Construction Mesh refers to a versatile category of engineered mesh materials widely used in building and civil engineering projects for reinforcement, safety, and structural support. Typically fabricated from metals (such as steel or aluminum), plastics, or composite materials, these meshes come in various weaves, gauges, and coatings to suit specific applications. A key function includes reinforcing concrete structures—steel rebar mesh, for instance, enhances tensile strength in slabs, pavements, and foundations to prevent cracking.

Durable and corrosion-resistant variants ensure longevity in harsh environments, such as coastal areas or industrial zones. Easy to install and adaptable to complex designs, construction mesh balances functionality with cost-efficiency, making it indispensable in modern infrastructure. Its applications span from temporary site enclosures to permanent architectural features, underscoring its role in both structural integrity and safety compliance.

What is Mesh in Construction?

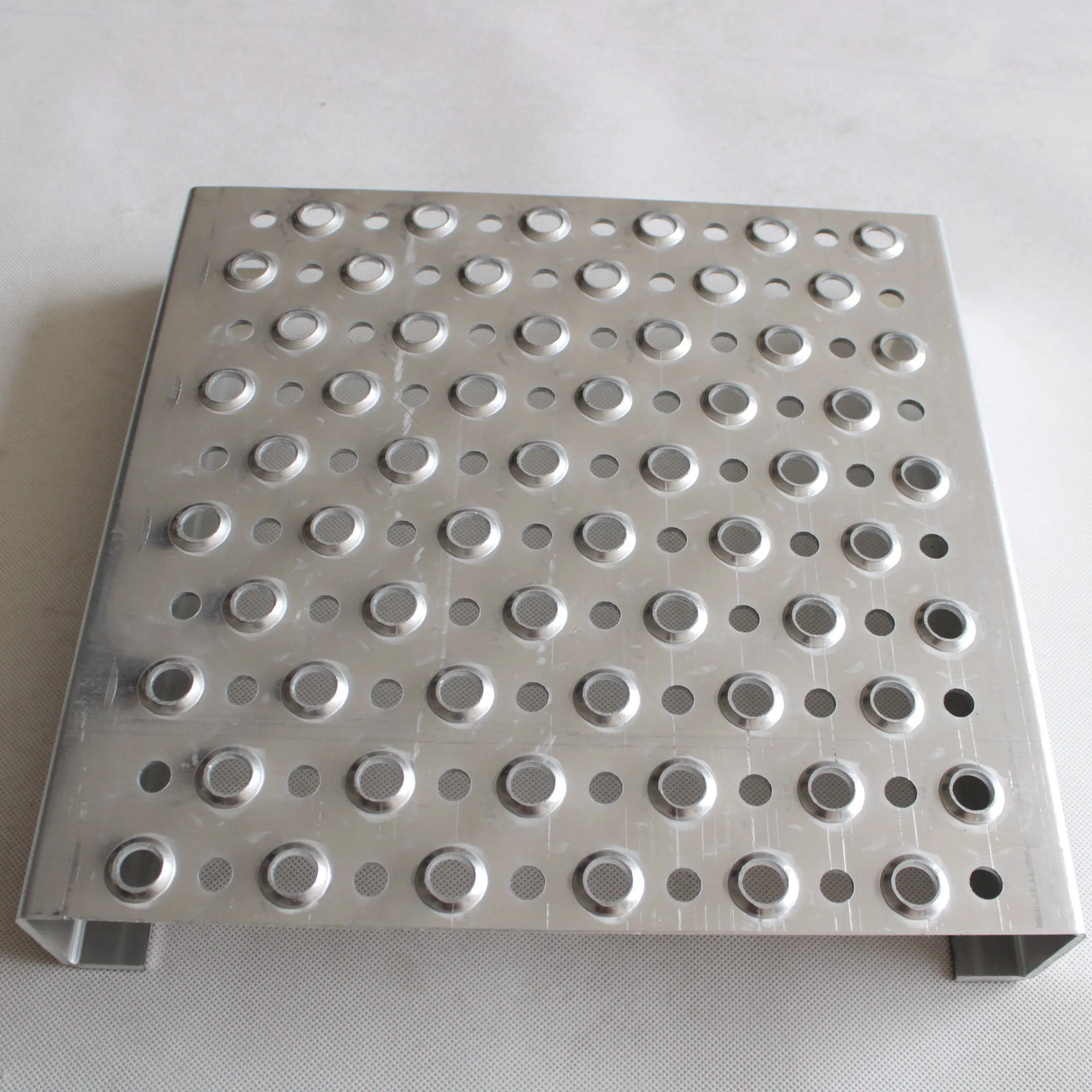

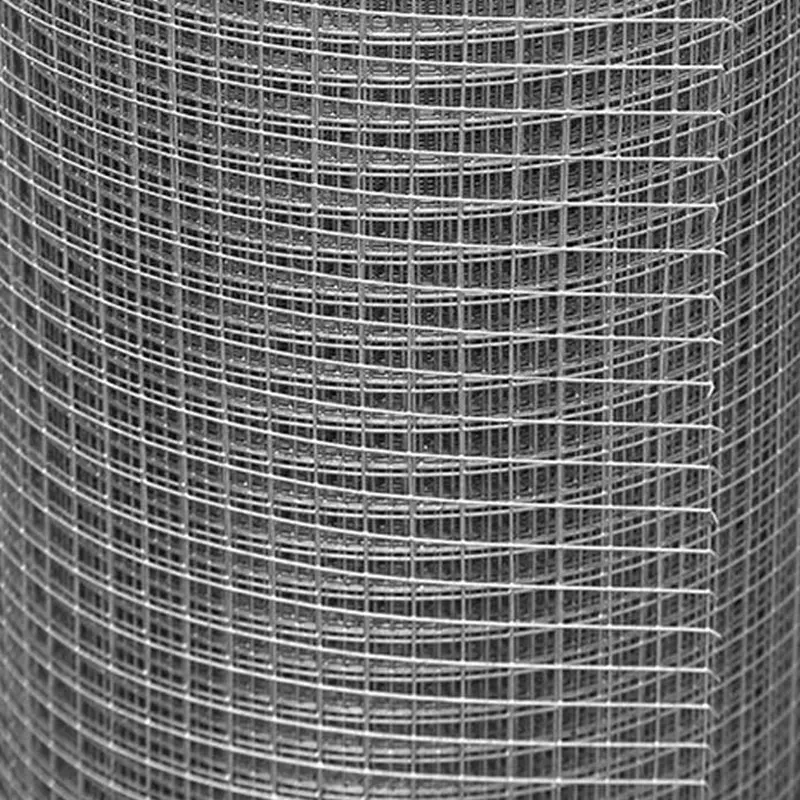

In construction, reinforced concrete wire mesh refers to a grid-like material made from interconnected wires, fibers, or other durable elements, used to reinforce, protect, or partition structures. Common types include welded wire mesh, expanded metal mesh, and fiberglass mesh, each serving specific purposes.

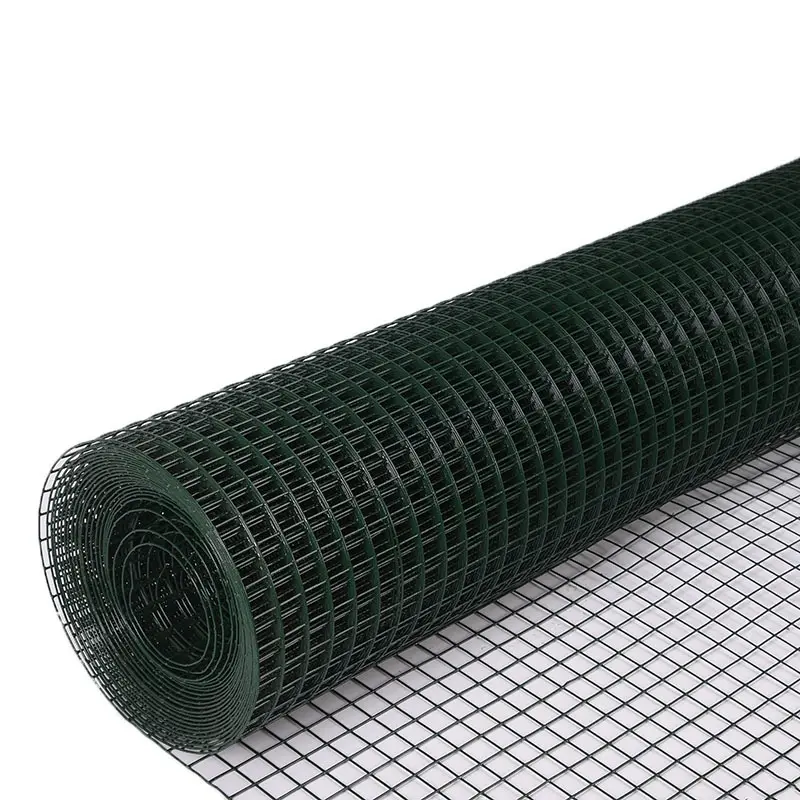

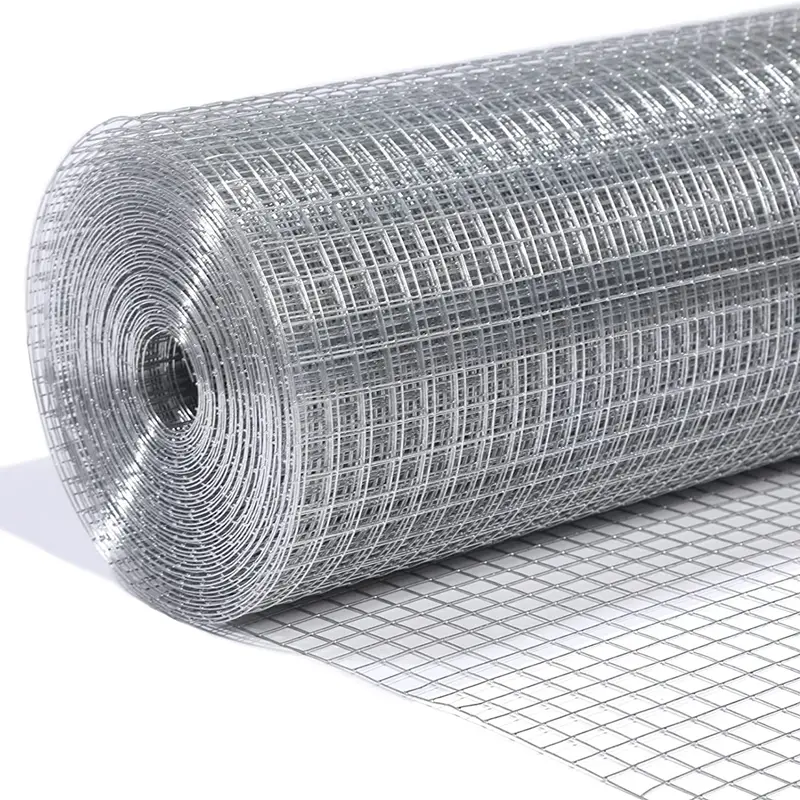

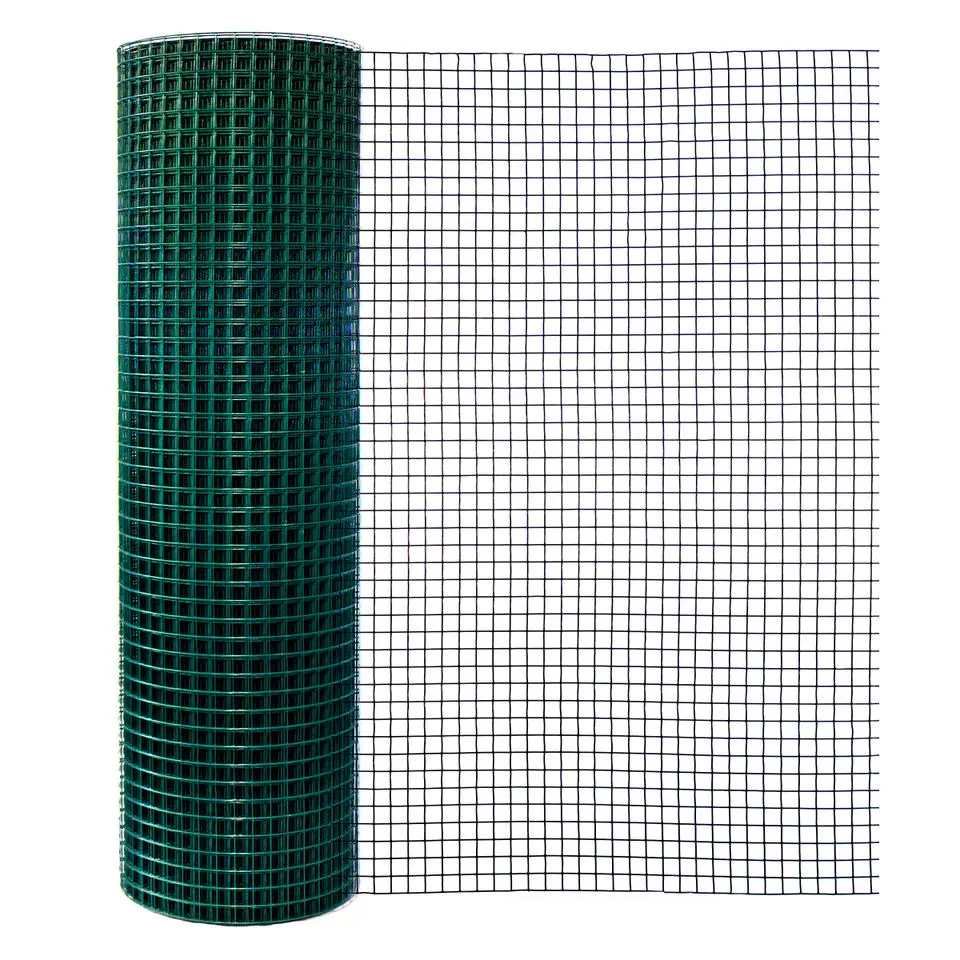

Welded wire mesh, made from steel wires welded at intersections, is widely used in concrete reinforcement, fencing, and masonry to enhance tensile strength and prevent cracking. Expanded metal mesh, formed by cutting and stretching metal sheets, provides structural support for walkways, facades, and security barriers while allowing airflow and light penetration. Fiberglass mesh, often embedded in stucco or plaster, prevents surface cracks and improves durability.

Mesh materials are chosen based on strength, corrosion resistance, and flexibility. For example, galvanized or PVC-coated mesh is preferred for outdoor use, while stainless steel suits high-moisture environments. From galvanized concrete mesh to creating safety barriers, mesh is a versatile component in modern construction.

What is Fiber Mesh for Concrete?

Fiber mesh for concrete consists of synthetic, glass, or steel fibers mixed into concrete to improve its tensile strength, crack resistance, and durability. Unlike traditional rebar or wire mesh, fiber mesh disperses uniformly throughout the concrete, providing omnidirectional reinforcement and reducing shrinkage cracks as the material cures.

Common types include polypropylene fibers for crack control in slabs and pavements, and steel fibers for heavy-duty applications like industrial floors or tunnel linings. Fiber mesh simplifies construction by eliminating the need for manual mesh installation, saving time and labor costs. It also enhances impact resistance and longevity, making it ideal for driveways, sidewalks, and precast concrete elements. While not a full replacement for rebar in structural projects, fiber mesh is a cost-effective, low-maintenance solution for improving concrete performance.