The Indispensable Role of Galvanized Reinforcing Mesh in Modern Construction

In the rapidly evolving landscape of global infrastructure development, the demand for robust, durable, and cost-effective construction materials has never been more critical. At the forefront of this demand is galvanized reinforcing mesh, a foundational component that has revolutionized how structural integrity and longevity are achieved in concrete applications. This specialized form of steel welded wire mesh combines the inherent strength of high-tensile steel with the superior corrosion resistance of a zinc coating, creating a material that significantly extends the service life of concrete structures, even in the most aggressive environments. Unlike conventional plain carbon steel mesh, galvanized variants offer unparalleled protection against rust and degradation, which are common culprits behind structural failures and costly repairs. The strategic integration of this advanced material translates into substantial long-term savings, reduced maintenance cycles, and enhanced safety protocols across a myriad of construction projects. Its unique properties make it an ideal choice for challenging conditions, ranging from marine environments to chemically exposed industrial facilities. As urban centers expand and infrastructure ages, the emphasis on sustainable and resilient building practices becomes paramount. Galvanized mesh directly addresses these imperatives by providing a solution that is not only environmentally conscious due to its extended lifespan but also structurally dependable. Its application is not limited to large-scale public works; it is equally vital in commercial buildings, residential foundations, and specialized architectural designs where aesthetic longevity and structural integrity are paramount. The manufacturing process of this mesh, characterized by precise welding and controlled galvanization, ensures a product that consistently meets stringent international standards, thereby guaranteeing performance and reliability. Industry trends increasingly point towards materials that offer enhanced durability without compromising on flexibility or ease of installation, and galvanized mesh perfectly aligns with this trajectory. This article delves deep into the technological prowess, diverse applications, and profound advantages of this critical construction material, offering a comprehensive guide for industry professionals, procurement specialists, and project managers seeking to optimize their construction methodologies and material selections. We will explore the intricate manufacturing processes, delve into specific technical parameters, analyze real-world application scenarios, and discuss the economic and environmental benefits that position galvanized reinforcing mesh as an indispensable asset in the construction industry's quest for excellence and sustainability.

The Unrivaled Manufacturing Process: Engineering Excellence from Wire to Mesh

The production of high-strength construction mesh concrete steel welded wire reinforcing mesh is a sophisticated industrial process that combines metallurgical precision with advanced manufacturing techniques, culminating in a product of exceptional strength and durability. The journey begins with high-quality steel wire rods, typically low-carbon or high-tensile steel, which are meticulously drawn through a series of dies to achieve the desired wire gauge and tensile strength. This cold drawing process significantly enhances the wire's mechanical properties, including its yield strength and ductility, making it ideal for structural reinforcement. Once the individual wires are prepared, they undergo a precise automated welding process. State-of-the-art resistance welding machines are utilized to join the longitudinal and transverse wires at their intersections, forming a rigid grid pattern. This welding method ensures strong, consistent bonds, preventing wire slippage and maintaining the mesh's structural integrity under stress. The spacing of the wires and the wire diameter are critical parameters, engineered to meet specific load-bearing requirements and industry standards such as ASTM A1064/A1064M or AS/NZS 4671. The accuracy of these dimensions is paramount for effective concrete reinforcement. Following the welding stage, the mesh panels are subjected to the galvanization process, which is the cornerstone of their superior corrosion resistance. While electro-galvanizing offers a thinner, aesthetically uniform zinc coating, hot-dip galvanizing is predominantly preferred for reinforcing mesh due to its significantly thicker and more durable zinc layer. In hot-dip galvanizing, the pre-welded steel welded wire mesh panels are thoroughly cleaned, fluxed to remove oxides, and then immersed in a molten zinc bath at temperatures typically around 450°C (840°F). During immersion, a metallurgical bond forms between the steel and the zinc, creating a series of zinc-iron alloy layers that are harder and more abrasion-resistant than the base steel, topped by a pure zinc outer layer. This multi-layered coating acts as both a barrier protection, shielding the steel from corrosive elements, and cathodic protection, sacrificially corroding to protect the underlying steel if the coating is scratched or damaged. The thickness of this zinc coating, often specified in grams per square meter (g/m²) or micrometers (µm), directly correlates with the mesh's lifespan in harsh environments. Post-galvanization, the mesh panels undergo a rigorous cooling process and are then inspected for coating uniformity, adherence, and defects. Each batch of galvanised reinforcing mesh is subject to stringent quality control checks, including visual inspection, coating thickness measurements using magnetic or eddy current gauges, and adherence tests (e.g., bend tests). Mechanical properties such as tensile strength, yield strength, and elongation are also routinely tested to ensure compliance with international standards like ISO 9001 for quality management systems and specific product standards like ASTM A1064 for steel welded wire mesh for concrete reinforcement. The longevity of galvanized reinforcing mesh is typically measured in decades, far exceeding that of untreated steel in corrosive environments. Its application spans various industries, including civil engineering for bridges and roads, building construction for foundations and slabs, precast concrete manufacturing, industrial flooring in chemical plants (where its anti-corrosion properties are essential), and water treatment facilities. In these typical application scenarios, the corrosion resistance of galvanized mesh significantly reduces maintenance costs and extends the operational life of structures, embodying principles of energy efficiency by preventing the need for frequent material replacement and repairs. This robust manufacturing process, from raw material to final inspection, ensures that each panel of galvanized reinforcing mesh is a testament to engineering excellence, ready to provide unparalleled structural integrity and long-term performance.

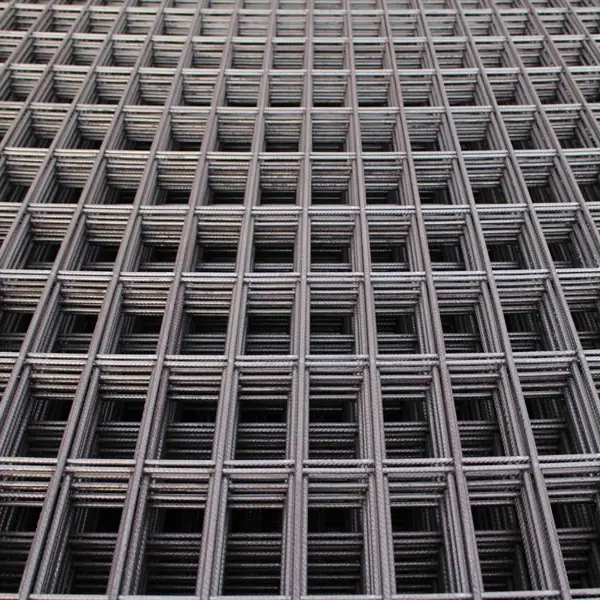

Figure 1: Automated welding lines producing high-strength steel welded wire mesh panels before galvanization.

Technical Specifications and Performance Metrics of Galvanized Reinforcing Mesh

The efficacy and reliability of galvanized reinforcing mesh are quantitatively defined by a precise set of technical specifications and performance metrics that adhere to stringent international and regional standards. Understanding these parameters is crucial for engineers, architects, and procurement professionals to select the appropriate mesh for specific structural requirements and environmental conditions. Key specifications include wire diameter, mesh opening size, panel dimensions, and the quality and thickness of the zinc coating. Wire diameters typically range from 3mm to 12mm, providing varying degrees of tensile strength and load-bearing capacity. The mesh opening, defined by the spacing between longitudinal and transverse wires, can vary significantly, from closely spaced grids of 50mm x 50mm for specialized applications to wider configurations like 200mm x 200mm or 100mm x 300mm for standard concrete slab reinforcement. Panel dimensions are customized to project requirements, commonly available in sizes such as 2.4m x 4.8m or 2.0m x 4.0m, designed to minimize waste and streamline installation. The mechanical properties of the steel wire are paramount, typically conforming to standards such as ASTM A1064/A1064M for steel welded wire mesh for concrete reinforcement, which dictates minimum yield strength (e.g., 485 MPa) and tensile strength (e.g., 550 MPa), along with minimum elongation percentages to ensure ductility. For regions like Australia and New Zealand, AS/NZS 4671 is the governing standard. The galvanization standard, often referencing ASTM A123/A123M for hot-dip galvanizing, specifies the minimum zinc coating weight or thickness, typically ranging from 600 g/m² (equivalent to approximately 85 µm) to over 1000 g/m² for highly corrosive environments. This coating thickness directly impacts the corrosion resistance and anticipated service life of the galvanised reinforcing mesh. For instance, in moderately corrosive atmospheric conditions (e.g., C3 category per ISO 9223), a robust zinc coating can provide protection for 50 years or more, significantly outperforming ungalvanized steel. Furthermore, the weld shear strength, which measures the strength of the welded intersections, is a critical performance indicator, ensuring the mesh retains its structural integrity under concrete stresses. This is typically tested to ensure that individual welds can withstand a certain percentage of the wire's ultimate tensile strength. Manufacturers often provide detailed data sheets that include these specifications, sometimes even with third-party verification for enhanced trust. For instance, an authoritative company might highlight their adherence to ISO 9001 quality management systems, alongside specific product certifications like CE marking for European markets, underscoring their commitment to quality and compliance. Comprehensive testing includes not only tensile and yield strength but also bend tests to assess ductility, and salt spray tests (e.g., ASTM B117) to accelerate corrosion and verify the protective capabilities of the zinc coating. For example, a 1000-hour salt spray test on a sample of galvanized reinforcing mesh can simulate decades of outdoor exposure, providing empirical data on its long-term performance. The consistency of wire spacing and panel flatness are also crucial for ease of installation and uniform stress distribution within the concrete matrix. Below is a general table outlining typical parameters for galvanized reinforcing mesh, though specific requirements will vary by project and application.

| Parameter | Typical Range/Value | Relevant Standard/Notes |

|---|---|---|

| Wire Diameter | 3mm - 12mm | Determines strength; commonly specified in millimeters or gauge. |

| Mesh Opening (Longitudinal x Transverse) | 50x50mm, 100x100mm, 150x150mm, 200x200mm, etc. | Affects reinforcement distribution; custom sizes available. |

| Panel Dimensions | 2.4m x 4.8m, 2.0m x 4.0m, etc. | Tailored for specific project sizes to minimize waste. |

| Steel Grade (Yield Strength) | ≥ 485 MPa (70,000 psi) | ASTM A1064/A1064M; AS/NZS 4671; GB/T 1499.3. |

| Steel Grade (Tensile Strength) | ≥ 550 MPa (80,000 psi) | Minimum value, often higher in practice. |

| Zinc Coating Weight (Hot-Dip Galvanized) | ≥ 600 g/m² (Approx. 85 µm) | ASTM A123/A123M for general hot-dip; ISO 1461. Higher for severe conditions. |

| Zinc Coating Adhesion | No peeling or flaking during bend test | Ensures long-term protective integrity. |

| Weld Shear Strength | Typically 35% of wire's ultimate tensile strength | Ensures robust intersections; specific value per standard. |

| Corrosion Resistance (Salt Spray) | 1000+ hours with minimal red rust | ASTM B117; indicates superior durability in corrosive environments. |

These specifications underscore the advanced engineering behind galvanized reinforcing mesh, making it a preferred choice for projects demanding extended structural life and minimal maintenance, even in the face of aggressive environmental factors. The meticulous control over each parameter ensures that the product delivered meets and often exceeds the performance expectations for critical concrete reinforcement applications.

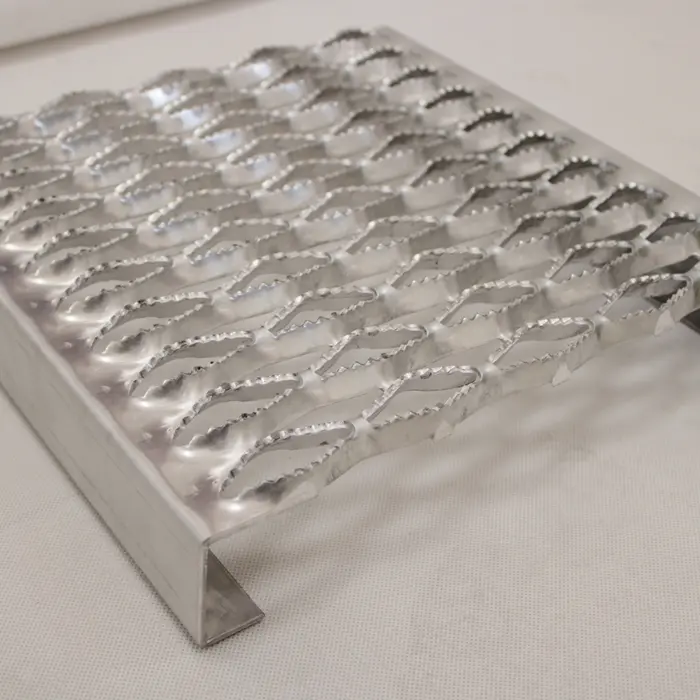

Figure 2: Close-up of high-quality galvanized reinforcing mesh showcasing uniform wire spacing and consistent zinc coating.

Versatile Applications Across Industries: Where Galvanized Reinforcing Mesh Excels

The inherent strength, precise engineering, and superior corrosion resistance of galvanized reinforcing mesh position it as an indispensable material across an expansive array of industries and diverse application scenarios. Its adaptability makes it suitable for projects ranging from large-scale civil engineering marvels to specialized industrial installations, where durability and longevity are paramount. In general civil engineering, galvanized reinforcing mesh is extensively used in the construction of highways, airport runways, and bridge decks. These infrastructures are constantly exposed to varying weather conditions, de-icing salts, and heavy traffic loads, which accelerate corrosion in traditional reinforcement. The zinc coating on the mesh provides a vital barrier against these aggressive elements, significantly prolonging the lifespan of these critical transportation arteries and reducing the frequency of costly repairs and traffic disruptions. For instance, in coastal regions or areas prone to high humidity and salt spray, the application of galvanised reinforcing mesh in bridge piers and structural elements offers unparalleled protection against chloride ingress, a leading cause of concrete deterioration. In the building and construction sector, its applications are equally diverse. It is widely employed in concrete slabs, foundations, walls, and flooring for both commercial and residential buildings. For industrial floors, especially in factories, warehouses, and logistics centers where heavy machinery and constant traffic induce significant stress, steel welded wire mesh provides uniform reinforcement, preventing cracking and spalling. When galvanized, these floors are further protected against chemical spills, water exposure, and abrasive wear, ensuring a stable and long-lasting surface. Consider a food processing plant or a chemical storage facility: the concrete floors are routinely exposed to corrosive agents. Here, galvanized reinforcing mesh offers essential resistance, safeguarding the structural integrity of the flooring system. Moreover, in the realm of precast concrete, galvanized reinforcing mesh is a preferred choice for manufacturing precast panels, pipes, and beams. The use of pre-cut, factory-produced mesh ensures precise reinforcement placement and speeds up the production process, contributing to off-site construction efficiencies. Its corrosion resistance means these precast elements retain their structural integrity for longer, whether they are used in underground drainage systems, building facades, or modular construction components. An illustrative example of its utility lies in stormwater drainage systems, where concrete pipes and culverts are continuously submerged or exposed to moisture and potentially corrosive run-off. The galvanized mesh ensures the longevity of these crucial components, preventing premature collapse due to internal corrosion. Beyond these primary uses, galvanized reinforcing mesh also finds application in specialized fields. In agriculture, it's used for concrete animal stalls, feed pads, and silage pits, where animal waste and moisture can be highly corrosive. In marine structures like docks, jetties, and seawalls, where constant exposure to saltwater demands extreme corrosion resistance, galvanized reinforcing mesh provides a durable solution that resists the aggressive chloride ions. Furthermore, it is utilized in retaining walls and slope stabilization projects, offering both structural support and erosion control. Its ease of handling and precise dimensions, compared to traditional rebar, reduce installation time and labor costs on site, while its extended lifespan translates to significant whole-life cost savings for project owners. This broad spectrum of applications underscores the material's versatility and its critical role in enhancing the durability, safety, and economic viability of modern construction and infrastructure projects, truly making it a high-strength construction mesh for diverse concrete steel applications.

Figure 3: Galvanized reinforcing mesh installed in a concrete slab foundation, ready for pouring.

Key Advantages and Benefits of Galvanized Reinforcing Mesh

The strategic adoption of galvanized reinforcing mesh in construction projects offers a multitude of technical and economic advantages that significantly outweigh those of conventional, untreated steel reinforcement. These benefits translate directly into enhanced structural performance, extended asset lifespan, and considerable cost savings over the entire project lifecycle, making it a preferred choice for discerning B2B decision-makers. Firstly, its unparalleled corrosion resistance is the most significant advantage. The hot-dip galvanization process applies a robust zinc coating that acts as a sacrificial anode, protecting the underlying steel even if the coating is scratched. This property is crucial in environments prone to moisture, chlorides (from de-icing salts or marine air), or aggressive chemicals. Unlike ungalvanized rebar, which can rust and expand, leading to concrete spalling and structural failure (a phenomenon known as "concrete cancer"), galvanized reinforcing mesh maintains its integrity, preventing premature deterioration and expensive remedial work. This extends the service life of concrete structures by decades, often doubling or tripling it in harsh conditions. Secondly, improved bond strength with concrete is another critical factor. While some initial studies suggested potential issues, modern research and advanced galvanization techniques ensure an excellent bond between the zinc-coated steel and concrete. The slightly rougher surface created by hot-dip galvanizing can even enhance mechanical interlocking, ensuring efficient stress transfer within the composite material. This leads to more effective load distribution and crack control, minimizing the width of micro-cracks that might form, thereby further preventing corrosive agents from reaching the steel. Thirdly, its ease of installation and reduced labor costs are notable operational benefits. Steel welded wire mesh comes in pre-fabricated panels, eliminating the need for on-site cutting and tying of individual rebar pieces, a time-consuming and labor-intensive process. The precise spacing of wires ensures uniform reinforcement throughout the concrete pour, simplifying quality control. This pre-fabrication significantly accelerates project timelines, allowing for faster completion and earlier occupancy or operational readiness. For example, large slab areas can be covered much quicker with mesh panels than with individually tied bars, leading to substantial savings in labor hours and overall project duration. Fourthly, the long-term cost-efficiency of galvanized reinforcing mesh is a compelling economic argument. While the initial material cost of galvanized mesh might be marginally higher than that of plain steel mesh, the total cost of ownership is significantly lower. This is primarily due to reduced maintenance requirements and the extended lifespan of the structure. Avoiding costly repairs, rehabilitation, or premature replacement translates into massive savings over the decades-long operational life of a building or infrastructure asset. A typical lifecycle cost analysis often reveals a compelling return on investment for using galvanised reinforcing mesh, particularly in infrastructure projects where maintenance access is difficult or disruptive. Fifthly, the sustainability aspect aligns with modern green building practices. By extending the lifespan of structures, galvanized reinforcing mesh reduces the need for frequent material replacement, thereby lowering the carbon footprint associated with manufacturing, transportation, and construction waste. Zinc, being a natural and recyclable material, further enhances its environmental profile. Finally, the consistently high quality and adherence to strict standards, such as ISO and ASTM, ensure predictable performance. Reputable manufacturers provide comprehensive test data, quality assurance protocols, and often offer extended warranties, instilling confidence in the product's reliability and integrity. These multifaceted advantages position galvanized reinforcing mesh as an intelligent, forward-thinking investment for any concrete construction project, ensuring not only structural excellence but also long-term economic and environmental benefits.

Figure 4: A construction worker inspecting installed galvanized reinforcing mesh panels, highlighting ease of handling and placement.

Choosing the Right Partner: Manufacturer Comparison and Custom Solutions

Selecting the optimal manufacturer for galvanized reinforcing mesh is as critical as the material itself. The market offers various suppliers, but discerning clients, particularly those in the B2B sector, must evaluate potential partners based on a comprehensive set of criteria that extend beyond mere price points. A truly authoritative and trustworthy manufacturer distinguishes itself through consistent product quality, robust technical support, customization capabilities, and proven industry experience. Key factors to consider include the manufacturer's adherence to international quality standards, such as ISO 9001, which signifies a commitment to rigorous quality management processes from raw material sourcing to final product inspection. Look for certifications that validate product conformity to specific standards like ASTM A1064/A1064M for steel welded wire mesh and ASTM A123/A123M for hot-dip galvanization. Transparency in providing test reports (e.g., tensile strength, weld shear strength, zinc coating thickness) from independent third-party laboratories is a strong indicator of reliability and trustworthiness. Furthermore, a manufacturer's service history and industry reputation speak volumes. Longevity in the business, coupled with a portfolio of successful projects and positive client testimonials, demonstrates consistent performance and reliability. Companies with extensive service years (e.g., over two decades) often possess a deeper understanding of industry challenges and can offer more refined solutions. Technical expertise is another cornerstone. A leading manufacturer should have a dedicated engineering team capable of providing expert advice on mesh specifications, application suitability, and structural design considerations. This includes guiding clients on optimal wire diameters, mesh sizes, and panel configurations for maximum efficiency and structural integrity. For example, they should be able to advise on specific zinc coating weights required for marine environments versus standard construction, ensuring that the galvanised reinforcing mesh is perfectly suited to its intended application. Customization capabilities are paramount in large-scale or specialized projects. While standard mesh panels are widely available, many projects require bespoke solutions. A top-tier manufacturer should offer extensive customization options, including:

- Non-Standard Mesh Sizes: Producing panels with unique dimensions to minimize cutting waste on-site.

- Varied Wire Gauges: Combining different wire diameters within the same mesh panel for targeted reinforcement.

- Irregular Mesh Openings: Designing variable spacing for specific load distribution requirements.

- Pre-Bent or Shaped Panels: Fabricating mesh to fit curved or irregular concrete forms, enhancing ease of installation.

- Specific Zinc Coating Thicknesses: Tailoring the galvanization level to extreme environmental conditions.

Moreover, lead times and logistical capabilities are crucial for project scheduling. A reliable supplier should have efficient production capacities and a robust supply chain to ensure timely delivery, especially for large volume orders or projects with tight deadlines. Post-sales support, including clear warranty policies, technical assistance during installation, and responsiveness to any issues, completes the picture of a dependable partner. For example, a manufacturer offering a 10-year warranty on their galvanization quality demonstrates significant trust in their product's durability. In contrast, smaller or less experienced manufacturers might offer lower prices but could compromise on consistency, galvanization quality, or delivery reliability, leading to long-term issues and unforeseen costs. Partnering with a proven expert in galvanized reinforcing mesh ensures access to premium products and comprehensive support, contributing significantly to project success and structural longevity. When evaluating manufacturers, it is advisable to request samples, factory tours (if feasible), and detailed case studies demonstrating their track record in similar projects. This due diligence ensures that the chosen supplier is not just a vendor but a strategic partner invested in the long-term success of your construction endeavors.

Real-World Impact: Application Case Studies and Success Stories

The practical advantages of galvanized reinforcing mesh are best illustrated through real-world application case studies, demonstrating its effectiveness in diverse and challenging environments. These examples highlight how its superior corrosion resistance, structural integrity, and ease of installation have contributed to the success and longevity of various critical infrastructure and building projects globally. One notable case involved a major coastal highway bridge rehabilitation project in a region susceptible to high salt exposure and constant humidity. The existing bridge, constructed with conventional steel rebar, showed significant signs of concrete spalling and rust degradation after only two decades of service. Engineers specified galvanized reinforcing mesh for the new deck slabs and repair sections of the piers. The choice was driven by the need to prevent future chloride-induced corrosion, which is rampant in marine environments. The use of pre-fabricated galvanised reinforcing mesh panels significantly streamlined the installation process, reducing the overall construction time by approximately 15% compared to what would have been required for tying traditional rebar on site. Five years post-completion, inspections revealed no signs of concrete deterioration or rebar corrosion, a stark contrast to the previous structure, validating the long-term protective benefits of galvanization and the durability of the high-strength construction mesh concrete steel welded wire reinforcing mesh. Another compelling example is its application in a large-scale industrial facility's chemical storage area. The concrete flooring in this facility was constantly exposed to dilute acids, alkalis, and various industrial solvents, leading to rapid degradation of untreated concrete and reinforcement. The solution involved casting new heavy-duty concrete slabs reinforced with custom-fabricated galvanized reinforcing mesh featuring an extra-thick zinc coating (specified at over 1000 g/m²). This provided a superior chemical barrier and cathodic protection for the steel. After three years of rigorous operation, the floor exhibits exceptional resistance to chemical attack and heavy point loads from machinery, with no signs of rebar corrosion or concrete spalling. This case highlights how tailored galvanization levels can address specific environmental challenges, offering robust, long-term performance where standard materials would fail. Furthermore, in the residential and commercial building sector, a multi-story car park project faced challenges with rapid degradation of its concrete decks due to repeated exposure to de-icing salts carried by vehicles in winter months. The design team opted for galvanized reinforcing mesh in the suspended concrete slabs of all parking levels. The ease of laying large mesh sheets greatly accelerated the concrete pouring schedule, reducing labor costs and allowing the car park to open sooner. Post-construction monitoring, including chloride penetration tests, demonstrated a significantly lower rate of chloride ingress into the concrete and no corrosion activity on the galvanized mesh, indicating a substantially extended service life for the structure compared to conventional reinforcement. This project serves as a testament to the material's efficacy in preventing costly salt-induced corrosion in common urban infrastructure. Finally, an agricultural client implemented galvanized reinforcing mesh in the construction of new feed pads and animal handling areas where continuous exposure to animal waste, urine, and moisture creates a highly corrosive environment. The robust zinc coating on the mesh prevented the rapid corrosion typical of standard reinforcement in such settings, ensuring the integrity and hygiene of the concrete surfaces for over seven years without significant maintenance. These diverse case studies collectively underscore the tangible benefits and proven performance of galvanized reinforcing mesh across varying industries and environmental conditions. They demonstrate not only its technical superiority in corrosion resistance and structural support but also its practical advantages in terms of installation efficiency and long-term cost savings, cementing its reputation as a reliable and effective solution for demanding concrete reinforcement applications.

Ensuring Excellence: Quality Assurance and Industry Certifications

The commitment to quality assurance and adherence to stringent industry certifications are fundamental pillars that distinguish a reliable supplier of galvanized reinforcing mesh. For B2B stakeholders, these assurances are not mere formalities but critical indicators of product reliability, performance consistency, and ultimately, project success. A reputable manufacturer implements a multi-faceted quality control regimen that spans the entire production lifecycle, from raw material inspection to final product dispatch. This begins with the meticulous selection of high-quality steel wire rods, ensuring they meet specific metallurgical compositions and mechanical properties required for the production of high-strength steel welded wire. Upon receipt, incoming materials undergo rigorous testing for chemical composition, tensile strength, and ductility. During the wire drawing and welding phases, continuous in-process checks are performed to verify wire diameter uniformity, precise mesh spacing, and the integrity of every weld point. Advanced automated systems often incorporate laser measurement and visual inspection to ensure dimensional accuracy and weld consistency, minimizing deviations from specified tolerances. The galvanization process, being a critical stage, is subject to particularly stringent quality control. This includes regular monitoring of the zinc bath temperature and composition, ensuring optimal conditions for uniform coating application and metallurgical bonding. Post-galvanization, each panel of galvanised reinforcing mesh undergoes thorough inspection for coating thickness, adhesion, and visual defects. Coating thickness is typically measured using non-destructive methods such as magnetic or eddy current gauges, with results documented for traceability. Adhesion tests, often involving a simple bend test, verify that the zinc coating remains intact and does not flake or peel, indicating a strong bond between the zinc and steel. Finally, mechanical properties of the finished galvanized reinforcing mesh, such as tensile strength, yield strength, and weld shear strength, are routinely tested on samples from each production batch in an accredited laboratory. These tests ensure the product consistently meets or exceeds the requirements of relevant engineering standards. Industry certifications serve as external validation of a manufacturer's internal quality processes and product conformity. For galvanized reinforcing mesh, key certifications and standards include:

- ISO 9001: A globally recognized standard for quality management systems, demonstrating a manufacturer's commitment to consistent quality, customer satisfaction, and continuous improvement.

- ASTM A1064/A1064M: The standard specification for steel welded wire mesh for concrete reinforcement in North America, covering dimensions, properties, and testing.

- ASTM A123/A123M: The standard specification for zinc (hot-dip galvanized) coatings on iron and steel products, ensuring the quality and durability of the galvanization.

- AS/NZS 4671: The Australian and New Zealand standard for steel reinforcing materials, including steel welded wire mesh.

- EN 10080 & EN 10244: European standards covering steel for the reinforcement of concrete and steel wire for ropes and cables respectively, applicable for European markets.

- CE Marking: For products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

Beyond these, some manufacturers also provide Environmental Product Declarations (EPDs) or demonstrate adherence to sustainable manufacturing practices, aligning with the growing demand for green building materials. Authoritative manufacturers often collaborate with third-party inspection bodies to conduct independent audits and certifications, further enhancing trust and credibility. For instance, a major infrastructure project might require a supplier to have their galvanized reinforcing mesh batch-tested by an accredited independent laboratory before shipment. This commitment to transparency and verifiable quality assurance not only builds confidence but also mitigates risks for project managers and owners, ensuring that the selected high-strength construction mesh concrete steel welded wire reinforcing mesh performs as expected, delivering long-term structural integrity and peace of mind.

Frequently Asked Questions (FAQ) about Galvanized Reinforcing Mesh

- Q1: What is the primary advantage of galvanized reinforcing mesh over standard ungalvanized mesh?

- The primary advantage lies in its superior corrosion resistance. The zinc coating on galvanized reinforcing mesh provides a robust barrier and cathodic protection, preventing rust and degradation of the steel. This significantly extends the lifespan of concrete structures, especially in corrosive environments like those with high moisture, chloride exposure (e.g., de-icing salts, marine air), or industrial chemicals, where standard steel would rapidly corrode, leading to concrete spalling and structural failure. This enhanced durability translates into reduced maintenance costs and greater long-term reliability.

- Q2: What standards should I look for when sourcing galvanised reinforcing mesh?

- When sourcing galvanised reinforcing mesh, it's crucial to ensure compliance with relevant industry standards. Key standards include ASTM A1064/A1064M (for welded wire reinforcement), ASTM A123/A123M (for hot-dip galvanization specifications), and ISO 9001 (for quality management systems). Regional standards like AS/NZS 4671 (Australia/New Zealand) or EN standards (Europe) may also be applicable depending on your project's location. A reputable manufacturer will readily provide documentation and certifications proving adherence to these standards, often accompanied by third-party test reports for the steel welded wire mesh.

- Q3: Can galvanized reinforcing mesh be customized for specific project needs?

- Absolutely. Leading manufacturers of high-strength construction mesh concrete steel welded wire reinforcing mesh offer extensive customization options. This includes varying wire diameters, bespoke mesh opening sizes (e.g., non-standard square or rectangular patterns), custom panel dimensions to minimize waste on site, and even different zinc coating thicknesses to suit the specific environmental corrosivity of a project. Some manufacturers can also produce pre-bent or shaped panels for complex concrete forms, significantly enhancing installation efficiency and reducing labor on demanding construction sites.

- Q4: How does the delivery cycle work for large orders of galvanized reinforcing mesh?

- The delivery cycle for large orders depends on several factors, including the volume, customization requirements, current production schedule, and shipping logistics. Reputable manufacturers typically have established production capacities to handle significant orders efficiently. Upon order confirmation and finalization of specifications, a production timeline will be provided. Standard products usually have shorter lead times (e.g., 2-4 weeks), while highly customized orders may require more time (e.g., 4-8 weeks). Manufacturers work closely with clients to coordinate delivery schedules to align with project timelines, offering various shipping options (e.g., sea freight, rail, truck) to optimize cost and speed for the steel welded wire mesh.

- Q5: What kind of warranty and customer support can I expect for galvanized reinforcing mesh?

- A reliable manufacturer will offer a comprehensive warranty on their galvanized reinforcing mesh, typically covering material defects and the integrity of the zinc coating for a specified period (e.g., 5-10 years, or even longer depending on the application and coating thickness). This warranty provides assurance against premature failure due to manufacturing flaws or inadequate galvanization. In terms of customer support, expect responsive communication channels (email, phone), technical assistance from experienced engineers, and post-sales support for any queries regarding installation, maintenance, or product performance. A strong customer support framework underscores a manufacturer's commitment to client satisfaction and long-term partnership.

Future Outlook and Conclusion

The trajectory of modern construction is undeniably moving towards materials that offer superior durability, sustainability, and efficiency. Galvanized reinforcing mesh stands at the nexus of these evolving demands, representing a critical advancement in concrete reinforcement technology. As global populations continue to urbanize and infrastructure ages, the imperative to build resilient, long-lasting structures becomes more pressing. Climate change and increasing exposure to environmental corrosives further amplify the need for materials that can withstand harsh conditions without rapid deterioration. In this context, the inherent corrosion resistance of galvanised reinforcing mesh is not just an advantage, but a necessity, ensuring that critical assets like bridges, high-rise buildings, and industrial facilities maintain their structural integrity for generations. The ongoing innovation in manufacturing processes, including advancements in automated welding and hot-dip galvanization techniques, continues to enhance the quality and cost-effectiveness of this material. Research into advanced zinc alloy coatings and duplex systems (combining galvanizing with protective paints) promises even greater levels of corrosion protection and extended service life for steel welded wire mesh in extremely aggressive environments. Furthermore, the growing emphasis on lifecycle cost analysis in project planning reinforces the economic viability of choosing galvanized reinforcing mesh. While initial material costs might be higher than plain steel, the significant savings realized through reduced maintenance, repair, and premature replacement efforts over the decades of a structure's lifespan present a compelling return on investment. This long-term economic benefit, coupled with the environmental advantages of reduced material consumption and waste, positions galvanized reinforcing mesh as a sustainable choice for forward-thinking construction. For B2B decision-makers, architects, and engineers, understanding and leveraging the full potential of high-strength construction mesh concrete steel welded wire reinforcing mesh is essential. It's not merely about specifying a product; it's about investing in the longevity, safety, and economic efficiency of their projects. By partnering with reputable manufacturers who uphold stringent quality standards, offer extensive customization, and provide robust technical support, clients can ensure they are deploying a solution that meets the most demanding structural requirements and environmental challenges. As the industry continues to push the boundaries of what's possible in construction, galvanized reinforcing mesh will undoubtedly remain a cornerstone of resilient and sustainable building practices, shaping the infrastructure of tomorrow with unparalleled strength and durability.

References and Further Reading

- American Galvanizers Association - Corrosion Protection: Provides detailed information on the corrosion protection mechanisms of hot-dip galvanizing.

- ASTM International - ASTM A1064/A1064M: Standard Specification for Steel Welded Wire Reinforcement, Plain and Deformed, for Concrete.

- International Organization for Standardization - ISO 9223:2012: Corrosion of metals and alloys — Corrosivity of atmospheres — Classification, determination and estimation by environmental parameters.

- ScienceDirect - Reinforcing Mesh: Academic articles and overviews on the properties and applications of reinforcing mesh in concrete structures.

- American Concrete Institute (ACI) - ACI 318-19: Building Code Requirements for Structural Concrete and Commentary, which references reinforcement standards.