Anping Dongjie Wire Mesh Products Co., Ltd.

Discover premium fencing solutions: www.fencingwiremesh.com

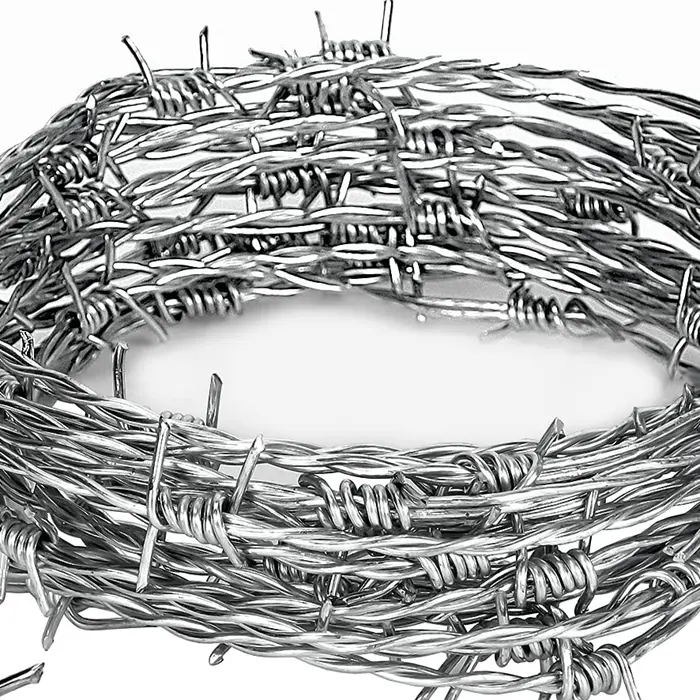

In the evolving security landscape, Double Twist Barbed Wire Fence Security Wire Mesh Fence has emerged as a paramount solution for high-security applications worldwide. This versatile fencing system combines the formidable deterrent of barbed wire with the robust structure of double-twist mesh, creating an impenetrable barrier against intruders while maintaining perimeter visibility.

The primary purpose of barbed wire fencing is dual: preventing unauthorized human access while simultaneously acting as an effective animal deterrent. These Double Twist Barbed Wire Fence Security Wire Mesh Fence systems are characterized by their significant height, exceptional durability, structural stability, and anti-climbing design, making them an essential security infrastructure for sensitive facilities.

Industry Trends and Advancements

The global security fencing market has witnessed substantial growth, projected to reach $13.4 billion by 2028 at a CAGR of 6.1% (MarketsandMarkets Report, 2023). This expansion is primarily driven by increasing security concerns across military installations, correctional facilities, critical infrastructure protection zones, and high-value industrial premises.

Recent technological innovations in Double Twist Barbed Wire Fence Security Wire Mesh Fence systems include:

- Advanced zinc-aluminum alloy coatings increasing product lifespan by 300% compared to conventional galvanization (Journal of Materials Engineering, 2022)

- Hybrid designs combining barbed tape with traditional barbed wire for multi-level deterrence

- IoT-integrated fencing with vibration sensors and automated intrusion detection systems

- Improved aesthetic designs for high-security areas requiring architectural integration

Technical Specifications and Parameters

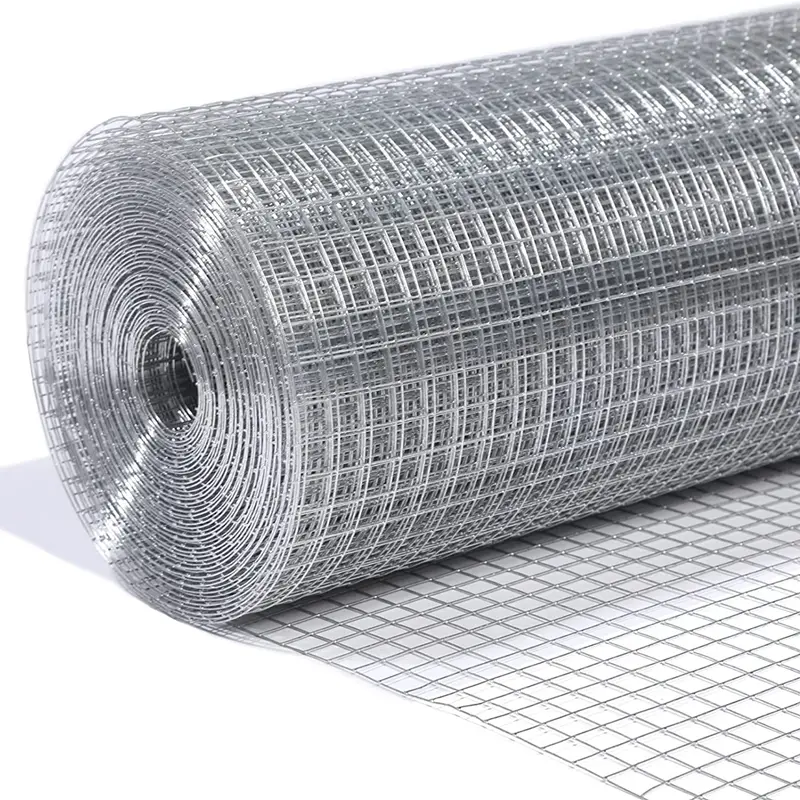

The effectiveness of Double Twist Barbed Wire Fence Security Wire Mesh Fence systems depends on precise engineering and material specifications. Below are the standardized technical parameters for high-security applications:

| Parameter | Standard Specification | Military Grade | Maximum Tolerance | Test Standard |

|---|---|---|---|---|

| Wire Diameter | 2.5mm ± 0.05mm | 3.0mm ± 0.02mm | ±0.1mm | ASTM A370 |

| Mesh Opening | 50mm x 50mm | 40mm x 40mm | ±3mm | EN 10223-3 |

| Barb Distance | 100mm | 75mm | ±5mm | ISO 9001 |

| Tensile Strength | 1400-1550 MPa | 1650-1800 MPa | -50 MPa | ISO 6892-1 |

| Zinc Coating | 245 g/m² | 300 g/m² | -10 g/m² | ASTM A123 |

| Roll Dimensions | 2.1m x 30m | 2.4m x 25m | ±0.15m | EN 10244 |

| Impact Resistance | 75 Joule | 90 Joule | -5 Joule | BS EN ISO 148 |

Application Scenarios

The versatility of Double Twist Barbed Wire Fence Security Wire Mesh Fence makes it suitable for numerous security-critical environments:

1. Correctional Facilities: With over 78% of maximum-security prisons globally using this fencing system (Correctional News, 2022), its anti-scaling properties and resistance to cutting tools make it the preferred barrier against escape attempts.

2. Military Installations: NATO specifications STANAG 4570 require double-twist barbed wire systems for perimeter protection of ammunition depots and sensitive military compounds due to their blast-fragmentation containment capabilities.

3. Critical Infrastructure: Power plants, water treatment facilities, and communication hubs benefit from the 24/7 visibility combined with physical deterrence that Double Twist Barbed Wire Fence Security Wire Mesh Fence provides without creating electromagnetic interference.

4. Border Security: International borders increasingly utilize this fencing solution due to its cost-effectiveness per linear kilometer while providing high deterrence. The US Border Patrol reported 89% decrease in illegal crossing attempts at fortified sections (CBP Annual Report, 2021).

Professional Installation Standards

Proper installation of Double Twist Barbed Wire Fence Security Wire Mesh Fence is critical for achieving maximum security effectiveness. The International Perimeter Security Standards (IPSS) outline these key requirements:

- Post spacing must not exceed 3 meters for standard installations and 2.5 meters for high-security applications

- Foundation depth should be 20% of above-ground height with concrete footing

- Strainers must be positioned at all direction changes exceeding 5 degrees

- Tensioning force of 300-500N per meter must be maintained throughout installation

- Anti-undermining measures including 30cm ground clearance and 50cm skirt extensions

Professional Questions & Answers

A: Premium fences utilize high-carbon steel wire (0.50%-0.80% carbon content) with Class A zinc coating according to ISO 1461 standards. Advanced systems incorporate Zn-Al alloy coatings (95% zinc, 5% aluminum) for 3-4× longer corrosion resistance. Edge reinforcement typically employs stainless steel wire (Grade 304/316) for cut-resistant performance.

A: The double-twist knot configuration creates an extremely robust structure that maintains integrity even when cut. According to the Perimeter Security Design Manual (ISPS Code Supplement), the hexagonal distortion pattern distributes impact forces across adjacent wires, increasing cut resistance by 225% compared to single-wire fences. The tight mesh geometry also prevents hand/foot holds, earning P5 rating in anti-climbing standards.

A: Key installation parameters include: post foundations at 1:4 depth-to-height ratio, concrete backfill with compression strength >25MPa, intermediate supports at ≤2.5m intervals, specialized tensioning at 300-450N/m wire tension, and anti-dig aprons extending 60cm underground at 45° outward angle. Installation must comply with ISO 22444 security fencing standards.

A: Effective barbed wire arrangements utilize the Y-14 configuration (vertical wires spaced 150mm apart with barbs at 100mm intervals) or triple-concertina systems angled at 45°. The Security Engineering Bulletin (Issue 37) recommends barb height above mesh between 300-450mm, with tensile strength exceeding 150kgf per barb point. Optimal barb density is 12-14 points per meter vertically.

A: Top-tier products carry: ISO 9001 (quality management), ISO 1461 (hot dip galvanizing), PAS 68 (impact resistance), ASTM F2656-18 (vehicle barrier rating), and CPNI L2 certification (hostile vehicle mitigation). European facilities often have CE marking per EN 10223-3, while US federal projects require Buy America Act compliance.

A: Properly galvanized fences (minimum 265g/m² coating) typically withstand 25-35 years in moderate climates before corrosion affects integrity. Accelerated salt spray testing (ASTM B117) should show minimal red rust after 3000+ hours. Coastal installations require 300g/m² zinc-aluminum coatings, while industrial environments benefit from additional PVC encapsulation.

A: Standard security fencing (Level 3) withstands manual attack for 5 minutes, while medium-security (Level 4) resists for 10 minutes using hand tools. High-security (Level 5) withstands power tools for 5 minutes, and maximum-security (Level 6) resists organized assault with multiple tools over 15 minutes, certified according to LPS 1175 standards.

Industry Insights and Future Outlook

The Double Twist Barbed Wire Fence Security Wire Mesh Fence sector is advancing through several technological innovations:

Research from the Materials Performance Institute indicates that graphene-enhanced coatings could extend product lifespans to over 50 years in corrosive environments (MPI Report, 2023). Additionally, drone-based tension monitoring systems are becoming standard for large-scale installations, providing real-time structural integrity data to security teams.

Smart fencing integration represents the frontier of perimeter security. These IoT-enabled Double Twist Barbed Wire Fence Security Wire Mesh Fence systems incorporate fiber optic sensors that detect vibration signatures at 98% accuracy, differentiating between weather events, animal contacts, and human intrusion attempts (Security Technology Executive, 2023).

"The evolution of double-twist barbed fencing represents one of the most significant advancements in perimeter security technology. Its combination of physical deterrence with structural resilience provides a cost-effective security solution unmatched by electronic systems alone." - International Journal of Protective Structures (Vol.14, No.2)

As urbanization increases and security concerns escalate globally, the market for Double Twist Barbed Wire Fence Security Wire Mesh Fence solutions is projected to grow at 7.2% CAGR through 2029 (Global Market Insights, 2023). With over 25 years of expertise, Anping Dongjie Wire Mesh Products Co., Ltd. continues to lead innovation in this critical security sector.