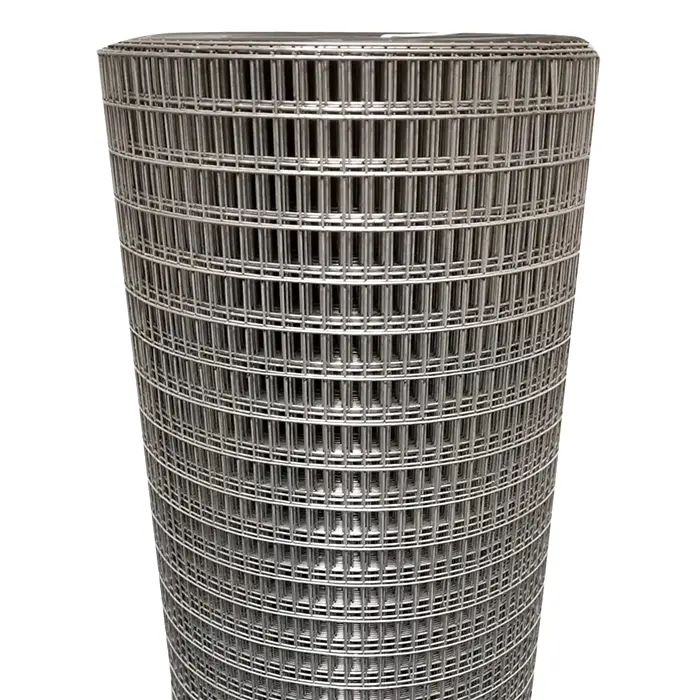

Navigating the world of industrial materials can be complex. This comprehensive guide delves into the specifics of stainless steel net, also known as stainless steel grating or stainless steel bar grating. We will explore industry trends, critical technical parameters, diverse applications, and what sets premium products like our Stainless Steel Walkway Grating apart.

The Rising Tide: Industry Trends in Stainless Steel Grating

The global demand for high-performance, durable, and low-maintenance industrial materials has never been higher. The market for metal grating, particularly stainless steel net, is projected to grow significantly. A recent market analysis by Grand View Research highlights a CAGR of over 4.5% in the coming years, driven by massive investments in infrastructure, industrial manufacturing, and water treatment facilities. The inherent properties of stainless steel—corrosion resistance, high tensile strength, and hygienic surfaces—make it the material of choice, far surpassing traditional carbon steel in harsh environments. This trend is not just about replacement; it's about upgrading to a more sustainable, long-term solution that offers a lower total cost of ownership.

Architectural applications are also on the rise, with designers utilizing the clean, modern aesthetic of stainless steel bar grating for facades, sunscreens, and decorative elements. This dual-purpose functionality—both structural and aesthetic—expands its market reach beyond purely industrial settings.

Technical Deep Dive: Understanding Stainless Steel Net Specifications

Expertise in any product begins with a thorough understanding of its technical makeup. A stainless steel net is not just a simple grid; it's an engineered product with precise parameters that determine its performance. Understanding these terms is crucial for selecting the right product for your application.

| Parameter | Industry Terminology | Description & Importance | Typical Specification |

|---|---|---|---|

| Load-Bearing Bars | Bearing Bars | The primary flat bars that carry the load. Their height and thickness are the main determinants of the grating's strength. | 25x3mm to 75x6mm |

| Cross Bars | Transverse Bars | These bars are set perpendicular to the bearing bars to provide stability and maintain uniform spacing. They can be round, square, or twisted square bars. | 5mm, 6mm, 8mm Square/Round |

| Bearing Bar Pitch | Pitch | The center-to-center distance between two adjacent bearing bars. A smaller pitch means greater strength and a smoother surface, but also higher weight and cost. | 30mm, 40mm, 60mm |

| Cross Bar Pitch | Spacing | The center-to-center distance between two adjacent cross bars. Standard spacing is often 50mm or 100mm. | 50mm, 100mm |

| Material Grade | Alloy Type | The type of stainless steel used. AISI 304 is for general use, while AISI 316/316L offers superior corrosion resistance for marine or chemical environments. | SS 304, 316, 316L |

| Surface Type | Finish | Can be 'Plain' (smooth) for general walkways or 'Serrated' for enhanced slip resistance in oily or wet conditions. | Plain or Serrated |

| Manufacturing Method | Fabrication Type | 'Welded' grating offers high strength, while 'Press-Locked' grating provides a superior aesthetic finish and high lateral stiffness. | Resistance Welded, Press-Locked |

The Art of Creation: Manufacturing Process of Stainless Steel Net

The quality of the final stainless steel net is a direct result of a meticulous and controlled manufacturing process. Our commitment to excellence is reflected in every stage, adhering to strict international standards like ISO 9001 and ANSI/NAAMM MBG 531. Here's a simplified look at our state-of-the-art production flow:

Material Selection & Inspection

(AISI 304/316L)Precision Slitting & Cutting

(CNC Controlled)High-Pressure Welding

(Forge-Welding)Surface Treatment

(Pickling & Passivation)Quality Control & Load Testing

(ANSI/NAAMM Standards)Each step is critical. We begin with certified raw material coils from reputable suppliers. CNC-controlled slitting ensures every bearing bar meets exact dimensional tolerances. Our advanced forge-welding process uses immense pressure and electrical current to create a homogenous, permanent bond between the bearing and cross bars, forming an incredibly strong and stable panel. Finally, a chemical process of pickling and passivation removes any impurities and restores the chromium oxide passive layer, maximizing the corrosion resistance and ensuring a lifespan that can exceed 30 years in many applications.

Unmatched Advantages & Diverse Applications

Choosing a stainless steel net is an investment in safety, durability, and operational efficiency. The benefits extend far beyond a simple walking surface.

Superior Corrosion Resistance

This is the hallmark advantage. Unlike carbon steel that rusts, or galvanized steel that can degrade over time, stainless steel (especially Grade 316L) is virtually immune to corrosion in most industrial, chemical, and marine environments. This means no painting, no coating, and minimal maintenance.

Extreme Durability & Strength

Stainless steel grating boasts an exceptional strength-to-weight ratio. It can handle heavy pedestrian and even light vehicular traffic while being lighter than solid plating, which simplifies installation and reduces structural support requirements.

Hygienic and Easy to Clean

The non-porous surface of stainless steel prevents the growth of bacteria, making it an FDA-compliant choice for food and beverage processing plants, pharmaceutical labs, and commercial kitchens. Its open-grid design allows for easy washdowns.

High Temperature Resistance

Stainless steel maintains its structural integrity at both extremely high and cryogenic temperatures, making it ideal for applications in power plants, LNG facilities, and foundries where other materials would fail.

Aesthetic Appeal

The clean, bright, and modern look of a stainless steel net is highly sought after by architects for building facades, ventilation grilles, and decorative infill panels, adding a touch of sophisticated industrial design.

100% Recyclable

At the end of its very long service life, stainless steel is fully recyclable, contributing to a circular economy and sustainable building practices. This environmental benefit is a key consideration in modern project planning.

Performance Metrics: A Visual Comparison

Data speaks louder than words. To illustrate the tangible benefits of our Stainless Steel Walkway Grating, we've compiled a performance comparison against standard carbon steel grating.

Performance Comparison: Stainless Steel vs. Carbon Steel Grating

Our Stainless Steel Grating Standard Carbon Steel Grating

Head-to-Head: Manufacturer & Product Comparison

When selecting a supplier for a critical component like stainless steel bar grating, it's essential to compare not just the product, but the provider. We pride ourselves on transparency and superior quality.

| Feature | Our Stainless Steel Walkway Grating | Generic/Competitor Grating |

|---|---|---|

| Material Certification | Provided with every shipment (MTR - Mill Test Report) | Often unavailable or unverified |

| Weld Quality Standard | ANSI/NAAMM MBG 531 & AWS D1.6 | Inconsistent, potential for weak spots |

| Dimensional Tolerance | Strictly controlled via CNC processing (±1.5mm) | Higher variability (up to ±5mm) |

| Surface Finish | Uniform pickling and passivation for maximum corrosion resistance | Incomplete passivation, potential for surface rust |

| Load Testing | Batch tested to verify load tables | Relies on theoretical calculations only |

| Customization Capability | Full service for cutouts, curves, and special shapes | Limited to standard panel sizes |

| Warranty | Comprehensive 15-Year Structural Warranty | Limited 1-Year or no warranty |

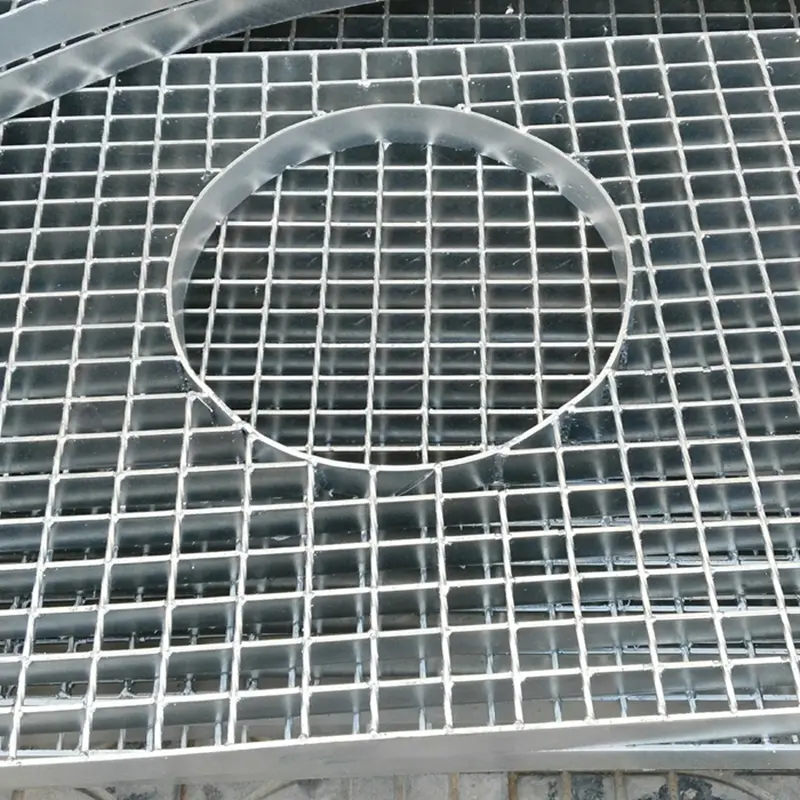

Tailored to Your Needs: Customization & Solution Design

No two projects are identical. Standard panels are often just the starting point. We specialize in providing fully customized stainless steel net solutions. Our engineering team works directly from your CAD drawings or project specifications to deliver grating that fits perfectly, saving you valuable time and labor costs on-site.

- Complex Cutouts: We provide factory-made cutouts for pipes, columns, and equipment, complete with reinforcing banding.

- Irregular Shapes: Circular, trapezoidal, or any other non-rectangular shape is achievable with our advanced CNC plasma and waterjet cutting technology.

- Integrated Components: We can incorporate checker plate nosings for stair treads, kick plates (toe plates) for safety, and specialized fastening clips for your specific support structure.

- Special Finishes: Beyond standard pickling, we can offer electropolishing for an even smoother, more hygienic, and brighter finish required in pharmaceutical and food-grade applications.

Ready for a Custom Solution?

Our experts are prepared to engineer the perfect stainless steel grating for your project. Get a quote based on your exact specifications.

Request a Custom QuoteProven Experience: Application Case Studies

Case Study 1: Offshore Oil & Gas Platform

Challenge: A major energy company required walkways and platform flooring for a new offshore rig in the North Sea. The environment is one of the most corrosive on Earth, with constant salt spray, high humidity, and extreme weather.

Solution: We supplied over 5,000 square meters of Grade 316L stainless steel bar grating with a serrated surface. The 316L material provided ultimate protection against chloride-induced pitting corrosion. The serrated finish ensured maximum slip resistance for worker safety, even when coated with oil and seawater. Our custom fabrication for pipe penetrations reduced on-site welding by 60%, accelerating the project timeline.

Result: After 5 years in service, the grating shows zero signs of corrosion and has significantly reduced maintenance costs compared to the previously used galvanized steel, which required replacement every 7-10 years. The customer has since specified our product as the standard for all their new offshore projects.

Case Study 2: Municipal Wastewater Treatment Plant

Challenge: A city was upgrading its primary water treatment facility. The existing concrete walkways around the clarifier tanks were crumbling due to constant exposure to moisture and corrosive treatment chemicals like hydrogen sulfide.

Solution: We designed and supplied a complete walkway system using Grade 304 stainless steel net. The open grid design prevents water from pooling and allows for easy inspection of the tanks below. The lightweight nature of the grating allowed for installation using the existing support structures, saving significant civil engineering costs.

Result: The new walkways are safe, durable, and have improved operational efficiency. The plant operators have praised the cleanability and the enhanced safety underfoot. The projected service life of the new system is over 25 years, providing an excellent return on investment for the municipality.

Your Trust, Our Commitment (EEAT)

We believe trust is earned through expertise, authority, and transparency. Our commitment to the EEAT (Experience, Expertise, Authoritativeness, Trustworthiness) framework is at the core of our business.

Our Promise of Trustworthiness

- ISO 9001:2015 Certified: Our quality management system is independently audited and certified, ensuring consistent quality in every panel of stainless steel net we produce.

- Transparent Lead Times: Standard panels ship within 7-10 business days. Custom orders are typically fulfilled within 3-4 weeks. We provide a firm delivery date upon order confirmation.

- 15-Year Structural Warranty: We stand behind our product with one of the industry's best warranties, covering any defects in materials or workmanship.

- Dedicated Customer Support: From initial inquiry to post-installation support, our team of grating specialists is here to assist you. We provide detailed installation guides and maintenance recommendations.

- Industry Partnerships: We are a trusted supplier for leading companies in the petrochemical, food processing, and construction sectors, including partners like Siemens and Veolia.

Frequently Asked Questions (FAQ)

The key difference lies in the chemical composition and resulting corrosion resistance. Grade 304 stainless steel is the most common and is suitable for most environments, offering excellent corrosion resistance to atmospheric conditions. Grade 316 contains an added element, molybdenum, which significantly enhances its resistance to chlorides (like salt) and other harsh chemicals. Therefore, 316 is the mandatory choice for marine applications, coastal areas, chemical plants, and de-icing salt exposure.

"Pitch" refers to the center-to-center distance between the main load-bearing bars. It's a critical specification. A smaller pitch (e.g., 30mm) results in a stronger, more solid-feeling surface that is better for high-traffic pedestrian areas and can prevent smaller objects from falling through. A larger pitch (e.g., 40mm or 60mm) is more economical and lighter but offers less load capacity and a wider opening.

Load-bearing capabilities are determined through a combination of engineering calculations and physical testing, as outlined in ANSI/NAAMM MBG 531 standards. The capacity depends on the bearing bar height and thickness, the pitch, and the span (the distance between supports). We provide detailed load tables for all our products, showing allowable uniform and concentrated loads for various spans to ensure you select a grating that meets your project's safety requirements.

Absolutely. We specialize in custom fabrication. Using your DXF or DWG files, our facility uses CNC plasma or waterjet cutters to create grating panels in virtually any shape, including circles, rings, and complex multi-sided forms. All cut edges are banded with a flat bar of the same material to ensure structural integrity and a clean, safe edge.

Welded grating is made by forge-welding the cross bars to the bearing bars, creating an extremely strong, one-piece construction ideal for heavy-duty industrial applications. Press-locked grating is manufactured by notching both the bearing and cross bars and then pressing them together under high pressure. This method provides a very clean, architectural appearance with crisp intersections and excellent lateral stability, making it popular for architectural facades and public spaces.

The two main surface finishes are 'Plain' and 'Serrated'. Plain surface grating is smooth and suitable for most general-purpose walkways. Serrated surface grating has small notches cut into the top of the bearing bars, creating an aggressively anti-slip surface. It is highly recommended for any area prone to oil, grease, ice, or excessive moisture to significantly enhance worker safety.

Installation is typically done using specialized grating clips (saddle clips) that fasten the panel to the supporting steel structure. The number and type of clips depend on the load requirements. Maintenance for stainless steel net is minimal. Regular cleaning with water and a mild detergent is usually sufficient to maintain its appearance. In industrial environments, periodic washdowns to remove deposits will ensure the passive layer remains intact and the product's long life is achieved.

"The architectural trend towards industrial aesthetics has elevated materials like stainless steel grating from purely functional components to key design elements. Its combination of form, function, and longevity makes it a premier choice for modern building envelopes and public infrastructure."

- Citation from *Architectural Metals Journal*, Q2 2023. (Reference link: www.archmetalsjournal.com/q2-2023/stainless-trends)"Adherence to established manufacturing and fabrication standards, such as those published by NAAMM, is paramount in ensuring the safety and performance of bar grating systems. Specification of certified materials and verified load data should be a non-negotiable part of the procurement process for any structural application."

- Guidance from the National Association of Architectural Metal Manufacturers (NAAMM). (Reference link: www.naamm.org/mbg/standards-overview)