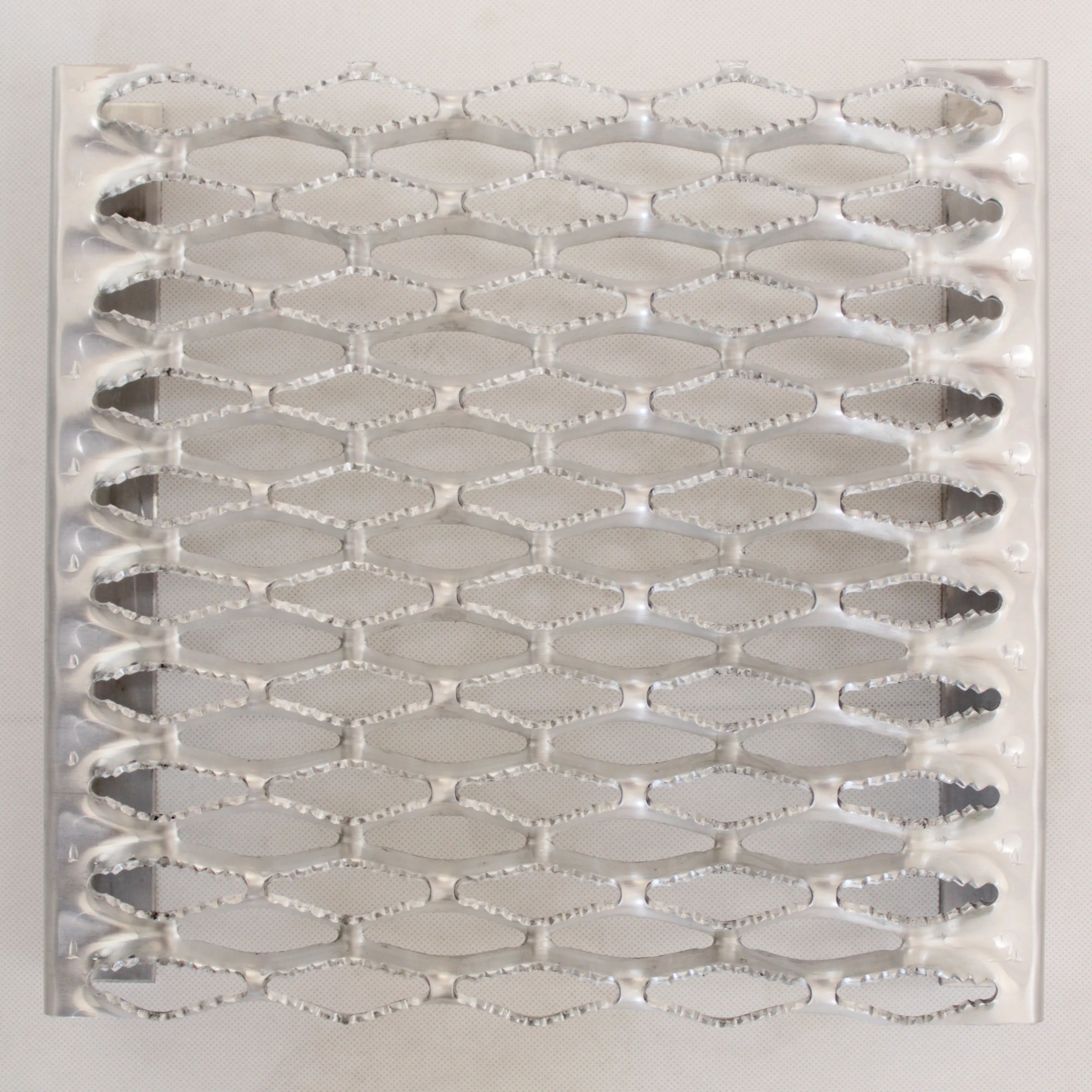

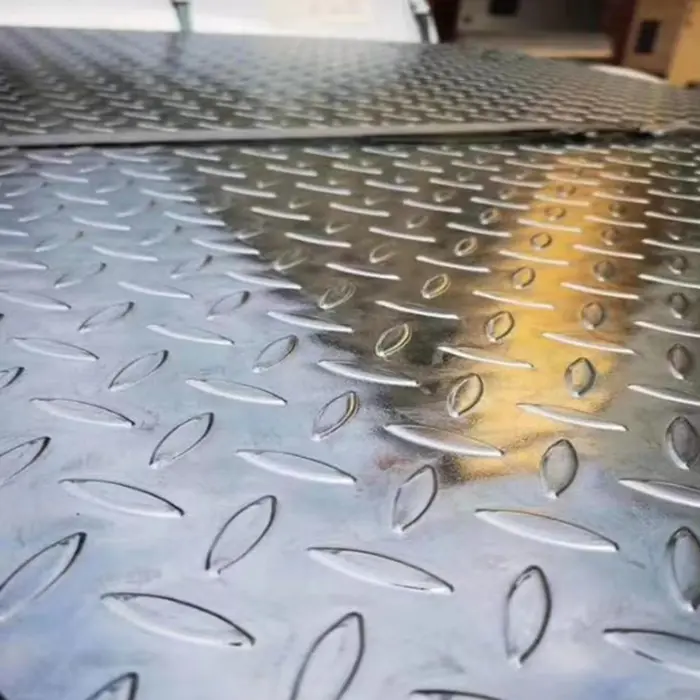

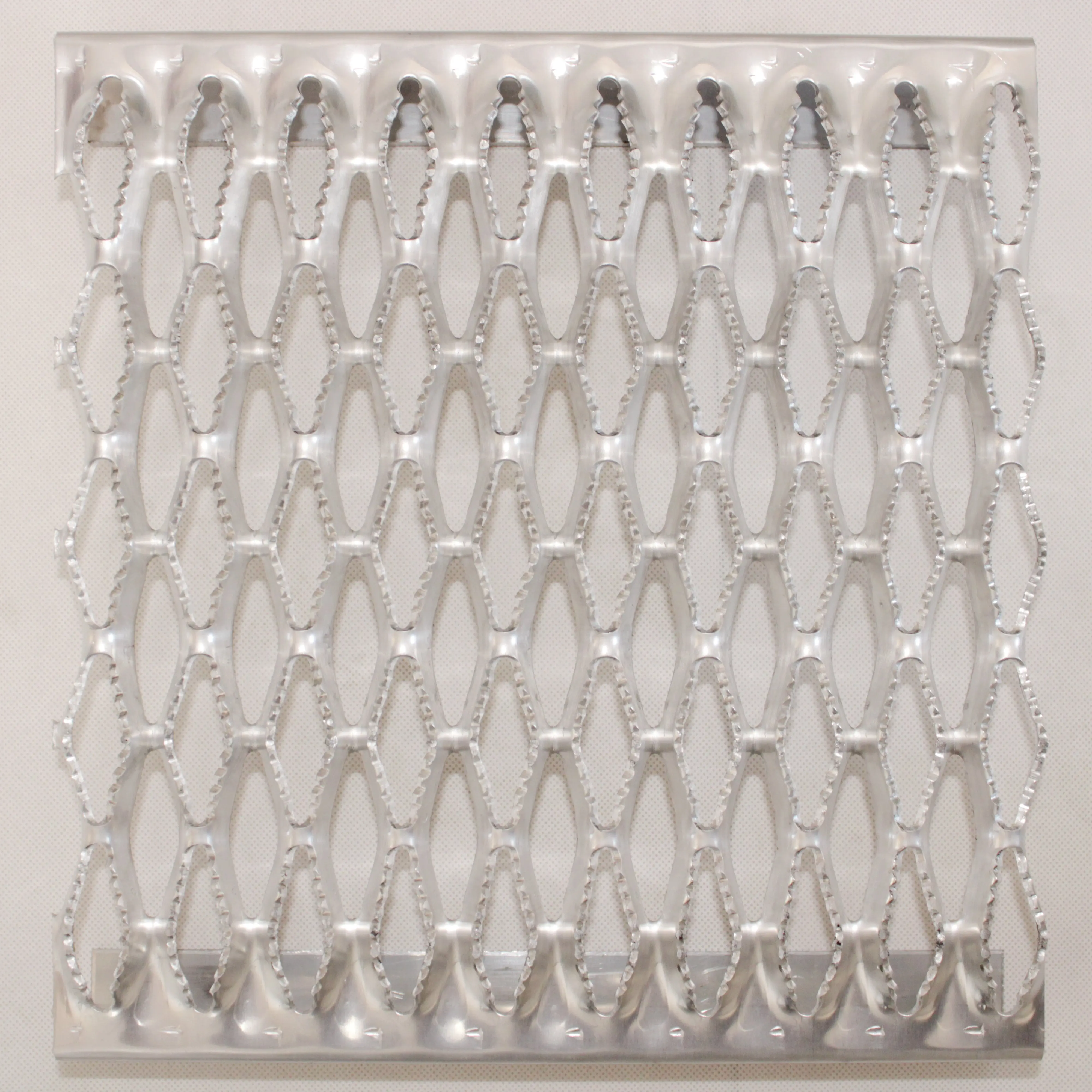

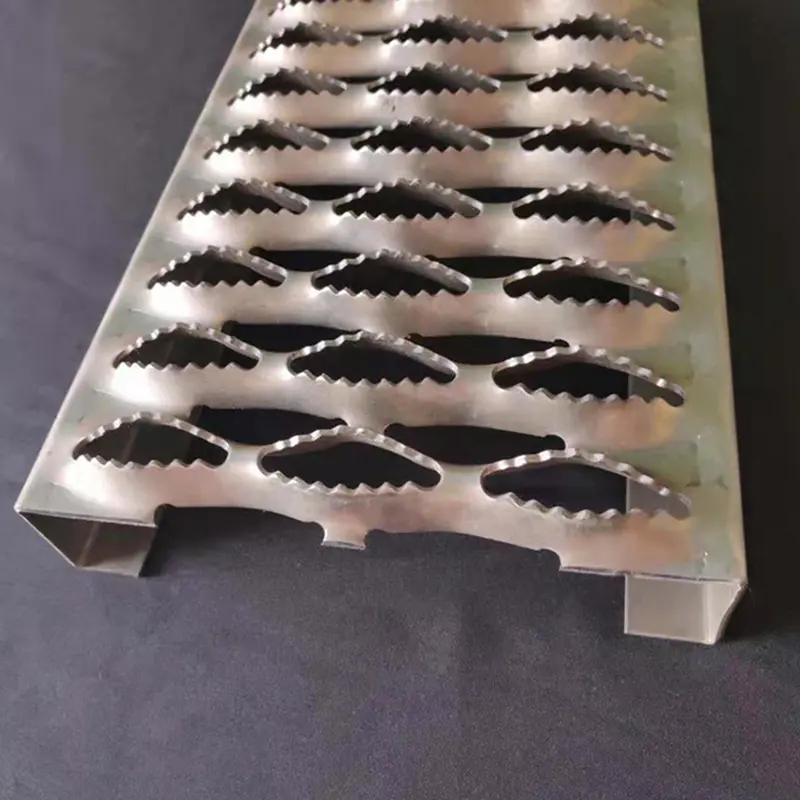

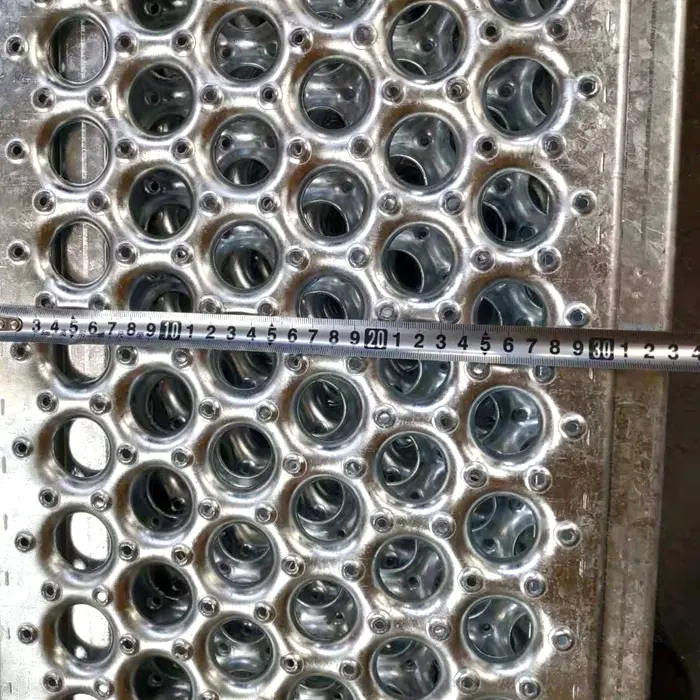

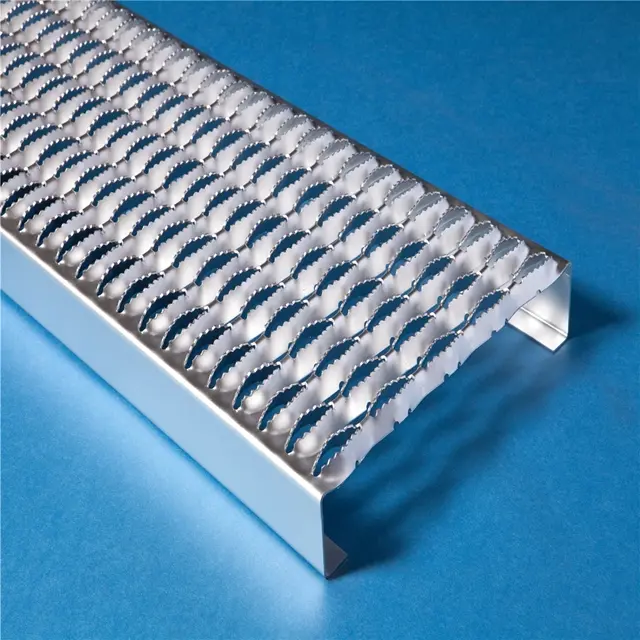

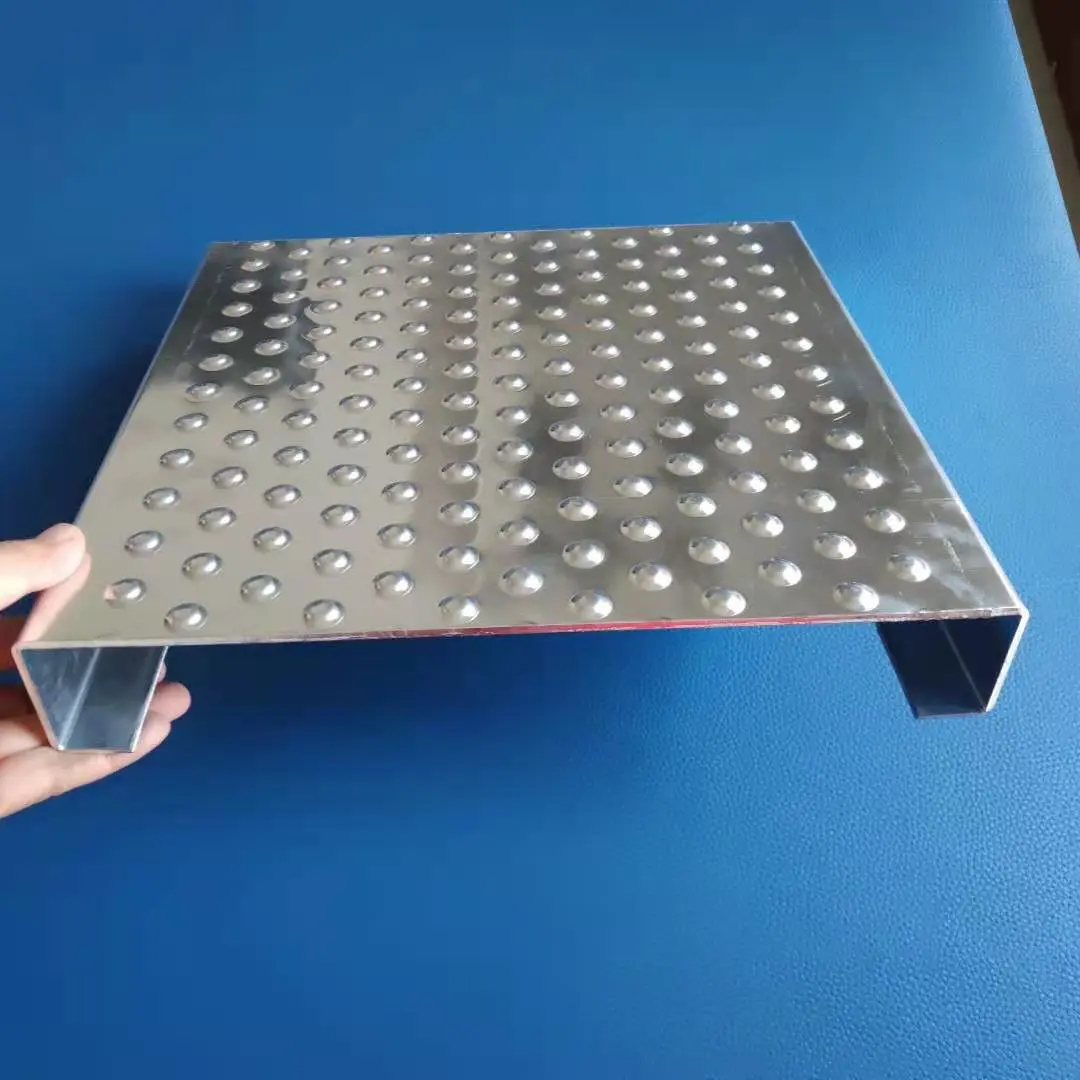

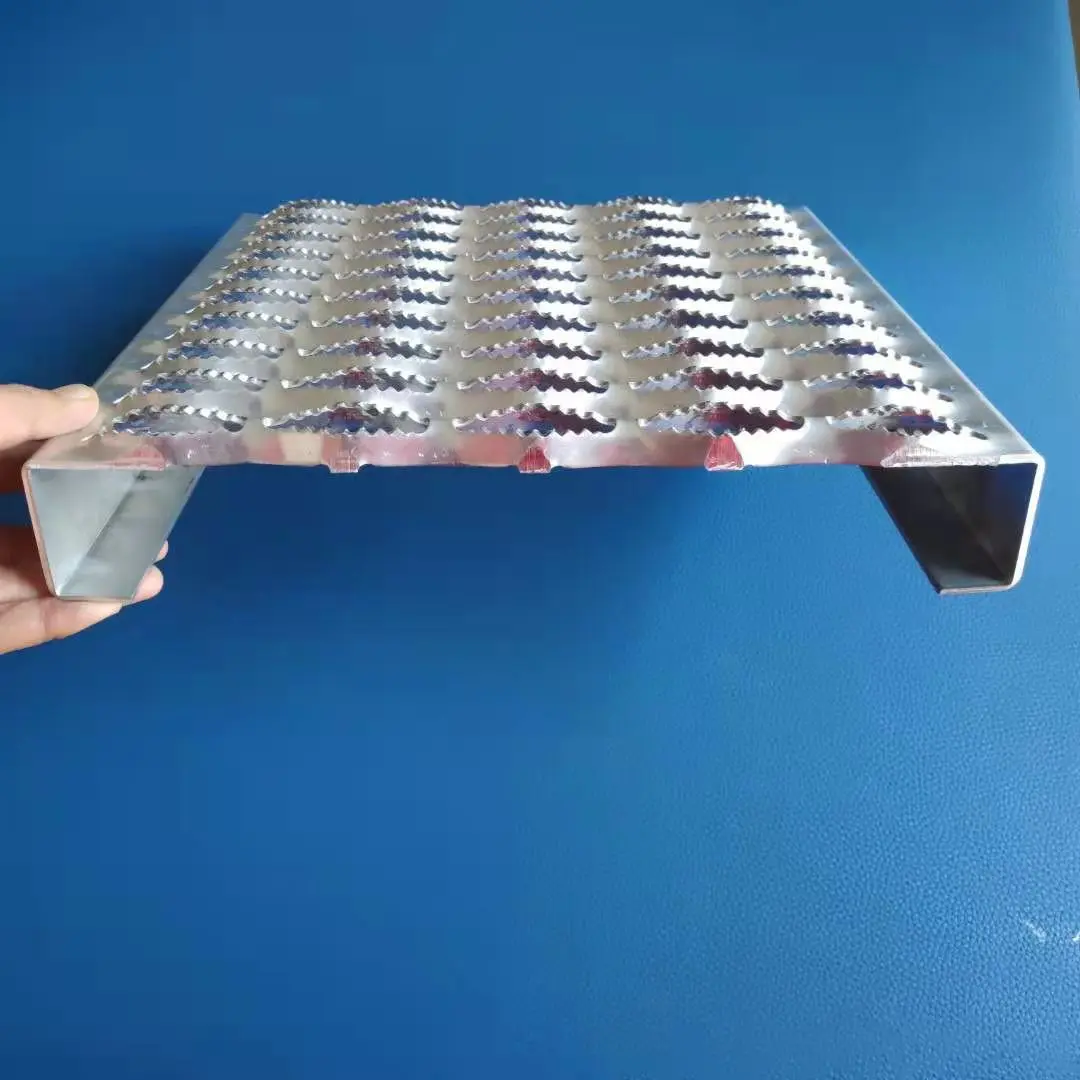

Anti-Skid Plate is a specialized metal plate engineered to provide superior traction and prevent slips in high-risk environments. Typically made from steel, aluminum, or composite materials, its surface features raised patterns, perforations, or textured coatings that create friction underfoot. This design ensures stability even in wet, oily, or muddy conditions, making it indispensable for industrial walkways, vehicle steps, marine decks, and construction platforms.

Beyond safety, anti-skid plates offer durability and resistance to wear, corrosion, and heavy loads. They are often galvanized or coated with anti-rust treatments for long-term use in harsh climates. Versatile in application, these plates are widely used in transportation (truck beds, aircraft stairs), manufacturing facilities, and public infrastructure where slip hazards are a concern. Their combination of functionality and ruggedness makes them a critical component in workplace safety systems.

What is the Purpose of an Anti-Skid Plate?

An anti-skid plate is designed to enhance traction and prevent slips or falls in environments where surfaces may become slippery due to oil, water, grease, or weather conditions. Commonly made from steel, aluminum, or composite materials, these plates feature textured surfaces, raised patterns, or specialized coatings to improve grip underfoot.

Anti-skid plates are widely used in industrial facilities, marine decks, vehicle running boards, and construction platforms where worker safety is critical. They help reduce workplace accidents while maintaining durability under heavy foot traffic or equipment movement. The plates also resist wear and corrosion, ensuring long-term performance in harsh conditions. By combining safety and structural integrity, anti-skid plates are essential for high-risk environments requiring reliable slip prevention.

Anti-skid plates employ various coatings and surface treatments to maximize traction and durability. Grit coatings, such as carborundum or epoxy-based finishes, create a rough surface that improves grip even when wet. Hot-dip galvanizing adds corrosion resistance, ideal for outdoor or marine applications.

For specialized needs, powder-coated or polyurethane finishes provide additional chemical resistance and color customization, while diamond plate or serrated patterns enhance mechanical slip resistance. Some advanced treatments include ceramic or thermoplastic coatings for extreme environments like oil rigs or food processing plants.

These treatments not only boost safety but also extend the plate’s lifespan by preventing rust, abrasion, and chemical damage. The choice depends on environmental exposure, load requirements, and industry regulations.