, columns, or machinery. Customizations also include specific bar pitches, surface finishes, and the addition of toe plates or hinged sections.

- Q5: What is the typical lead time for ordering steel grating?

- A5: Lead times vary depending on the order quantity, complexity of customization, and current production schedules. For standard steel grating products, lead times typically range from 2-4 weeks. For large or highly customized orders, it may be longer. We provide clear and transparent delivery schedules at the time of quotation and strive to meet all agreed-upon deadlines. Expedited options may be available for urgent projects.

- Q6: What inspection standards does your steel grating adhere to?

- A6: Our manufacturing process adheres strictly to international quality management systems, including ISO 9001:2015. Our steel grating products comply with major industry standards such as ANSI/NAAMM MBG 531 (for dimensional tolerance and load design), ASTM A123 (for hot-dip galvanization quality), and often local standards like AS 1657 (Australia) or BS EN ISO 14122 (Europe) for specific applications. Each batch undergoes rigorous quality control checks for material, dimensions, welding integrity, and coating thickness.

- Q7: What kind of warranty and customer support do you offer?

- A7: We stand by the quality of our products. Our steel grating comes with a comprehensive warranty against manufacturing defects and premature failure under normal operating conditions, typically covering the integrity of the steel and the galvanization for a specified period (e.g., 5-10 years, depending on application and environmental conditions). Our dedicated customer support team is available to assist with technical queries, order tracking, and any after-sales service needs, ensuring a seamless experience from inquiry to installation and beyond. Our commitment to client satisfaction extends throughout the product's lifecycle.

The selection of steel grating is a critical decision that impacts safety, longevity, and operational efficiency of any industrial or civil project. By prioritizing quality, adherence to international standards, and partnering with experienced manufacturers like us, you ensure a durable, reliable, and cost-effective solution. Our Trench cover hot dip galvanized steel grating embodies these principles, offering unparalleled performance for demanding trench and drainage applications.

For further reading and deeper insights into the intricacies of steel grating and galvanization, we recommend consulting authoritative industry publications and academic research.

- "Hot-Dip Galvanizing: A Guide to Process & Performance" - American Galvanizers Association, providing comprehensive information on the benefits and standards of galvanization. https://galvanizeit.org/hot-dip-galvanizing/what-is-hot-dip-galvanizing/the-process

- "Engineering Design and Analysis of Steel Structures" - Relevant chapters often discuss steel grating load tables and deflection limits in structural engineering contexts. (e.g., academic journals like Engineering Structures or Journal of Constructional Steel Research). https://www.sciencedirect.com/journal/journal-of-constructional-steel-research

- "NAAMM Metal Bar Grating Manual (MBG 531)" - A definitive standard for the design and specification of steel grating. https://www.naamm.org/publications/download/MBG%20531-15.pdf