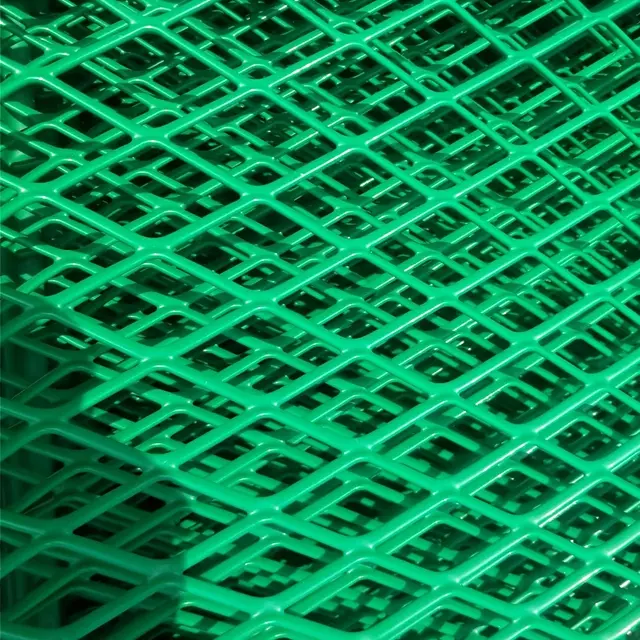

Welding fence refers to the process of constructing metal fences using welding techniques to join individual components, such as rails, posts, and panels. This method ensures a strong, durable, and long-lasting structure, making it ideal for security, privacy, and boundary demarcation. Typically made from materials like steel, iron, or aluminum, welded fences are resistant to weathering, corrosion, and physical impact, especially when treated with protective coatings like galvanization or powder coating.

Compared to prefabricated or bolted fences, welded fences provide superior strength and stability, making them suitable for high-security areas like prisons, military sites, or industrial facilities. Additionally, their aesthetic appeal allows for decorative designs, blending functionality with visual appeal. Proper installation and maintenance ensure a welded fence remains robust and effective for decades.

How Long Will a Welded Wire Fence Last?

A welded wire fence typically lasts between 15 to 30 years, depending on material quality, environmental conditions, and maintenance. Fences made from galvanized steel tend to last the longest (20-30 years) due to their rust-resistant coating, while non-galvanized or lower-quality wire may deteriorate in 10-15 years. Powder-coated fences offer additional protection against corrosion and UV damage, extending their lifespan further.

Harsh weather, such as heavy rain, snow, or coastal salt air, can accelerate rust and weaken the fence over time. Regular inspections for rust, loose welds, or bent wires help prolong its durability. If damage occurs, prompt repairs—such as applying rust-resistant paint or replacing broken sections—can prevent further degradation. Proper installation, including secure posts and tensioning, also plays a key role in longevity. Overall, with good maintenance, a welded wire fence can remain functional and sturdy for decades.

How Do You Keep a Welded Wire Fence Tight?

To maintain a tight welded wire fence, proper installation and periodic adjustments are crucial. Start by ensuring strong, well-anchored posts (metal or treated wood) spaced no more than 8-10 feet apart to prevent sagging. Stretching the mesh tightly during installation using a fence stretcher or come-along tool helps eliminate slack.

Over time, weather and tension loss may cause the fence to loosen. Re-tightening the wire with tension bands or wire clips can restore firmness. Adding horizontal support rails between posts also helps distribute tension evenly. For extra stability, secure the bottom of the fence with ground stakes or a tension wire to prevent animals or debris from pushing it outward. Regular inspections and minor adjustments ensure the fence remains taut and secure for years.