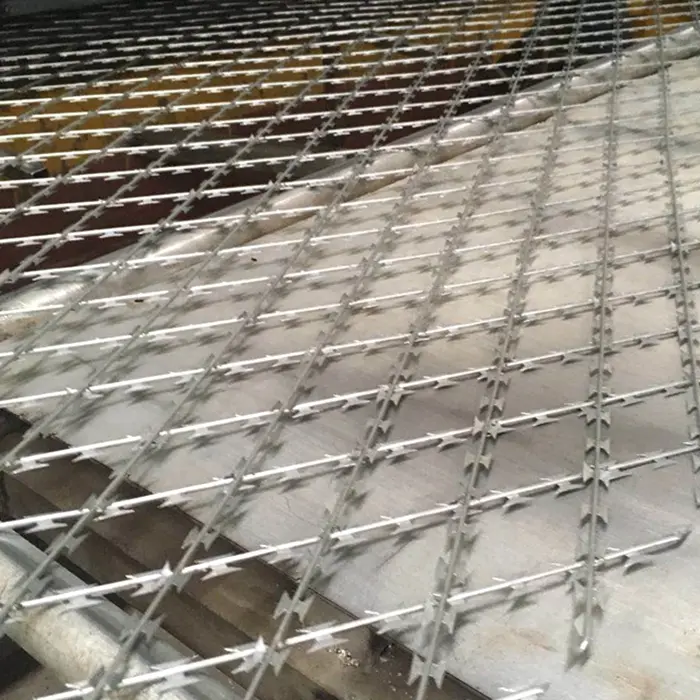

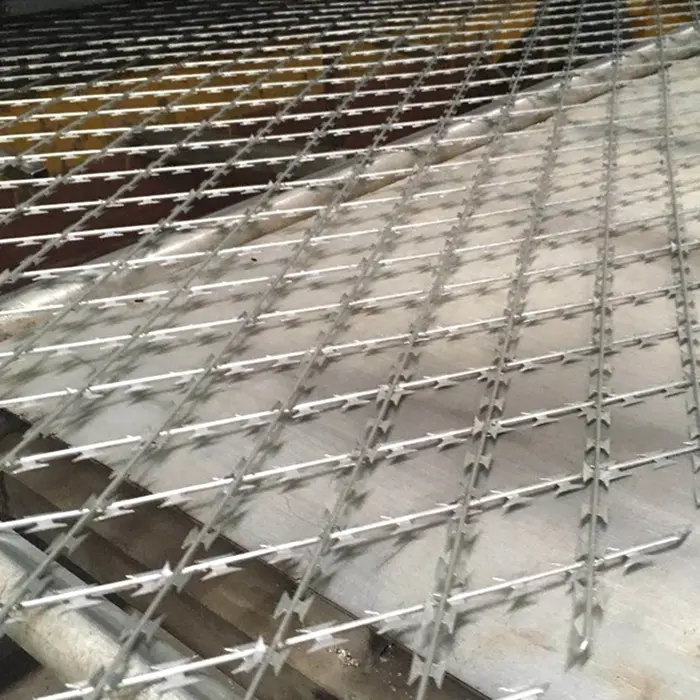

La valla de soldadura se refiere al proceso de construcción vallas metálicas using welding techniques to join individual components, such as rails, posts, and panels. This method ensures a strong, durable, and long-lasting structure, making it ideal for security, privacy, and boundary demarcation. Typically made from materials like steel, iron, or aluminum, welded fences are resistant to weathering, corrosion, and physical impact, especially when treated with protective coatings like galvanization or powder coating. Their robust construction and adaptability make them a preferred choice for perimeter fencing solutions in both commercial and industrial settings.

Compared to prefabricated or bolted fences, high security perimeter fencing like welded fence provides superior strength and stability, making them suitable for high-security areas like prisons, military sites, or industrial facilities. Additionally, their aesthetic appeal allows for decorative designs, blending functionality with visual appeal. Proper installation and maintenance ensure that perimeter security fence solutions remain robust and effective for decades, offering long-term reliability and peace of mind.

¿Cuánto tiempo durará una cerca de alambre soldado?

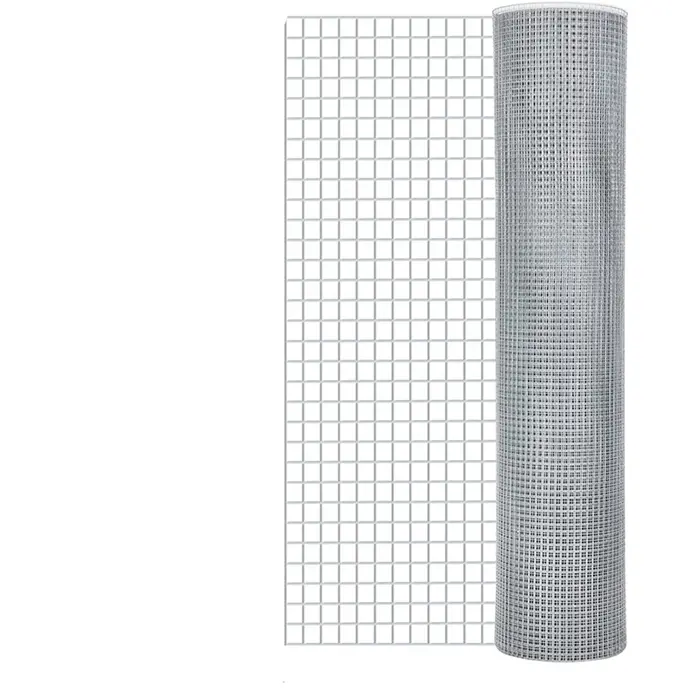

A welded wire fence typically lasts between 15 to 30 years, depending on material quality, environmental conditions, and maintenance. Fences made from galvanized steel tend to last the longest (20-30 years) due to their rust-resistant coating, while non-galvanized or lower-quality wire may deteriorate in 10-15 years. Powder-coated fences offer additional protection against corrosion and UV damage, extending their lifespan further. For enhanced durability and corrosion resistance, consider using stainless steel welded wire mesh panels, which provide superior strength and longevity even in harsh environments.

Harsh weather, such as heavy rain, snow, or coastal salt air, can accelerate rust and weaken the fence over time. Regular inspections for rust, loose welds, or bent wires help prolong its durability. If damage occurs, prompt repairs—such as applying rust-resistant paint or replacing broken sections—can prevent further degradation. Proper installation, including secure posts and tensioning, also plays a key role in longevity. For applications requiring lightweight yet durable fencing, PVC weld mesh offers an excellent alternative, combining flexibility with resistance to environmental wear. Overall, with good maintenance and the right material choice, a welded wire fence can remain functional and sturdy for decades.

¿Cómo mantener tensa una cerca de alambre soldado?

Para mantener una cerca de alambre soldado bien ajustada, es fundamental una instalación correcta y ajustes periódicos. Comience por asegurar postes resistentes y bien anclados (de metal o madera tratada), separados a una distancia máxima de 2,4 a 3 metros (8-10 pies) para evitar que se deformen. Tensar la malla firmemente durante la instalación con un tensor o una herramienta de arrastre ayuda a eliminar la holgura.

Con el tiempo, el clima y la pérdida de tensión pueden provocar que la cerca se afloje. Reajustar el alambre con bandas de tensión o grapas puede restaurar su firmeza. Añadir rieles de soporte horizontales entre los postes también ayuda a distribuir la tensión uniformemente. Para mayor estabilidad, asegure la parte inferior de la cerca con estacas de tierra o un alambre de tensión para evitar que los animales o los escombros la empujen hacia afuera. Las inspecciones regulares y los pequeños ajustes garantizan que la cerca se mantenga tensa y segura durante años.