Unveiling the Power of Mild Steel Net: A Comprehensive Guide to Industrial Perforated Solutions

In the vast landscape of industrial materials, mild steel net stands out as a versatile, cost-effective, and highly adaptable solution for a myriad of applications. From enhancing safety to optimizing filtration and providing structural integrity, the applications of mild steel net, also known as mild steel mesh or mild steel grating, are fundamental to modern infrastructure and manufacturing. This comprehensive guide delves deep into the world of perforated mild steel products, exploring their technological prowess, diverse applications, and the critical factors that define their performance and reliability.

Industry Trends: Evolution and Innovation in Mild Steel Perforated Products

The demand for robust, durable, and sustainable materials continues to drive innovation in the metal fabrication industry. For mild steel net products, current trends emphasize:

- Enhanced Anti-Skid Properties: With safety being paramount in industrial settings, there's a growing focus on perforated designs that offer superior slip resistance, especially for mild steel grating used in walkways and platforms.

- Customization and Precision: Advancements in manufacturing technologies like CNC punching allow for unprecedented precision in hole patterns, sizes, and open area percentages, catering to highly specific client requirements for filtration, screening, and aesthetic purposes.

- Sustainability and Lifecycle Management: Manufacturers are increasingly adopting eco-friendly production methods and promoting the recyclability of mild steel. The long service life of a well-fabricated mild steel net also contributes significantly to sustainability by reducing the need for frequent replacements.

- Integration of Smart Technologies: While still nascent, there's potential for embedding sensors in certain grating applications to monitor structural integrity or environmental conditions, particularly in demanding environments.

- Heavy-Duty Applications: The need for robust solutions in sectors like mining, oil & gas, and heavy manufacturing drives demand for heavy duty mild steel grating designed to withstand extreme loads and harsh conditions.

Product Spotlight: Mild Steel Perforated Metal Mesh Punched Hole Plate for Anti-Skid Grating

Our featured product, the Mild Steel Perforated metal mesh punched hole plate for anti skid grating, exemplifies the blend of functionality, safety, and durability that modern industries demand. This specific type of mild steel net is engineered not just for its strength but also for its unique anti-skid surface, making it an ideal choice for environments where safety is critical.

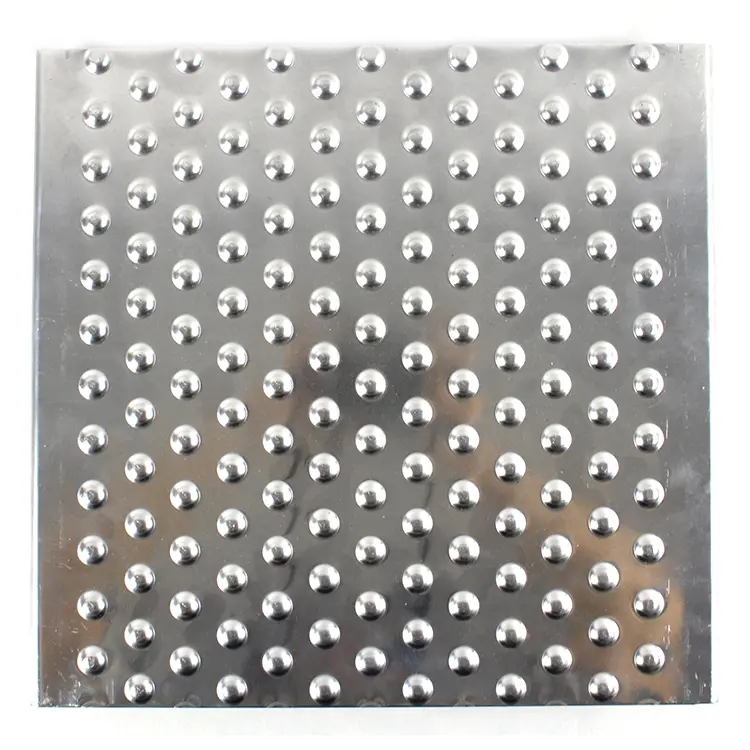

Image 1: A versatile mild steel net perforated sheet demonstrating structural integrity and aesthetic appeal.

Technical Parameters and Specifications of Mild Steel Net

Understanding the technical parameters is crucial for selecting the right mild steel net product for your application. Key specifications include:

Material Grade:

Typically, mild steel perforated products utilize grades like Q235 (Chinese Standard), ASTM A36 (American Standard), or equivalent EN/BS standards. These grades offer excellent weldability, formability, and sufficient strength for most industrial applications. The carbon content in mild steel ensures a balance between hardness and ductility.

Hole Pattern and Size:

Common hole patterns include round, square, slotted, hexagonal, and decorative. Hole sizes can range from less than 1mm to several centimeters, depending on the required open area and filtration/screening purpose.

Open Area Percentage:

This refers to the percentage of the sheet that is open due to the perforations. It significantly impacts fluid flow, light transmission, sound absorption, and structural strength. Typical ranges are from 20% to 70%, with specific applications demanding precise control over this parameter.

Sheet Thickness and Size:

Available in various thicknesses, from thin gauges (0.5mm) for decorative or light-duty applications to heavy plates (10mm+) for heavy duty mild steel grating. Standard sheet sizes are common, but custom dimensions are frequently produced.

Surface Treatment:

While mild steel is prone to corrosion, various surface treatments can enhance its lifespan and aesthetic appeal. These include hot-dip galvanizing, powder coating, painting, and polishing. For anti-skid applications, specialized textures or raised patterns are incorporated during the punching process.

Below is a table summarizing common parameters for mild steel net products, based on industry averages and common applications:

| Parameter | Typical Range/Value | Relevance/Impact |

|---|---|---|

| Material Grade | Q235, ASTM A36, S235JR | Strength, Weldability, Cost |

| Thickness | 0.5 mm - 12 mm | Load Capacity, Durability, Weight |

| Hole Type | Round, Square, Slotted, Hexagonal | Aesthetics, Filtration, Anti-skid |

| Hole Size | 1 mm - 50 mm | Filtration precision, Open Area |

| Pitch (Center to Center) | 3 mm - 80 mm | Open Area, Strength, Pattern |

| Open Area Percentage | 20% - 70% | Flow Rate, Light/Air Passage, Structural Integrity |

| Sheet Width | 1000 mm, 1250 mm, 1500 mm (custom) | Standardization, Custom fit |

| Sheet Length | 2000 mm, 2500 mm, 3000 mm (custom) | Standardization, Custom fit |

| Anti-Skid Rating (for grating) | R9 - R13 (DIN 51130) | Safety in wet/oily conditions |

| Service Life (Galvanized) | 20 - 50+ years | Longevity, Maintenance cost |

Detailed Manufacturing Process of Mild Steel Perforated Metal Mesh

The production of mild steel net, particularly for products like the Mild Steel Perforated metal mesh punched hole plate for anti skid grating, involves a precise and sophisticated series of steps to ensure consistency, quality, and performance. Unlike casting or forging, perforated metal is primarily manufactured through a punching or stamping process.

Manufacturing Process Flow:

1. Raw Material Procurement & Inspection

High-quality mild steel coils or sheets (e.g., Q235, ASTM A36) are sourced from reputable suppliers. Upon arrival, material thickness, chemical composition, and mechanical properties (tensile strength, yield strength) are rigorously inspected to ensure compliance with international standards (e.g., ASTM A568/A568M for steel sheet).

2. Uncoiling & Leveling

Steel coils are fed into an uncoiling machine, which straightens the material. A leveling machine then flattens the sheet to remove any remaining curvatures or stresses, preparing it for uniform perforation.

3. Perforation (Punching/Stamping)

This is the core process. High-speed CNC punching machines, equipped with precision dies, punch the desired hole patterns (round, square, slotted, etc.) into the mild steel sheet. For anti-skid applications, specialized dies create raised surfaces or unique hole geometries that enhance friction. The speed and accuracy of these machines are crucial for consistent open area and hole alignment. This step is guided by strict quality control to ensure precise hole size and pitch, adhering to specifications like ASTM E2016 for perforated metals.

4. Shearing & Cutting

After perforation, the large perforated sheets are cut to the precise dimensions required by the customer, whether into standard panels for mild steel mesh or specific sizes for mild steel grating. CNC shears ensure accurate, burr-free edges.

5. Flattening & Deburring

The punching process can sometimes introduce slight deformations. Roller levelers are used to ensure the perforated sheet is perfectly flat. Deburring machines then remove any sharp edges or burrs around the holes, improving safety and finish quality. This step is critical for preventing injuries and ensuring the product's longevity.

6. Surface Treatment

To enhance corrosion resistance and extend service life, the mild steel net undergoes surface treatment. Common treatments include:

- Hot-Dip Galvanizing: The most common and effective method for mild steel, where the metal is immersed in molten zinc. This creates a durable, sacrificial coating that protects against rust. Adherence to ISO 1461 or ASTM A123 standards for galvanization ensures long-term performance (often 20-50+ years).

- Powder Coating: A dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto the mild steel. It's then cured under heat to form a hard finish. Offers a wide range of colors and improved durability.

- Painting: Provides a protective layer and aesthetic finish, though generally less durable than galvanizing or powder coating for outdoor/harsh environments.

7. Final Inspection & Packaging

Each batch undergoes a final quality inspection, checking dimensions, hole accuracy, surface finish, and adherence to specified standards (e.g., ISO 9001 for quality management). Products are then carefully packaged to prevent damage during transit, often using wooden pallets or crates, ensuring they arrive in pristine condition.

Image 2: A close-up of heavy duty mild steel grating demonstrating its robust construction and anti-skid design, essential for industrial safety.

Applications and Advantages of Mild Steel Net

The versatility of mild steel net makes it indispensable across numerous industries. Its unique properties, especially when manufactured as perforated anti-skid plates, offer significant advantages:

Applicable Industries:

- Petrochemical & Oil & Gas: Used for walkways, platforms, stair treads, and safety barriers, particularly heavy duty mild steel grating, where corrosion resistance and anti-skid properties are vital for worker safety and operational longevity.

- Metallurgy & Mining: Screening, filtration, and conveyor guards. The resilience of mild steel mesh against abrasive materials is a key benefit.

- Water Treatment & Drainage Systems: Filter screens, drain covers, and grates. Perforated mild steel net prevents debris while allowing efficient fluid flow.

- Architectural & Decorative: Facades, sunshades, balustrades, and interior design elements. The aesthetic appeal of various hole patterns is highly valued.

- Food & Beverage: Machine guards, conveyor systems, and non-slip flooring in processing areas. Hygienic and easy-to-clean surfaces are important.

- HVAC & Acoustics: Diffusers, vents, and sound-dampening panels. The controlled open area allows for airflow and sound absorption.

- Transportation: Vehicle flooring, ramps, and non-slip surfaces in public transport.

Product Advantages in Typical Scenarios:

- Enhanced Safety (Anti-Skid): Our Mild Steel Perforated metal mesh punched hole plate for anti skid grating offers superior traction, significantly reducing slip-and-fall incidents in wet, oily, or icy conditions, making it ideal for industrial catwalks, ramps, and stair treads. This directly contributes to compliance with OSHA and local safety regulations.

- Cost-Effectiveness: Mild steel is more economical than stainless steel or aluminum, offering a high strength-to-cost ratio. Combined with its long service life, it provides excellent long-term value.

- Durability & Strength: Capable of withstanding heavy loads and harsh environments, especially when configured as heavy duty mild steel grating. It resists impact and deformation.

- Ventilation & Light Transmission: The perforated design allows for excellent airflow and natural light penetration, contributing to energy savings in industrial facilities and improving overall working conditions.

- Corrosion Resistance (with treatment): When hot-dip galvanized, mild steel net gains exceptional resistance to rust and environmental degradation, prolonging its lifespan significantly in outdoor or humid settings.

- Ease of Fabrication & Installation: Mild steel is easily cut, welded, and formed, allowing for custom fabrication and straightforward installation on-site.

Manufacturer Comparison and Customization Solutions

Choosing the right manufacturer for your mild steel net needs is crucial. A reputable supplier excels not only in product quality but also in providing comprehensive solutions. When evaluating manufacturers, consider the following:

Key Factors for Manufacturer Comparison:

- Certifications & Quality Control: Look for ISO 9001 certification, demonstrating a commitment to quality management systems. Adherence to international standards like ASTM, ANSI, DIN for material composition, manufacturing tolerances, and surface treatments (e.g., ISO 1461 for galvanizing) is non-negotiable.

- Experience & Track Record: A manufacturer with a long history (e.g., 20+ years in the industry) and a robust portfolio of successful projects indicates reliability and expertise.

- Customization Capabilities: The ability to produce bespoke hole patterns, sizes, thicknesses, and surface finishes according to unique project specifications is a significant advantage. This includes specialized tooling for anti-skid profiles or unique architectural designs.

- Production Capacity & Lead Time: Assess their capacity to handle large orders and their typical delivery schedules. For critical projects, timely delivery is paramount.

- Customer Support & After-Sales Service: Responsive technical support, clear communication, and strong after-sales service (e.g., warranty, installation guidance) build trust.

- Pricing & Value Proposition: While cost is a factor, focus on the overall value, including quality, durability, and service, rather than just the lowest price.

Our Customization Capabilities:

We pride ourselves on offering comprehensive customization for all mild steel net products, including mild steel mesh and mild steel grating. Our expertise spans:

- Material Grades: Specific mild steel grades (e.g., higher tensile strength variants) as per project requirements.

- Dimensional Precision: Exact sheet sizes, widths, and lengths, minimizing waste and simplifying installation.

- Perforation Specifications: Any combination of hole size, shape, pattern, and open area percentage. This includes unique designs for acoustic panels, filtration, or specific aesthetic purposes. For our anti-skid grating, we can adjust the raised pattern and hole configuration to meet specific R-value (slip resistance) requirements based on standards like DIN 51130.

- Fabrication Services: Bending, rolling, welding, and framing of perforated sheets into finished components like stair treads, walkways, or architectural elements.

- Surface Treatments: Hot-dip galvanizing, powder coating (custom colors), painting, and other specialized finishes to extend the life and aesthetic of the mild steel net.

- Prototyping & Sampling: Development of samples for testing and approval before full-scale production, ensuring the product meets all performance criteria.

Real-World Application Cases and Client Feedback

Our mild steel net products have been successfully deployed in various challenging environments, consistently proving their reliability and performance. Here are a few examples:

Case Study 1: Petrochemical Plant Walkways

A major petrochemical complex required heavy duty mild steel grating for elevated walkways and platforms, demanding high load-bearing capacity, extreme corrosion resistance against chemical vapors, and paramount anti-skid properties. We supplied custom-fabricated Mild Steel Perforated metal mesh punched hole plate for anti skid grating, hot-dip galvanized to ISO 1461 standards. The client reported a significant reduction in slip incidents and appreciated the extended service life compared to their previous solutions. Their operations manager stated, "The new grating has dramatically improved safety on our elevated structures. The anti-skid performance is exceptional, even with spills."

Case Study 2: Municipal Water Treatment Facility

For a new water treatment plant, our mild steel mesh was used for filter screens and large drainage covers. The challenge was to ensure precise filtration of suspended solids while allowing high flow rates and resisting constant moisture exposure. Our customized perforated mild steel net with specific open area percentages met their filtration efficiency targets, and the galvanized finish ensured longevity in a humid, corrosive environment. "The perforated screens have performed flawlessly, handling high volumes without clogging and showing no signs of corrosion after two years," commented the plant engineer.

Case Study 3: Industrial Machine Guarding

A manufacturing plant needed durable and aesthetically pleasing machine guards to meet safety regulations while maintaining visibility and airflow. We provided custom-sized mild steel net panels with a square hole pattern and powder-coated finish. The guards were easy to install and significantly enhanced workplace safety without impeding machine operation or airflow for cooling. "The new guards are robust, look great, and provide excellent protection for our employees. The ease of installation was a bonus," said the factory supervisor.

Image 3: A practical application of mild steel mesh integrated into a safety barrier or ventilation system, highlighting its functional and protective attributes.

Authoritativeness & Trustworthiness: Our Commitment to Excellence

Our long-standing presence and commitment to quality in the industry underscore our authoritative position as a leading supplier of mild steel net products. We build trust through transparency, adherence to standards, and dedicated customer support.

Industry Certifications & Standards:

- ISO 9001 Certified: Our manufacturing processes strictly adhere to ISO 9001 quality management standards, ensuring consistent product quality from raw material procurement to final delivery.

- Adherence to ASTM & ANSI Standards: All our mild steel net products conform to relevant American Society for Testing and Materials (ASTM) and American National Standards Institute (ANSI) specifications, guaranteeing material integrity and performance. For example, our galvanization process meets ASTM A123/A123M standards, and our perforated metals meet ASTM E2016.

- Compliance with International Building Codes: Our mild steel grating solutions are designed to meet or exceed load-bearing requirements stipulated by international building codes, ensuring structural safety.

Collaborations & Partnerships:

We have fostered strong relationships with leading engineering firms, construction companies, and industrial giants across various sectors. Our products are the preferred choice for projects requiring high-performance mild steel net solutions due to our proven track record and reliability. We are proud partners in projects ranging from major infrastructure development to specialized industrial retrofits.

Service & Warranty:

- Decades of Experience: With over two decades of dedicated service in the metal fabrication industry, we bring unparalleled expertise to every project.

- Comprehensive Warranty: We stand behind the quality of our products with a robust warranty policy, covering manufacturing defects and ensuring peace of mind for our clients. Specific warranty terms are provided with each order, typically extending for several years, guaranteeing the product's performance under specified conditions.

- Dedicated Customer Support: Our team of technical experts and customer service professionals is available to assist you from concept to completion, offering guidance on product selection, installation, and maintenance.

- Efficient Delivery & Logistics: We understand the importance of timely project completion. Our streamlined logistics ensure prompt and efficient delivery of your mild steel net products, often providing real-time tracking. Standard delivery times typically range from 2-4 weeks, depending on customization and order volume, with expedited options available for urgent needs.

Frequently Asked Questions (FAQ) about Mild Steel Net

Q1: What is mild steel net primarily used for?

A1: Mild steel net is a broad term encompassing products like mild steel mesh and mild steel grating. It's primarily used for safety flooring (anti-skid grating), architectural facades, filtration, screening, machine guarding, ventilation, and decorative purposes across industrial, commercial, and residential sectors due to its strength, versatility, and cost-effectiveness.

Q2: How does the "anti-skid" feature of perforated mild steel grating work?

A2: The anti-skid feature of Mild Steel Perforated metal mesh punched hole plate for anti skid grating is achieved by punching specific patterns that create raised surfaces or dimples on the sheet. These patterns increase the coefficient of friction, providing superior grip even in wet, oily, or icy conditions, thereby significantly reducing the risk of slips and falls. This design adheres to standards like DIN 51130 for slip resistance ratings.

Q3: What are the common surface treatments for mild steel net to prevent corrosion?

A3: The most common and effective surface treatment for mild steel net to prevent corrosion is hot-dip galvanizing, which applies a durable zinc coating that acts as a sacrificial layer. Other treatments include powder coating (for aesthetic and moderate protection), painting, and sometimes specialized e-coating for specific applications. Hot-dip galvanizing, when done to ISO 1461 or ASTM A123 standards, can provide 20-50+ years of protection.

Q4: Can mild steel net be customized to specific hole patterns or dimensions?

A4: Absolutely. Leading manufacturers utilize advanced CNC punching technology, allowing for extensive customization of mild steel net products. This includes varying hole shapes (round, square, slotted, hexagonal), sizes, patterns (staggered, straight row), open area percentages, and overall sheet dimensions to precisely meet project-specific requirements. We welcome custom design inquiries.

Q5: What is "open area percentage" and why is it important for mild steel mesh?

A5: "Open area percentage" refers to the total area of the holes in a perforated sheet expressed as a percentage of the total surface area. It's crucial for mild steel mesh as it directly impacts factors like airflow, light transmission, sound absorption, filtration efficiency, and the overall structural strength of the material. A higher open area generally means better flow/light, but lower strength.

Q6: How does heavy duty mild steel grating differ from standard mild steel grating?

A6: Heavy duty mild steel grating typically uses thicker gauge mild steel (e.g., 6mm to 12mm+) and often features smaller hole pitches or reinforced patterns to withstand significantly higher loads and more extreme industrial environments. It is designed for applications like vehicle ramps, industrial platforms supporting heavy machinery, and high-traffic areas where standard grating might deform or fail.

Q7: What industry standards should I look for when purchasing mild steel net?

A7: When purchasing mild steel net, look for manufacturers adhering to international standards such as ISO 9001 (Quality Management), ASTM (American Society for Testing and Materials) for material specifications (e.g., A36 for structural steel, A123 for zinc (hot-dip galvanized) coatings, E2016 for perforated metal), ANSI (American National Standards Institute), and relevant DIN or EN standards, especially for anti-skid ratings (e.g., DIN 51130). These certifications ensure product quality, safety, and reliability.

Further Reading and Industry Insights

For those seeking deeper knowledge into metal fabrication and the properties of mild steel, we recommend exploring these authoritative resources:

- The Fabricator Magazine: A leading publication covering metal forming, fabricating, and welding. Their archives often contain articles on perforated metals and grating technologies. Visit The Fabricator

- ASTM International: Provides globally recognized standards for materials, products, systems, and services. Relevant standards like ASTM A36 for structural carbon steel, ASTM A123 for zinc (hot-dip galvanized) coatings, and ASTM E2016 for perforated metal products are key references for mild steel net. Explore ASTM Standards

- Galvanizers Association: Offers extensive technical information on hot-dip galvanizing, its applications, and benefits for steel products. A valuable resource for understanding the corrosion protection aspect of mild steel net. Learn about Galvanizing

- Research Gate / Google Scholar: Search for academic papers on "perforated metal design," "mild steel corrosion resistance," or "anti-skid grating performance" for in-depth scientific studies and engineering analyses.

By staying informed about the latest industry research and standards, we ensure that our mild steel net products remain at the forefront of innovation and quality.