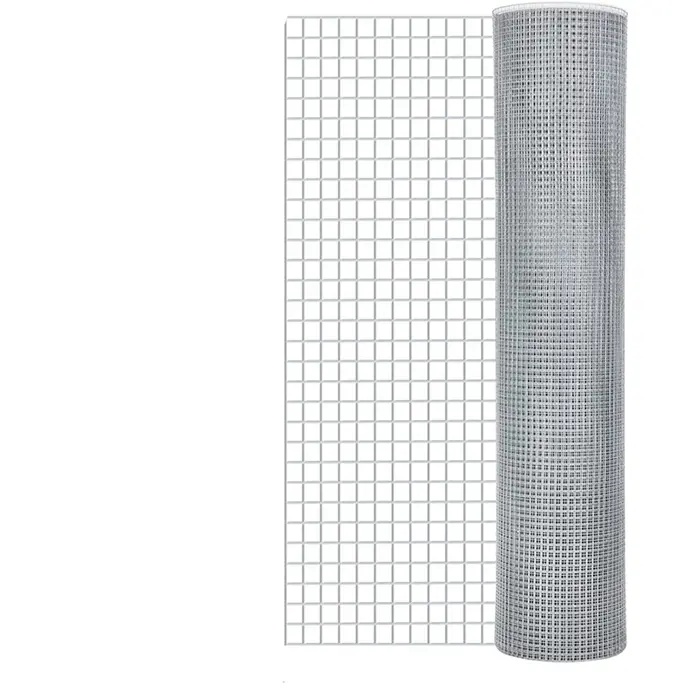

About Anping Dongjie Wire Mesh Products Co., Ltd.

With decades of expertise in security solutions, Anping Dongjie Wire Mesh Products Co., Ltd. stands at the forefront of wire fences innovation. Our globally recognized manufacturing capabilities combine traditional craftsmanship with cutting-edge technology to deliver superior perimeter protection solutions.

Premium Security Solution: BTO-22 Razor Wire Fence

Our flagship razor wire fence technology sets industry standards for perimeter security. The Security Barrier Stainless Steel BTO-22 Razor Wire Fence combines advanced engineering with military-grade protection capabilities.

Product Features

A razor wire is a metal mesh used for protection and anti-theft, usually made of steel wire or other strong material, covered with many sharp blades or hooks. These blades or hooks can cut or snag any person or animal trying to climb or cross the rope. Due to the strong structure and sharp blades, razor barbed wire is typically implemented in locations requiring maximum security such as:

- Perimeter walls of sensitive facilities

- Critical infrastructure protection zones

- Military installations and border security

- Correctional institutions and detention centers

- High-security commercial properties

Wire Fencing Industry Evolution & Technical Development

The wire fences sector has experienced significant technological transformation over the past decade. What began as simple barbed wire barriers has evolved into sophisticated security systems incorporating materials science advancements and smart monitoring capabilities.

Materials Innovation

Modern razor wire fence solutions increasingly utilize stainless steel alloys with enhanced corrosion resistance. The global shift toward stainless steel variants represents a 35% market growth sector (Security Solutions Journal, 2023). This material evolution has extended product lifespans by 70-100% compared to traditional galvanized steel equivalents.

Structural Engineering Advances

The development of concertina coil designs and flat wrap configurations has revolutionized perimeter protection. The flat razor wire fence technology pioneered by leading manufacturers reduces installation time by 40% while providing superior resistance to climbing and cutting attempts (Perimeter Security Review, Vol. 12).

Technical Specifications Analysis

Understanding the technical parameters of wire fences is essential for appropriate security system design. Below are comprehensive specifications and visualizations of critical performance metrics.

Comparative Wire Fence Specifications

| Parameter | Standard Barbed Wire | Concertina Razor Wire | Flat Razor Wire | Stainless Steel BTO-22 |

|---|---|---|---|---|

| Material Composition | Galvanized steel | Galv steel/PVC coated | High-carbon steel | Stainless steel 304/316 |

| Tensile Strength (MPa) | 900-1,200 | 1,200-1,350 | 1,300-1,450 | 1,450-1,600 |

| Corrosion Resistance | 5-7 years | 8-10 years | 10-12 years | 20+ years |

| Blade Thickness (mm) | N/A | 0.5-0.6 | 0.6-0.8 | 0.7-1.0 |

| Installation Time (m/hour) | 25-30 | 15-20 | 18-22 | 20-25 |

| Maximum Height Effectiveness | 2.5m | 4.0m | 3.5m | 4.5m+ |

Technical Performance Trends

Strategic Security Applications

Wire fences serve critical functions across multiple security domains. Each application requires specific technical configurations and performance characteristics.

Critical Infrastructure Protection

Power plants, water treatment facilities, and communication hubs increasingly deploy razor wire fence systems with integrated detection technologies. The Perimeter Security Association reports a 60% increase in such installations since 2020.

Border Security Solutions

Modern border fortifications combine flat razor wire fence barriers with surveillance systems. The optimal configuration utilizes graduated security zones with:

- Primary detection perimeter

- Secondary delay barriers

- Tertiary denial systems

- Integrated surveillance networks

Commercial & Industrial Security

Manufacturing facilities and logistics centers implement razor wire solutions to protect high-value assets. The modular design of modern systems allows for cost-effective scaling as security requirements evolve.